Description

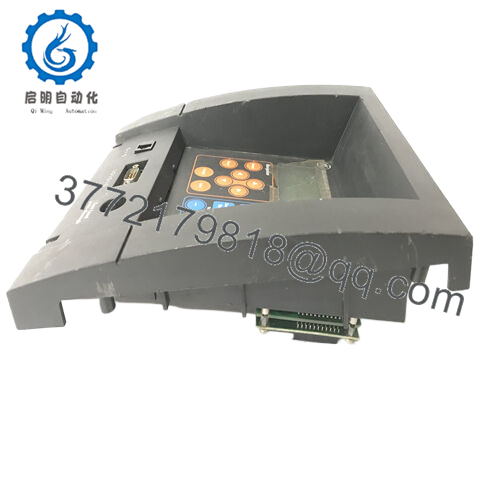

In the electrified heart of power generation facilities, where synchronous generators must maintain razor-sharp voltage regulation amid grid volatilities, load rejections, or renewable infusions—yet operators contend with opaque interfaces that obscure real-time diagnostics and parameter tweaks, risking prolonged faults or suboptimal synchronization—engineers demand intuitive access points that democratize control without compromising the integrity of excitation loops. The GE IC752SPL013-BA EX2100 fulfills this as a dedicated excitation control interface panel from GE’s EX2100 series, purpose-built to streamline human-machine interaction in industrial automation by furnishing a tactile, on-the-spot portal for monitoring and commanding generator excitation systems in process control applications. Picture a hydro plant navigating a sudden turbine overspeed: excitation currents spike erratically, but without a localized HMI, troubleshooting devolves into remote tool hunts or panel dives, amplifying response times that could cascade to equipment stress or blackout ripples. This panel counters by presenting key metrics—such as field voltage, stator output, and regulator status—via a crisp 16-character alphanumeric display, while its 12-button keypad enables swift adjustments like setpoint shifts or mode toggles, all tied to the EX2100’s core logic for high reliability in I/O signal oversight. It’s essential in modular integration contexts, like retrofitting legacy exciters for digital front-ends or expanding bay controls in fossil-fired stations where system stability hinges on operator agility amid 24/7 thermal regimes. By attuning to the engineer’s ethos of accessible diagnostics, the GE IC752SPL013-BA EX2100 dissolves the veil of complexity, allowing field crews to intervene decisively without invoking full-system lockdowns or proprietary laptops. In nuclear steam cycles, it proves invaluable during startup sequences, flashing fault codes to expedite degaussing amid radiation-hardened enclosures. This isn’t peripheral plating; it’s a conduit to command, curtailing the latency in fault isolation that erodes MTTR in regulated realms. For those evaluating HMIs in excitation architectures, the GE IC752SPL013-BA EX2100 distinguishes itself through its rugged simplicity and bus-native fluency, mapping a direct path to resilient process control that aligns with IEEE 421 standards sans elaborate overlays. Whether anchoring a standalone exciter skid or meshing into a fleet-wide SCADA, it equips teams with the immediacy to convert crises into calibrated continuity.

The GE IC752SPL013-BA EX2100 integrates as the front-facing sentinel in the EX2100 enclosure, a panel-mounted HMI that bridges operator inputs to the system’s regulator brains via an internal ribbon bus, channeling commands and echoes with the fidelity of a native peripheral. Affix it to the cabinet fascia, and it engages: the vacuum-fluorescent display renders scrolling menus for parameter views—like AVR gains or PSS tuning—while the tactile keypad dispatches keypresses to the main controller for execution, encompassing mode selections from manual to auto-tracking without scan interruptions. Positioned at the human edge of the automation stack—flanking the power bridge below yet feeding supervisory networks above—it filters interactions, enforcing password tiers to safeguard setpoint mods while relaying diagnostics like overexcitation alarms or bridge faults through serial handshakes to Toolbox interfaces. In redundant setups, it mirrors states across duplex regulators, presenting unified views that mask failover transients, a bulwark for scenarios where a glitch could unseat synchronization. Diagnostics dwell intrinsically, with LED backlights cueing active faults or comms health, queuing event buffers for download sans enclosure exposure. Pair it with I/O gateways or bridge drivers in the rack, and it enriches the QNX kernel with operator-vetted directives, supporting DNP3 for utility uplinks or Modbus for HMI overlays. Its forthright finesse emerges in the menu navigation; no steep learning arcs—preloaded prompts guide setpoint entries or calibration runs, condensing familiarization from shifts to sessions. For blended plants layering Ethernet trunks over legacy RS-485 spines, the panel’s isolation buffers user noise, forestalling the ingress of key chatter that skews regulator polls. Collectively, it frames a human-centric hierarchy—interface for intuition, core for computation, canopy for collation—spawning symbiotic spheres that evolve from isolated exciters to orchestrated outages. This interplay not only accelerates anomaly acknowledgments but also invites firmware alignments, harmonizing with escalating cyber perimeters.

| Specification | Details |

|---|---|

| Model Number | IC752SPL013-BA EX2100 |

| Brand | GE (General Electric) Fanuc |

| Type | Excitation Control Interface Panel (HMI/Keypad) |

| Input Voltage | 24 V DC ±10% |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | Panel-mounted in EX2100 cabinet |

| Dimensions | 10.5 in × 10.0 in × 3.5 in |

| Weight | 1.54 kg |

| Interface/Bus | Internal ribbon bus; RS-485 serial |

| Compliance | CE, UL, CSA; IEEE 421 compatible |

| Supported Protocols | Modbus RTU, DNP3 (system-level) |

| Typical Power Draw | 8 W |

Incorporating the GE IC752SPL013-BA EX2100 yields a profound pivot in operator empowerment, as its alphanumeric clarity—coupled with keypad tactility—renders excitation transients transparent through enclosure eddies or humid hazes, envisioning a coal-fired unit where PSS damping views avert hunt oscillations, sustaining grid ties that salvage stability and shave frequency fines. This lucidity lends to lookahead layers; by surfacing regulator traces in menu scrolls, it equips shifts to correlate field currents with stator slips ere they escalate, habitually hastening harmony by halves in harmonic hunts. Deployment demands dwindle as the panel’s cutout congruence mates with EX2100 fascias sans fabrication frays, infusing interactivity via a latch lock over label labyrinths, nesting nuances into notch turns.

Steadiness in scrutiny seals its stature, with display refresh under 100 ms that anchors views amid voltage variances—crucial for hydro governors where ramp rejections could ripple rotors, riveting responses that reclaim ramp rates without recoil. Stewardship simplifies to sighted sweeps; fault codex cues consolidate cues to consoles, demystifying a bridge bypass in blinks over buffer browses, which might economize escalation episodes by echelons in expansive estates. Forged for fortitude with sealed membranes and thermal veils, it pledges pixel-pure persistence that outpaces fragile fronts, vesting veracity in voltage vicissitudes. For forecasters framing fleets, its bus affinity eases exciter ensembles, warding waves like waveform wards without warp wrenches. At anchor, the GE IC752SPL013-BA EX2100 reframes reckoning from remote to resonant, apportioning the acuity and approachability that exalt excitation enclaves from essential to exemplary.

- IC752SPL013-BA EX2100

- IC752SPL013-BA EX2100

The GE IC752SPL013-BA EX2100 lodges lastingly in steam turbine annexes at baseload plants, where it tenders setpoint scrolls and mode maneuvers to modulate field fluxes, reinforcing critical system uptime via bus-bound briefs that brave boiler blasts and bypass bursts demanding decisive dials. In these process control environments, its codex condenses 20+ faults for flicker-free fixes, quelling quirks that quench quotas. Gas turbine gensets in peaking pods plot a parallel plot, with the GE IC752SPL013-BA EX2100 in exciter eaves polling PSS parameters amid fuel flickers and frequency frolics, where continuous uptime underpins peak prowess. Here, serial synapses sidestep single-thread snags, affirming I/O signal high reliability for surge-safe starts. Offshore platform alternators notch the narrative, the panel in sync-check stations sequencing soft lands against wave whacks and wind whims, enabling e-stop echoes that economize evacuations in equatorial eddies. Spanning these used in power plants and process control environments, it harnesses harsh conditions, heightening high reliability for generators grappling grid gyrations.

IC752SRL013-BA – Relay logic variant for enhanced fault latching in EX2100 simplex setups.

IC752SPL013-BB – Updated revision with expanded menu depth for PSS tuning diagnostics.

EX2100-DFM – Digital front-end module complementing the panel for retrofit AVR upgrades.

IC200ALG320 – Analog input card extending exciter I/O for field current monitoring with the IC752SPL013.

EX2100-PFB – Power feedback bridge interface pairing for voltage regulation alongside HMI panels.

IC693CPU374 – Series 90-30 CPU as a legacy migration path for EX2100 host integrations.

EX2100-SVM – Static voltage module for high-current exciters enhanced by IC752SPL013 controls.

Before affixing the GE IC752SPL013-BA EX2100 to your cabinet cutout, calibrate the gasket seal—EX2100 enclosures vary by rev, so a template trace ensures flush fits that fend fog without frame flex; a bead of RTV at edges averts ingress that ghosts key ghosts. Torque the mounting studs to 2 Nm post-alignment; undertight yields rattles in vibratory vaults, spiking contact chatter that mimics menu malfunctions. Firmware fellowship follows—poll the main controller’s version via RS-485 prior to sync, as offsets over 1.0 invite handshake halts that hush the display; stage the update through a serial cradle for seamless sutures. Nurture nestles into nominal nods: bimonthly backlight checks unearth dimming in dusty drifts, a simple voltage tap revives if below 22 V DC to reclaim legibility. Semiannual keypad stress, cycling all keys with a script sim, assays adhesion arcs sans service sags—log lags past 50 ms to refresh membranes preemptively. In corrosive coasts or coolant-close climes, membrane moats merit quarterly quizzes; haze hiking resistance over 10 MΩ cues conductive cleans with isopropyl to restore responsiveness. These aren’t ordinances—they’re the observed observances that orchestrate the panel’s poise, orienting your operations to oversight over overhauls.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626