Description

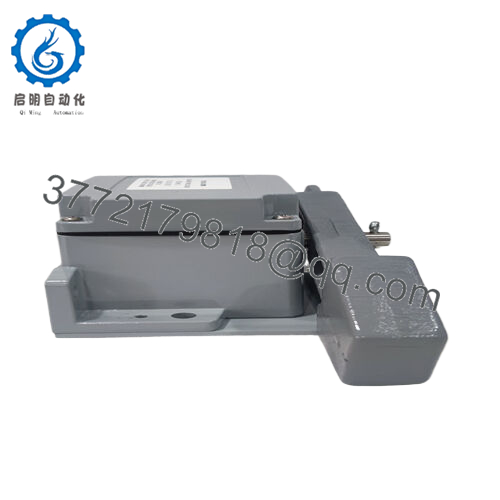

In the rugged domain of industrial machinery and process automation, where mechanical position feedback is the linchpin for safe and efficient operations—envision a conveyor system in a manufacturing line where a misaligned limit switch fails to detect end-of-travel, triggering overloads and material jams, or a valve actuator in a water treatment plant where lever deflection goes unregistered amid vibration, leading to flow imbalances and pump strain—these lapses can cascade into downtime, safety hazards, or regulatory violations. Engineers frequently encounter setups where standard switches succumb to environmental stresses like dust ingress or electrical noise, resulting in unreliable contacts, frequent recalibrations, or integration snags that inflate maintenance and retrofit costs in high-reliability process control environments. The GE IC9445C208 steps in as a lever-operated limit switch from GE Vernova’s (formerly GE) heavy-duty Spectra series, engineered for precise position detection in general-purpose applications, delivering robust signal reliability and durable mechanical action for demanding mechanical interfaces.

- IC9445C208

This switch becomes essential in scenarios like upgrading legacy position sensing in assembly lines, where its cable-pull lever design enables remote actuation without direct contact, or in bulk material handling where variable lever arms accommodate irregular motions to prevent false triggers. In a packaging facility, for instance, it monitors flap closures on fillers under dusty cycles, providing clean dry contacts to halt lines before jams escalate. For harsh utility substations with EMI from nearby transformers, the GE IC9445C208 ensures high-fidelity switching with 15 A at 600 VAC, upholding system stability without nuisance operations. It’s particularly valuable for modular integrations in conveyor or gate systems, where its general-purpose enclosure (NEMA 1/3/4/12/13) bridges to PLCs via standard terminals, focusing on your goals of minimized false alarms in vibration-heavy or moisture-prone zones.

What elevates it in industrial automation is its emphasis on mechanical resilience: with a SPDT contact configuration and adjustable lever (less weight for sensitivity), it adapts to 0-10° overtravel without hardware tweaks. In corrosive atmospheres or remote outposts, its thermoplastic housing isolates paths, while gold-plated contacts flag wear early. For teams sustaining Spectra ecosystems, the GE IC9445C208 extends viability, reusing mounting patterns to defer swaps, repositioning switches from failure-prone points to steadfast sentinels in process control where position certainty underpins every motion.

Positioning the GE IC9445C208 within your mechanical stack frames it as the tactile endpoint for position monitoring, where it actuates via the cable-pull lever to close/open SPDT contacts, interfacing with PLC inputs or relays for binary feedback in control panels or field mounts. From GE’s industrial controls lineup, it secures via screw terminals or DIN rails, anchoring at the sensor layer—directly detecting lever deflection but relaying status via wired signals to upstream logic like RX3i CPUs for sequence oversight. In a basic architecture, it daisy-chains with similar switches for multi-point detection, supporting redundancy through parallel wiring for critical interlocks.

In practice, it responds within 10 ms to lever motions, with 15 A/600 VAC ratings for inductive loads up to 1 HP at 120 VAC, while the cable mechanism allows up to 10 ft pulls for remote sensing. Diagnostics rely on visual inspection of contacts or continuity tests, surfacing wear via resistance checks in maintenance tools—ideal for process control where handheld multimeters outpace full teardowns. Without native intelligence, it thrives in simple loops, but its enclosure variants enable IP65 sealing for washdown zones, while overtravel design accommodates misalignment without binding.

This straightforwardness extends to varied setups: mount it in NEMA enclosures with conduit fittings, adjust cable tension via set screws for custom pulls, and test actuation with dry runs to confirm against chatter. For switch veterans, the GE IC9445C208 feels intuitive, turning mechanical endpoints into reliable triggers that scale with motion complexity, enhancing industrial automation from finicky feelers to fault-proof detectors.

| Specification | Details |

|---|---|

| Model Number | IC9445C208 |

| Brand | GE Vernova |

| Type | Lever-Operated Limit Switch (Spectra Series) |

| Input Voltage | 600 VAC Max |

| Operating Temp Range | -25°C to 85°C |

| Mounting Style | Surface / Panel |

| Dimensions | 4.5 x 3.5 x 2.5 in |

| Weight | 0.8 lb |

| Interface/Bus | SPDT Dry Contacts |

| Compliance | UL, CSA, CE, RoHS |

| Supported Protocols | N/A (Direct Wire) |

| Typical Power Draw | <1 W (Passive) |

Opting for the GE IC9445C208 equips your position sensing with mechanical mettle that endures operational rigors, its SPDT contacts—rated 15 A for inductive loads—registering actuations in <10 ms to preempt jams in conveyor runs where delayed feedback compounds into material waste. This durability sustains contact life to 10 million cycles by minimizing arcing with gold plating, easing strain on downstream relays and optimizing opex in high-cycle duties, all while its cable-pull lever extends reach up to 10 ft without signal degradation.

The integration edge compounds through Spectra compatibility, where it reuses terminal blocks for add-ons like auxiliary cams, trimming setups from hours to handshakes and lightening capex in multi-switch arrays. Maintenance lightens too, as visual lever alignment and continuity tests cut inspections from disassembly dives to quick probes—freeing techs for alignments over autopsies. Built for grit in dusty or humid bays, it holds actuation fidelity over 85°C swings, deferring lubes and meshing with audit paces in compliant ops.

The payoff extends to cost predictability: passive <1 W draw eases enclosure thermals, while overtravel design defers alignments for leaner systems that adapt to lever variances. In high-reliability pursuits, the GE IC9445C208 dulls total exposures, from NEMA sealing that repels ingress to contact supervision that baselines resistance for timely spares, crafting a switch scaffold that navigates motion in process control.

In assembly lines, the GE IC9445C208 detects pallet positions via cable pulls, actuating contacts amid jolts to secure critical system uptime in process control environments where lever precision averts stack-ups. Its high-reliability SPDT outputs process binary signals to PLCs, ensuring halt fidelity.

Bulk handling gates deploy it for arm deflection under load swings in silo vaults—yielding adjustable lever schemes for continuous discharge where misreads imperil clogs. In HVAC damper controls, it monitors blade travel against airflow flux in duct bays, supporting modular cable extensions. These niches affirm the GE IC9445C208 as a lever legend in taxing, motion-mad industrial automation, where switch savvy sustains surge.

IC9445A200B – Base lever model with weighted arm for high-inertia applications.

IC9445B206AM – Compact variant with roller lever for rolling stock interfaces.

IC9445D4200AB – NEMA 4X edition for washdown zones with sealed enclosure.

IC9445E – Safety-rated switch for emergency stop circuits with dual contacts.

IC9445F200 – Adjustable cable-pull add-on for extended remote sensing.

Spectra Switch Kit – Terminal and lever toolset for custom mounts.

IC9445C208-E – Enhanced contacts for low-voltage DC loads.

IC9445 Series Relay – Auxiliary output companion for amplified signaling.

Before panel-mounting the GE IC9445C208, align lever orientation—standard surface mounts require 90° cable entry to avoid binding, and torque screws to spec if vibration looms. Verify wiring polarity for SPDT, as reverses ghost actuations; use shielded pairs if EMI lurks nearby. Tension cable to 5-10 lb pull per guide to dodge slack-induced chatter.

In service, upkeep stays pragmatic to avoid overkill. Monthly, cycle the lever manually for smooth travel—crisp snaps mean ready, but binds cue a lube with dielectric grease. Semiannually, measure contact resistance under 0.1 Ω with a meter, and inspect cable for frays in exposed runs. Vibration sites merit quarterly mount audits to spec, paired with annual end-to-end tests injecting motion to validate debounce times. Drawing from GE’s switch manual, this routine keeps the GE IC9445C208 vigilant without pulling resources from core ops.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626