Description

| Specification | Details |

|---|---|

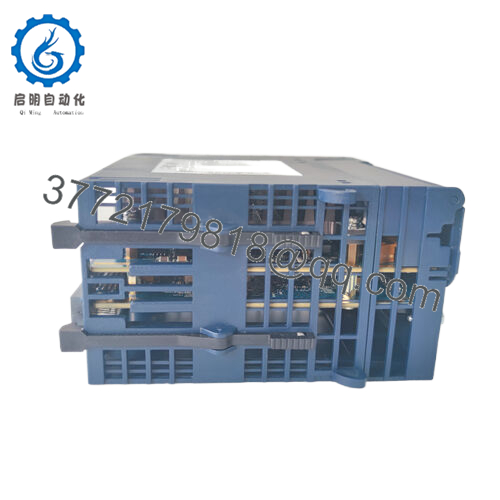

| Model Number | IC695PBS301-AA |

| Brand | GE (Emerson) |

| Type | PROFIBUS DP Slave Module |

| Input Voltage | 5 V DC (backplane) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | RX3i Universal Backplane |

| Dimensions | 5.5 x 0.7 x 3.4 in (140 x 18 x 86 mm) |

| Weight | 0.24 kg |

| Interface/Bus | Backplane / PROFIBUS DP (RS-485) |

| Compliance | CE, UL, cUL, ATEX Zone 2 |

| Supported Protocols | PROFIBUS DP-V0/V1 |

| Typical Power Draw | 400 mA @ 5 V DC |

The GE IC695PBS301-AA emerges as a pivotal PROFIBUS DP slave module for PACSystems RX3i, crafted to resolve these integration hurdles by providing a robust, configurable conduit for I/O data exchange. It’s vital in hybrid environments where master controllers orchestrate dozens of slaves—think upgrading a discrete assembly line to handle variable SKUs without network overhauls, or retrofitting chemical plants for finer granularity in I/O signal monitoring. Engineers turn to the IC695PBS301-AA when expanding rack-based systems, as it supports up to 244 input/output bytes per slave, ensuring granular control without overwhelming the bus. In automation ecosystems, it counters the “isolation gap” that isolates remote assets, delivering timestamped diagnostics to preempt failures like module faults or bus timeouts.

- IC695PBS301-AA

- IC695PBS301-AA

Envision a scenario in semiconductor fabs: rapid cycle times require sub-10ms response from position encoders, but noise from adjacent tools corrupts signals—here, the GE IC695PBS301-AA‘s galvanic isolation and auto-baud detection maintain fidelity, enabling fault-tolerant topologies that sustain high reliability amid 24/7 demands. For decision-makers assessing scalability, its hot-swappable design and GSD file compatibility streamline commissioning, slashing integration risks. Ultimately, this module fortifies process control architectures, turning fragmented networks into synchronized powerhouses that drive efficiency without the dread of mid-shift reboots.

Within the PACSystems RX3i backplane systems, the IC695PBS301-AA slots into any universal baseplate, interfacing via the rack’s high-speed bus to the CPU or network interface unit, while exposing a DB9 connector for the PROFIBUS DP segment. This placement anchors it in the I/O architecture‘s periphery, acting as a slave endpoint that polls data from field devices—limit switches, analog transmitters, or drive status—before packaging it for upstream masters like Siemens S7 or the RX3i’s own IC695PBM300.

In action, it listens for master requests over RS-485 twisted-pair, responding with configured byte blocks (up to 244 bytes each direction) while supporting sync/freeze modes for time-critical synchronization. Onboard EEPROM stores the GSD file for plug-and-play setup in master tools, and dual-channel isolation (1500V) shields against ground potentials, with auto-addressing to dodge conflicts in daisy-chained segments. Diagnostics integrate natively: status LEDs illuminate for bus activity, token pass, or errors, while fault codes propagate to the RX3i controller for HMI visualization—think alerting on overcurrent before it trips a segment. Redundancy options via ring topologies or dual slaves enhance availability, and it meshes with CIP Motion or Modbus gateways for broader connectivity.

For the deploying engineer, this means a module that configures via Proficy Machine Edition—define your process image, load the GSD, and it’s field-ready—without proprietary lock-ins. It thrives in segmented networks, offloading comms from the CPU to preserve cycles for logic execution, and handles broadcast polls efficiently in multi-drop setups up to 1200m. Whether bridging to legacy slaves or enabling predictive analytics via embedded counters, the IC695PBS301-AA embodies flexible, resilient automation that adapts to evolving topologies without forklift upgrades.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626