Description

In the unforgiving world of industrial automation, where a CPU failure in a continuous process can trigger cascading shutdowns, product loss, or safety hazards, the tolerance for single-point vulnerabilities is zero. Engineers overseeing high-availability systems—whether in oil refineries, power generation, or pharmaceutical production—regularly contend with the risk of unscheduled downtime from hardware faults, the complexity of manual failover procedures, or the data inconsistencies that arise when redundant controllers drift out of sync. These challenges not only erode operational resilience but also inflate costs through redundant spares, extended recovery times, and compliance audits. The GE IC695RMX128-DG delivers a decisive countermeasure as a 128 MB Redundancy Memory Xchange (RMX) module for GE RX3i PACSystems, enabling synchronized, bumpless CPU failover with zero data loss in hot-standby configurations.

Visualize a pipeline compressor station where dual RX3i CPE400 controllers manage flow and pressure, or a sterile filling line where any logic interruption voids an entire batch—the GE IC695RMX128-DG becomes mission-critical when continuous uptime and data integrity define success. It resolves synchronization bottlenecks by providing a dedicated, fiber-optic Reflective Memory network that mirrors %R, %AI, %M, and %G memory between primary and secondary CPUs at 2.1 Gbps, ensuring identical states even during high-speed scan cycles. In broader industrial automation contexts, it supports predictive failover by monitoring partner health via heartbeat packets, triggering automatic switchover in under 10 ms upon fault detection. For architects, key considerations include its 128 MB capacity (supporting up to 64K %R words), single-slot footprint, and LC fiber connectors—specs that govern program size, cable runs, and redundancy topology. By eliminating these high-availability pain points, the GE IC695RMX128-DG transforms dual-controller setups into a unified, self-healing system, delivering seamless continuity and audit-ready data fidelity in life-critical process control.

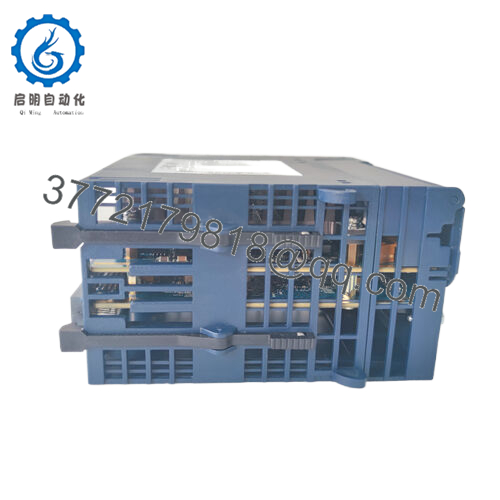

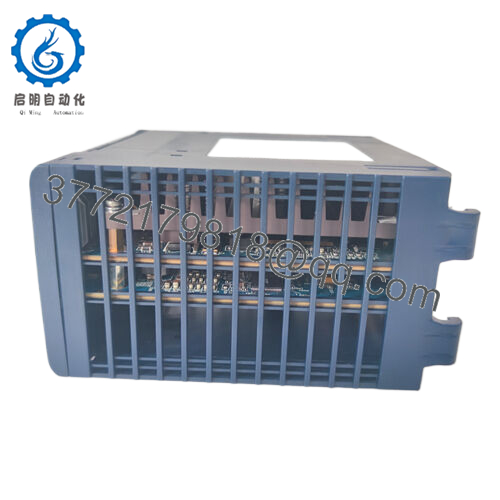

Integrating the GE IC695RMX128-DG into an RX3i redundancy architecture is like installing a real-time mirror between twin brains—it occupies any I/O slot in each controller’s universal backplane (primary and secondary), linking via duplex LC fiber (50/125 or 62.5/125 µm) up to 300 meters apart. Each module hosts a 128 MB DDR buffer and a 2.1 Gbps fiber transceiver, continuously broadcasting write operations from the active CPU to its partner with sub-microsecond latency. Synchronization is automatic: upon power-up, the backup RMX pulls the full memory image from the primary in <2 seconds; thereafter, only delta changes propagate, minimizing fiber bandwidth.

In the redundancy stack, it sits parallel to the CPUs (e.e., dual IC695CPE400s with IC695RMM002 redundancy link modules), forming a closed Reflective Memory ring with deterministic data reflection—no polling, no acknowledgments, no CPU overhead. Diagnostics flow via front-panel LEDs (LINK, SYNC, FAULT) and %S status bits: green LINK confirms fiber continuity, SYNC verifies data coherence, and FAULT flags buffer overflow or partner loss. Failover is bumpless—upon primary CPU fault, the secondary assumes control within one scan, retaining all I/O states, timers, and PID integrals. Picture the sync path: a pressure loop writes 512.3 to %AI100 on the primary; the GE IC695RMX128-DG replicates it to the backup in <1 µs; if the primary loses power, the backup continues the loop at 512.3 with zero disruption. For deployment, its hot-swap design and Proficy auto-discovery streamline commissioning, making the GE IC695RMX128-DG the cornerstone of RX3i high-availability process control.

| Specification | Details |

|---|---|

| Model Number | IC695RMX128-DG |

| Brand | GE (Emerson) |

| Type | 128 MB Redundancy Memory Xchange |

| Input Voltage | 5 V DC (backplane) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | RX3i Universal Backplane Slot |

| Dimensions | 5.57 x 1.26 x 5.12 in (141.5 x 32 x 130 mm) |

| Weight | 0.66 lbs (0.3 kg) |

| Interface/Bus | RX3i Backplane / Duplex LC Fiber |

| Compliance | CE, UL, CSA, ATEX |

| Supported Protocols | Reflective Memory (2.1 Gbps) |

| Typical Power Draw | 600 mA @ 5 V DC |

Choosing the GE IC695RMX128-DG delivers immediate continuity and long-term confidence—its 2.1 Gbps fiber link synchronizes 128 MB in <2 seconds on startup and maintains coherence during 500 Hz scans, ensuring zero data loss even in motion control or fast batch sequences. Diagnostics enable predictive maintenance: a degrading fiber link shows increasing CRC errors in %S registers weeks before failure, prompting a preemptive cable swap during planned downtime.

Failover performance is unmatched—sub-10 ms switchover preserves PID windup, timer accuracy, and I/O states, eliminating the “bump” that plagues warm-standby systems. Commissioning is streamlined: Proficy’s redundancy wizard auto-configures RMX nodes, memory maps, and failover logic in one pass, cutting setup from days to hours. Over the lifecycle, the module’s hot-swap capability and field-replaceable fiber transceivers defer obsolescence—upgrade from a 64 MB RMX with a 30-second swap, no logic changes. It’s a redundancy solution that compounds value—seamless failover, predictive alerts, and scalable memory—making the GE IC695RMX128-DG the gold standard for RX3i high-availability process control.

The GE IC695RMX128-DG powers turbine control skids in power plants, where dual RX3i CPUs manage governor and excitation loops, achieving <5 ms failover to prevent grid trips. In chemical reactors, it synchronizes batch sequencing and safety interlocks across redundant controllers, ensuring no recipe deviation during switchover.

Pharmaceutical freeze dryers deploy it to maintain validated temperature profiles across primary/backup PACs, with HART data mirrored for audit continuity. From pipeline SCADA to steel caster automation, the GE IC695RMX128-DG anchors industrial automation with bulletproof redundancy that drives compliance and resilience.

- IC695RMX128-DG

- IC695RMX128-DG

- IC695RMX128-DG

IC695RMX128-CF – Earlier 128 MB revision without enhanced diagnostics

IC695RMM002 – Redund plummets CPU link module (required pair)

IC695CPE400 – Rackless CPU with built-in PROFINET (redundancy-ready)

IC695FTB001 – Fiber termination block for panel routing

IC695CHS012 – 12-slot backplane for dual-RMX layouts

IC695PSA140 – 140 W PSU for redundancy power

IC695ACC600 – Fiber optic patch cable (LC-LC, 3 m)

IC695PNS001 – PROFINET scanner for I/O redundancy

Before installing the GE IC695RMX128-DG, verify backplane power—600 mA @ 5 V per module requires dual PSUs in redundant racks; use Proficy’s load calculator. Pre-terminate fiber with LC connectors, clean with alcohol wipes, and route in separate trays from power cables. Bench-test the ring: power both RMXs, confirm SYNC LEDs go solid green within 3 seconds; inject a %R write on primary and verify backup mirror in <1 µs via logic analyzer. Set node IDs via rotary switches (0 for primary, 1 for secondary). After insertion, monitor FAULT LEDs—if flashing, check fiber continuity with an OTDR or reseat connectors.

Maintenance is diagnostics-led: weekly HMI review of %S CRC counters; log trends to predict fiber degradation. Quarterly, cycle fiber paths with a spare patch cable to verify <0.5 dB loss. In dusty plants, clean LC ports annually with a fiber scope. A persistent FAULT usually traces to fiber bend radius <30 mm—reroute before suspecting the module. This predictive, fiber-focused cadence keeps the GE IC695RMX128-DG as a silent sentinel of redundancy, ensuring failover never fails.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626