Description

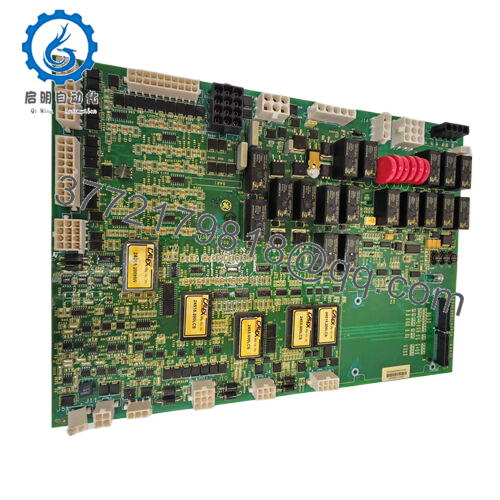

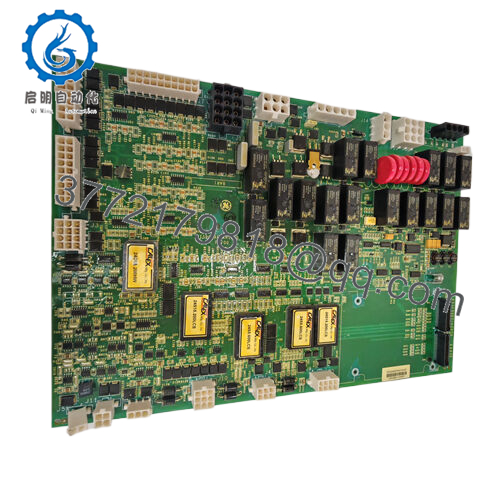

In the unforgiving realm of industrial automation, where analog signal acquisition must deliver unerring accuracy for parameters like temperatures, pressures, or flows to enable precise turbine sequencing and fault detection without the pitfalls of noise corruption or channel overloads, engineers often confront hurdles like limited input ranges, inadequate isolation for EMI-heavy turbine enclosures, or the inflexibility of non-scalable boards that require full system teardowns for expansions. The GE IS200AEPAH1AHD steps in as a high-density analog expansion processor assembly for GE’s Mark VI and Mark VIe Speedtronic systems, solving these by providing robust, multi-channel input conditioning tailored for gas/steam turbine control in process control environments. Imagine a combined-cycle power plant where exhaust gas temperatures and servo valve positions demand real-time monitoring across 16+ channels—if the processor introduces drift or cross-talk, you’d risk combustion imbalances, reduced efficiency, or protective trips that cascade into megawatt-hour losses and regulatory audits. This assembly is indispensable in such high-reliability scenarios, where its galvanic isolation and signal filtering ensure pristine I/O signal integrity, supporting modular VME chassis builds that extend turbine management without overhauling legacy control architectures.

The GE IS200AEPAH1AHD is a linchpin for facilities evolving turbine fleets, such as utilities or industrial cogeneration, where its compatibility with Mark VI’s triple-redundant framework allows seamless addition of ±10 V or 4-20 mA inputs without custom converters. By embedding metal oxide varistors for surge protection and opto-isolators for noise rejection, it counters common threats like voltage spikes or ground loops that erode precision in 50/60 Hz fields, aligning with goals of predictive diagnostics through diagnostic registers and jumper modes. In dusty, humid, or vibration-intense turbine halls, its surface-mount design and conformal coating prevent degradation, upholding API 670 compliance. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” resonate here—the GE IS200AEPAH1AHD empowers fault-tolerant analog handling, minimizing the engineering lift for channel scaling and ensuring consistent performance in environments where every analog reading safeguards generation and safety.

How the Product Works & Fits into a System

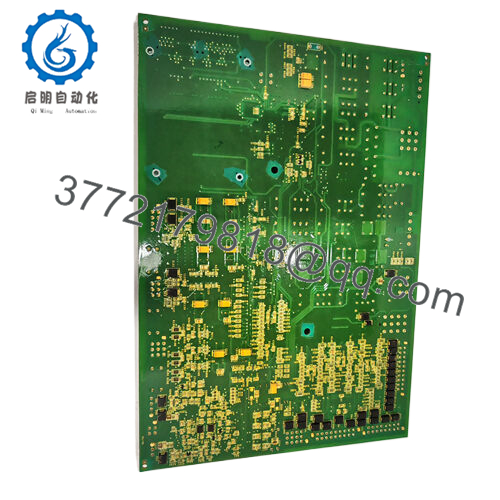

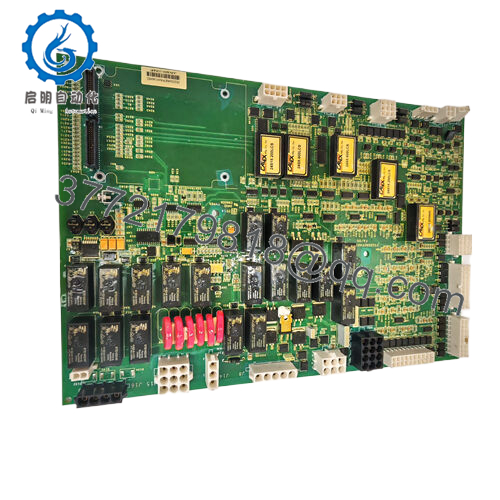

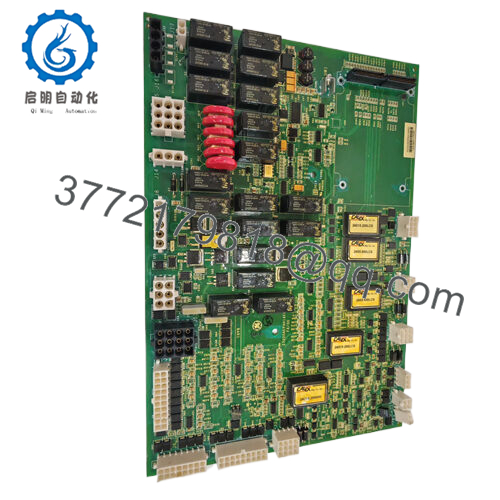

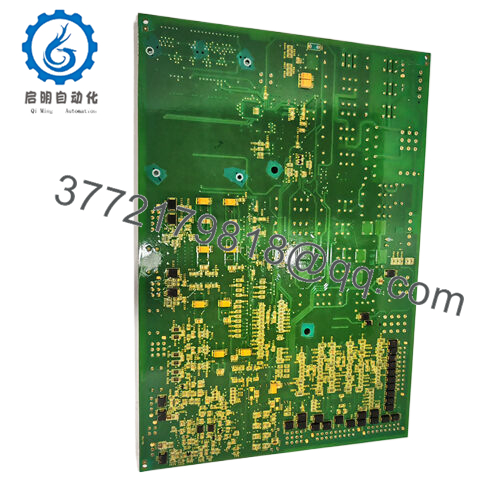

The GE IS200AEPAH1AHD functions as an analog input processor within the Mark VI/Mark VIe VME chassis, typically occupying a dedicated slot to interface field wiring via its terminal blocks and connectors, conditioning up to 16 differential inputs (e.g., ±10 V or 0-20 mA) before routing digitized values to the core controller via the IONet backplane. Positioned in the signal acquisition layer of the automation stack, it employs 16-bit A/D converters with programmable gain amplifiers for linearization and scaling, supporting redundancy by mirroring channels across R, S, and T cores for voting in TMR setups. This configuration interacts with upstream modules like the VPRO for proportional outputs or downstream exciters, drawing 28 VDC from the chassis while providing 1500 V isolation to block common-mode noise, and jumper-selectable modes for RTD or thermocouple support.

In operation, the assembly’s onboard DSP filters signals at 50/60 Hz rejection, with diagnostic bits flagging over-range or open-circuit faults reportable via Modbus TCP for SCADA integration, enabling real-time trending without external multiplexers. For instance, in a gas turbine application, the GE IS200AEPAH1AHD might acquire servo feedback voltages, applying cold-junction compensation for thermocouples before passing scaled data to the controller for fuel valve modulation—all while maintaining synchronization with speed probes for overspeed logic. Its 19 plug connectors and six varistors enhance surge resilience, and compatibility with ToolboxST software streamlines calibration. Rather than a mere digitizer, this processor actively conditions and validates, fitting into modular Mark VI architectures where input density matters, and reducing harness complexity for quicker field commissioning in the overall process control loop.

- IS200AEPAH1AHD

- IS200AEPAH1AHD

| Specification | Details |

|---|---|

| Model Number | IS200AEPAH1AHD |

| Brand | GE (GE Vernova) |

| Type | Analog Expansion Processor Assembly |

| Input Voltage | 28 VDC (via Mark VI chassis) |

| Operating Temp Range | -40 to +70°C |

| Mounting Style | VME rack slot (standoffs) |

| Dimensions | 13.3″ x 10.7″ (338mm x 272mm) |

| Weight | 2.0 kg |

| Interface/Bus | 19 plug connectors, terminal blocks, IONet backplane |

| Compliance | UL, CE, API 670, IEC 61508 (SIL 2) |

| Supported Protocols | Modbus TCP (via system) |

| Typical Power Draw | 15 W |

Real-World Benefits

Selecting the GE IS200AEPAH1AHD instills a signal fortress engineered for turbine extremes, where its 16-bit resolution and 1500 V isolation sustain long-term performance by preserving analog fidelity amid 100 g vibrations, letting servo positions track setpoints within ±0.1% even under 60 Hz harmonics from generators. In the field, this means combustion chambers stabilizing at optimal temps without drift-induced lean burns, enhancing fuel efficiency and extending hot-section life—pivotal for plants where accuracy curtails NOx emissions or output variability.

The assembly’s TMR-native design further alleviates strains, as redundant channels enable seamless core swaps during live runs, trimming engineering hours for maintenance teams and supporting predictive analytics that spot varistor wear early via register reads. By embedding surge suppression, it lowers false trip rates, boosting availability to 99.999% in SIL 2 applications where glitches could amplify hazards. Teams reap from this fortitude beyond specs: fewer spares for field repairs, faster root-cause via integrated diagnostics, and the assurance to densify inputs without proportional risks. Ultimately, the GE IS200AEPAH1AHD reframes analog acquisition from a noise-prone necessity to a precision enabler, fostering leaner turbine ops where reliability and generation converge.

Typical Use Cases

In gas turbine power plants, the GE IS200AEPAH1AHD conditions thermocouple inputs for exhaust monitoring, its connectors excelling in 70°C enclosures and EMI from exciters to guarantee high reliability for process control—critical system uptime endures through scaled signals that prevent hot spots during load ramps.

Steam turbine auxiliaries deploy the GE IS200AEPAH1AHD for pressure transducer interfacing, amid humid halls and 50 Hz fields; its filtering upholds process control precision, enabling valve sequencing without surge risks in variable-steam flows.

Aero-derivative turbines in industrial cogeneration harness the GE IS200AEPAH1AHD for vibration and temp arrays, routing analogs over harnesses in oily, jolt-prone exposures—its isolation delivers high reliability, optimizing loads without cavitation in dynamic, high-consequence process control.

Compatible or Alternative Products

IS200AEPAH1A – Base predecessor without HD revision, for legacy Mark VI retrofits.

IS200VPROH1A – Proportional output module companion for actuator extensions.

IS200EPCTH1A – Exciter power control terminal for voltage inputs.

IS200VCRH1A – Relay output card for alarm pairings in Mark VI chassis.

IS200TBCIH1C – General termination board alternative for non-analog I/O.

VPRO-I1 – Vibration protection relay for complementary monitoring.

IS215AEPAH1A – Mark VIe upgrade variant with enhanced density.

DS200TCQCG1A – Core control board for broader Mark V ties.

Setup Notes & Maintenance Insights

Before integrating the GE IS200AEPAH1AHD into your Mark VI chassis, verify VME slot assignment (typically R/S/T cores) and firmware sync (v13+ via ToolboxST) to preempt scaling errors, and calibrate inputs with a Fluke simulator at ±10 V for <0.1% linearity. Test harness resistance <0.5 ohms per channel with a loop tester, and confirm 28 VDC ripple under 100 mV via scope to avoid A/D noise; in humid halls, apply conformal coating to unused pins pre-torquing at 0.6 Nm. Ground the chassis to <0.1 ohm per NEC, and baseline varistor response with a 1 kV pulse generator, targeting <5% attenuation.

For the GE IS200AEPAH1AHD, quarterly checks include varistor integrity via DMM (>1 MΩ isolation)—replace if degraded, a 15-minute rack-open task in de-energized states. Monitor diagnostic registers monthly via HMI for over-range flags, probing channels with a multimeter for drift under 0.05%; in dusty locales, clean terminal blocks biannually with isopropyl, re-torquing as needed. Annually, during outages, inject simulated 4-20 mA faults to validate TMR voting under 100 ms, but offline: no live hazards. These API 670-aligned routines keep the assembly acute without turbine teardowns.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626