Description

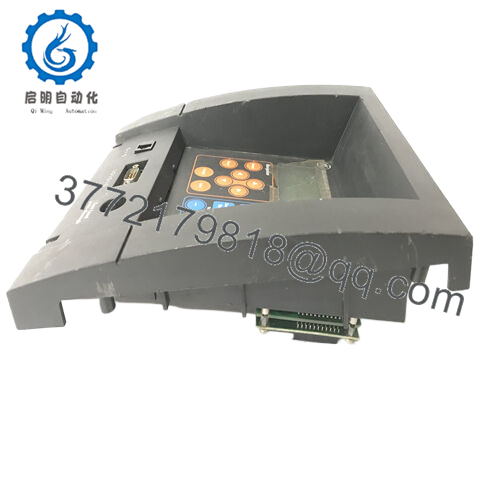

GE IC752SPL013-BA EX2100 is an essential part of the GE EX2100 excitation control system. Its main function is to establish an interface between the operator and the underlying excitation control mechanism. This panel allows operators to input commands, monitor system parameters, and receive real-time feedback on the excitation status of the generator.

IC752SPL013-BA EX2100

In the EX2100 overall system, IC752SPL013-BA EX2100 is connected to the main control module, which is responsible for processing data from various sensors. These sensors monitor the line current, stator output voltage, and other key parameters of the generator. Based on these data, the control module calculates the appropriate excitation level required to maintain stable operation of the generator. The IC752SPL013-BA EX2100panel then displays this information to the operator in an easily understandable format. It also allows operators to override certain settings or initiate specific control operations when necessary.

IC752SPL013-BA EX2100

Technical specifications:

Model IC752SPL013-BA EX2100

Brand GE

Type excitation control interface panel

Working voltage 220 V

Output frequency 50 kHz

Certification meets relevant industry standards

Series IC752SPL013

Material Code IC752SPL013- BA

Dimensions length x width x height (millimeters): 450 x 280 x 210

Weight 2.4 kg

Connect the interface to the EX2100 control module; Provide an interface for operators

Compatibility designed specifically for use with GE EX2100 excitation control system

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

IC752SPL013-BA EX2100

Main features and advantages:

Its precise voltage regulation capability ensures that the power generation equipment operates within the optimal voltage range. This not only protects sensitive electrical equipment from voltage related damage, but also improves the overall efficiency of power generation. In large industrial factories with multiple power consuming devices, the stable voltage supply provided by the EX2100 system (IC752SPL013-BA EX2100 panel facilitated control) can prevent equipment failures and production interruptions.

The ability of this system to effectively manage reactive power helps optimize the power factor of the power grid. By adjusting the excitation of the generator, the EX2100 system can ensure a power factor close to 1, thereby reducing energy loss during power transmission and distribution. This saves costs for power generation companies and improves the efficiency of energy resource utilization. The modular and flexible design of the EX2100 system, with the IC752SPL013-BA EX2100 panel as an important component, makes it easy to integrate into new power generation units and also allows for retrofitting of existing systems. This adaptability makes it an economical and efficient solution for power generation facilities to upgrade their excitation control capabilities without undergoing large-scale renovations.

IC752SPL013-BA EX2100

Application areas:

In gas-fired power plants, the EX2100 system (IC752SPL013-BA EX2100 panel for operator interaction) monitors and adjusts the excitation of the generator in real-time based on load demand. This enables power plants to quickly respond to changes in electricity consumption and maintain grid stability.

Industrial facilities with their own power generation systems can also benefit from GE IC752SPL013-BA EX2100. A large manufacturing factory with multiple production lines may use this system to control the generators that supply power to the factory. The precise excitation control provided by this system helps to provide stable power supply for production equipment, minimizing the risk of equipment failure caused by voltage fluctuations. In addition, the ability to efficiently manage reactive power reduces the overall energy consumption of the factory, thereby saving costs.

IC752SPL013-BA EX2100

Installation and maintenance:

Before installing the GE IC752SPL013-BA EX2100 interface panel, it is essential to ensure that the entire EX2100 excitation control system is properly configured. This includes verifying the connection between the power transformer or excitation transformer and the system, as well as checking the integrity of the sensor connections that provide data to the main control module. The IC752SPL013-BA EX2100 panel should be installed in a location that is easily accessible to the operator and has appropriate environmental conditions (such as suitable temperature and humidity levels) to ensure reliable operation.

For maintenance, the display screen and control buttons of the panel should be checked regularly to ensure their normal operation. Regular testing should also be conducted on the communication link between the IC752SPL013-BA EX2100 panel and the main control module to check for any data transmission issues. If there are available software updates, they should be applied promptly to maintain system security and optimize performance. In addition, the overall EX2100 system (including power conversion modules and protection circuits) should be maintained according to GE’s recommended maintenance plan. This includes checking for signs of wear or damage to components such as thyristor bridges, cooling fans, and DC contactors.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626