Description

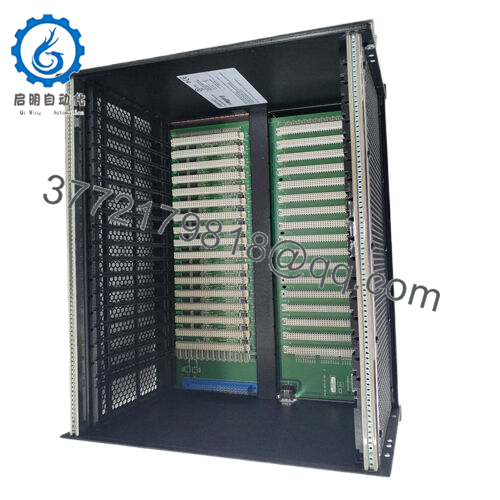

In the expansive ecosystem of programmable automation controllers, where chassis limitations can constrain modular expansions and scalability—envision a large-scale water treatment facility where insufficient rack slots force fragmented I/O distributions, complicating wiring and risking signal integrity amid pump sequencing, or a discrete manufacturing plant where backplane overcrowding leads to thermal hotspots and diagnostic silos, amplifying commissioning times and fault isolation in process control environments—these constraints erode system flexibility and drive up engineering overhead. Such hurdles are prevalent in high-density PACSystems deployments, where legacy racks falter under dense module loads, spawning integration bottlenecks, airflow issues, or maintenance complexities that escalate opex and compliance burdens in high-reliability industrial automation. The GE IC698CHS217 addresses this as a 17-slot front and rear mount rack from GE Vernova’s (formerly GE Fanuc) PACSystems RX7i series, engineered to host a broad array of CPUs, I/O, and specialty modules on its serial backplane, ensuring seamless power distribution and signal routing for robust, expandable control architectures.

This rack proves vital in applications like consolidating legacy Series 90-70 systems into unified high-availability setups, where its dual-access design (front for modules, rear for power) enables in-service maintenance without full de-energizing, or in power generation tie-ins requiring dense I/O for synchronous motor controls. In a petrochemical blending station, for instance, it accommodates up to 17 modules for multi-loop PID handling under corrosive vapors, delivering high-reliability backplane connectivity to prevent data stalls that could skew recipes. For offshore platform DCS with vibration-heavy cabinets, the GE IC698CHS217 supports remote expansion up to 15 meters via serial cables, upholding system stability without compromising on NEMA 1 enclosure ratings. It’s a cornerstone for scalable builds in multi-rack configurations, where its compatibility with RX7i CPUs bridges to SCADA without proprietary adapters, emphasizing goals like modular diagnostics in EMI-saturated or thermal-variable enclosures.

IC698CHS217

What elevates it in process control is its emphasis on architectural endurance: with 0.8-inch module spacing for optimal airflow, it adapts to up to 17 single-width modules without derating. In dust-laden plants or remote grids, its passive cooling isolates heat, while bus arbitration preempts contention. For teams modernizing RX7i ecosystems, the GE IC698CHS217 facilitates persistence, reusing mounting patterns to minimize downtime, repositioning racks from capacity chokepoints to extensible foundations in industrial automation where slot density powers every expansion.

When deploying the GE IC698CHS217 in your PACSystems framework, envision it as the scalable spine for RX7i chassis, where it interconnects modules via the serial backplane for power and data sharing, supporting up to 17 slots for CPUs like IC698CPE030 or I/O like IC698ALG230 in front/rear mount configurations. This rack installs in standard 19-inch panels via DIN or wall mounts, positioning at the core layer—directly hosting field interfaces but extending via serial cables (up to 15 m) to remote drops for distributed I/O. In a multi-tier stack, it links with expansion racks for up to 38 slots total, leveraging the backplane for hot-swappable modules in high-availability loops.

In routine, it distributes +5 VDC/+15 VDC/+24 VDC rails with bus arbitration for seamless module handoffs, while serial expansion enables daisy-chaining without latency spikes. Diagnostics rely on visual slot indicators or host tools, surfacing power faults or insertion errors in Proficy for remote review—essential in process control where rack-level audits outpace physical inspections. Without native redundancy, it pairs with dual power supplies for failover, ensuring uptime in paralleled ops, while its firmware supports online module recognition without reboots.

This modularity reaches hybrid environments: secure it in NEMA 1 enclosures with forced ventilation, populate slots via guided insertion for custom densities, and test backplane integrity with continuity checks to affirm against crosstalk. For rack veterans from Series 90-70, the GE IC698CHS217 feels intuitive, evolving single chassis into expansive arrays that adapt to module proliferation, enhancing industrial automation from slot-starved skeletons to robust scaffolds.

| Specification | Details |

|---|---|

| Model Number | IC698CHS217 |

| Brand | GE Vernova |

| Type | 17-Slot Front & Rear Mount Rack (PACSystems RX7i) |

| Input Voltage | +5 VDC, +15 VDC, +24 VDC (via Power Supply) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | 19″ Panel / DIN Rail |

| Dimensions | 16.5 x 5.1 x 14.7 in |

| Weight | 8.5 lb |

| Interface/Bus | Serial Backplane |

| Compliance | CE, UL, RoHS |

| Supported Protocols | RX7i Internal Bus |

| Typical Power Draw | 50 W (Rack Only) |

Opting for the GE IC698CHS217 arms your control backbone with unyielding slot capacity that defies expansion entropy, its 17-module layout—spaced at 0.8 inches—accommodating dense I/O without thermal throttling, preserving scan fidelity in high-density setups where overcrowding erodes determinism and spawns faults. This scalability sustains system life by enabling phased module adds, easing strain on CPUs and optimizing capex in evolving plants, all while its rear power access minimizes intrusion during live ops.

The deployment merit swells with RX7i synergy, where it reuses serial cables for remote drops up to 15 m, paring integrations from weeks to wiring and softening opex in multi-rack fleets. Maintenance refines via backplane self-tests that log insertions for proactive audits, truncating hunts from slot dives to software sifts—unleashing crews for configurations over crises. Forged for bays laced with ether or grit, it anchors bus integrity over 60°C cycles, forestalling alignments and meshing with uptime mandates in compliant realms.

The vista unveils synergy boosters—passive 50 W footprint eases PSU sizing, while front/rear access defers cabling for agile enclosures that bend to module booms. In high-reliability quests, the GE IC698CHS217 curtails pooled perils, from serial isolation that quells contention to slot supervision that baselines loads for spares, sculpting a rack web that braves barrages in process control.

In utility SCADA, the GE IC698CHS217 hosts breaker I/O modules, interconnecting signals amid switchyard hum to lock critical system uptime in process control environments where slot density averts logic silos. Its high-reliability backplane processes I/O signals from CPUs, ensuring scan cohesion.

Pharma batch controllers deploy it for recipe expansions under sterile swings in clean bays—yielding serial-extended paths for nonstop synthesis where overcrowding imperils precision. In solar inverter farms, it anchors control racks against tracker variances in sun-baked expanses, enabling modular CPU shares. These spheres acclaim the GE IC698CHS217 as a chassis champion in brutal, density-driven industrial automation, where rack rigor endures ebb.

IC698CHS017 – 17-slot wall mount variant for panel-constrained setups with similar capacity.

IC698CHS109 – 9-slot panel mount rack for compact core applications.

IC698CHS009 – 9-slot rear mount alternative for power-heavy enclosures.

IC698CHS117 – 17-slot side mount for vertical rack integrations.

IC698CPE030 – High-performance CPU companion for RX7i logic execution.

IC698ALG230 – Analog input module add-on for field signal expansions.

IC698ACC300 – Power supply mate for stable +24 VDC in populated racks.

IC698CMX016 – Control Memory Xchange module for inter-rack communication.

Before rack-populating the GE IC698CHS217, gauge enclosure clearance—19-inch mounts demand 4U height with 2-inch vents to curb hotspots, and torque screws to spec if vibration looms. Verify backplane continuity across slots, as breaks ghost modules; use a tester if extending serially. Allocate +24 VDC feeds with <5% ripple, as surges tax modules; buffer with regulators if PSUs nearby hum.

In the field, vigilance keeps it sharp with targeted checks that fit rotations. Monthly, scan slot indicators for insertion flags—full occupancy without blinks clears decks, but alerts cue a serial scan to trace power drops. Semiannually, reseat modules for contact integrity and run a backplane self-test per guide to affirm bus speeds under load. For dusty or humid spots, a quarterly soft brush of edges wards oxide, paired with annual rack-wide sims to validate expansion cable latency below 15 m. Leaning on GE’s RX7i handbook, these practices embed the GE IC698CHS217 as a self-reliant scaffold, demanding little while yielding much in chassis oversight.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626