Description

- Real-World Use & Application Scenarios

Where is this product used and why?

In industrial control rooms and machine cabinets, reliable power is non-negotiable. The GE IC698PSA100D acts as the essential energy source for backplanes, CPUs, I/O blocks, and communication modules within PACSystems RX7i environments, delivering clean, stable power across demanding operations. It shines in automotive assembly lines, packaging and bottling lines, process control plants, and material handling systems where uptime, minimal electrical noise, and consistent performance directly impact throughput and quality. Technicians rely on this module to convert incoming line voltage into the precise 5 VDC reference the control hardware needs, supporting deterministic operation of controllers and I/O networks. In complex automation architectures, a dependable power supply like the IC698PSA100D reduces ripple, minimizes brownouts, and helps protect sensitive electronics from voltage spikes. This model is frequently referenced in control-system schematics and maintenance manuals as the “power source” that keeps RX7i backplanes energized, enabling reliable start-up sequences and stable long-duration operation. Many engineers emphasize its role in legacy and retrofit projects where PACSystems RX7i hardware coexists with newer devices, ensuring backward compatibility and a common power delivery standard for mixed hardware generations.- IC698PSA100D

- IC698PSA100D

- Product Introduction & Positioning

Overview of the product’s definition, role, and system compatibility

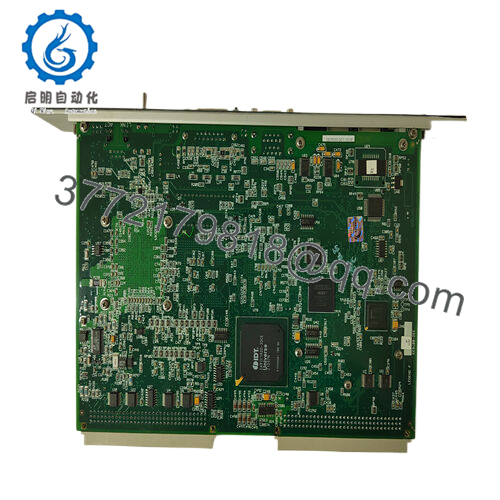

The GE IC698PSA100D is a high-capacity power supply module designed specifically for PACSystems RX7i configurations. It functions as the primary backplane power source, converting standard AC line voltage into a tightly regulated 5 VDC supply that powers the processor, I/O modules, and fieldbus interfaces within the RX7i ecosystem. This module is a keystone in RX7i sequenced architectures, providing stable power to the central controller and distributed peripherals, which ensures predictable timing and reliable data integrity across subsystems. It is built to integrate seamlessly with RX7i backplanes, supporting the system’s modular approach to expansion and upgrading. For engineers and integrators, the IC698PSA100D offers proven endurance in industrial environments, straightforward installation within the leftmost backplane slot, and long-term availability to minimize lifecycle risk. The model designation is highlighted here as GE IC698PSA100D to reinforce its identity and compatibility across RX7i deployments. - Key Technical Features & Functional Benefits

GE IC698PSA100D brings robust performance and practical robustness to control cabinets. Its primary strength lies in delivering a reliable 5 VDC supply with sufficient headroom to power the RX7i backplane and all attached CPUs and I/O blocks, which helps sustain stable control loops and data integrity under load transients. The hardware design emphasizes a compact footprint appropriate for crowded enclosures, with mounting aligned to the RX7i leftmost slot convention, simplifying panel layout and serviceability. Compatibility is straightforward within the PACSystems RX7i family, ensuring clean integration with GE’s engineering tools, diagnostics, and firmware management workflows, while providing predictable behavior in mixed hardware environments. Long-term reliability is supported by a design that minimizes ripple and noise and is proven in continuous operation across varied industrial settings. The IC698PSA100D stands as a dependable backbone component for mission-critical automation tasks, whether in greenfield installations or retrofits that require a consistent, maintainable power topology. - Detailed Technical Specifications

Parameter | Value

Model | IC698PSA100D

Brand | GE Fanuc Emerson

Type | Power supply module for PACSystems RX7i

Power Supply | Converts AC line voltage to 5 VDC backplane power

Operating Temperature | Standard industrial: typically -40 to 85 degrees Celsius (depending on enclosure and airflow)

Mounting | Leftmost slot on RX7i backplane

Dimensions | Fits RX7i module footprint (specific footprint per original GE RX7i specs)

Weight | Moderate panel-mount weight (model-dependent)

Interfaces | Backplane power interface; no external data interfaces

Certifications | Typically CE and UL listed for industrial automation environments

Cooling | Passive/air-cooled within enclosure; heatsinking as required by installation

Environmental Rating | NEMA/IEC-compliant industrial enclosure compatibility - Related Modules or Compatible Units

- IC698PSA350 – Higher power variants within the same RX7i power family for larger backplanes. This model connects in the same power infrastructure as IC698PSA100D.

- IC698PSA200 – Mid-range power option with similar backplane integration for different RX7i configurations.

- IC698PSA300 – Expanded power supply variant designed for heavier duty RX7i installations.

- IC698PSD300 – Power distribution module that pairs with the PSAs to manage distribution to multiple RX7i rails.

- IC698CAM001 – Communication-related module that can sit alongside the PSA units within the RX7i ecosystem to extend I/O capabilities.

- IC698CRI001 – Control interface module designed to facilitate firmware upgrades and diagnostics within the RX7i platform.

- IC698JDR – Local diagnostics and monitoring module that works with the RX7i backplane to provide health data for preventive maintenance.

- Installation Notes & Maintenance Best Practices

Pre-installation considerations

Ensure the RX7i chassis has adequate clearance for the leftmost PSA slot, with proper ventilation and cable management to prevent heat buildup. Verify that the enclosure grounding is solid and that the AC mains supply satisfies the required voltage range and protection (fusing, surge suppression). Confirm compatibility with the existing RX7i backplane revision and confirm any required jumpers or alignment procedures specified by GE’s engineering guides. Plan for space for the power module’s heat dissipation, and ensure that nearby components do not obstruct airflow or create EMI concerns.

Maintenance best practices

Establish a quarterly inspection routine to verify mechanical mounting integrity, connector seating, and signs of discoloration from heat. Monitor backplane power rails and load distribution with diagnostic tools to detect drift or ripple beyond tolerance. Keep firmware and documentation up to date, coordinating with GE’s service channels for any recommended revision updates. Maintain a spare PSA module for quick field replacement, and document all service actions within the asset database to support traceability and audits.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626