Description

| Specification | Details |

|---|---|

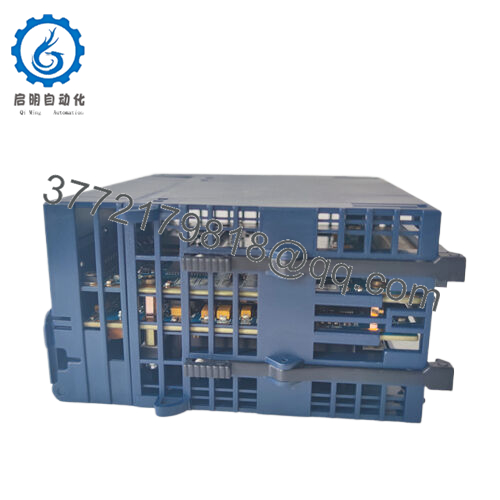

| Model Number | IC695NIU001-AD |

| Brand | GE (Emerson) |

| Type | Ethernet Network Interface Unit |

| Input Voltage | 5 V DC / 3.3 V DC (backplane) |

| Operating Temp Range | 0 to 60 °C |

| Mounting Style | RX3i Universal Backplane Slot |

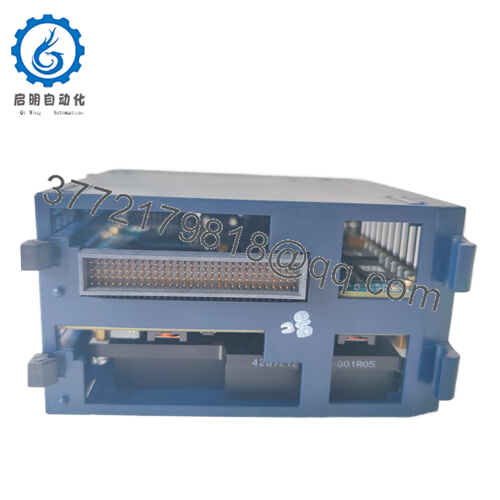

| Dimensions | 5.57 x 1.57 x 5.12 in (141.5 x 40 x 130 mm) |

| Weight | 0.75 lb (0.34 kg) |

| Interface/Bus | Dual 10/100 Mbps Ethernet, PCI |

| Compliance | CE, cULus, RoHS |

| Supported Protocols | TCP/IP, UDP, SRTP, Modbus TCP, SNMP |

| Typical Power Draw | 1.5 A @ 5 V, 0.8 A @ 3.3 V |

The GE IC695NIU001-AD, an advanced Ethernet Network Interface Unit for PACSystems RX3i, resolves this by transforming remote drops into autonomous nodes, embedding local logic and flash storage to cache data during network hiccups while bridging Series 90-30 hardware to modern Ethernet fabrics.

These challenges intensify during phased modernizations: swapping a 90-30 controller for RX3i power leaves I/O islands stranded on RS-485, demanding custom gateways that inflate engineering hours and complicate diagnostics. The GE IC695NIU001-AD intervenes precisely here, equipping remote backplanes with dual Ethernet ports for ring topologies and MRP redundancy, ensuring critical system uptime even over 100-meter cable hauls. In automation environments chasing IIoT scalability, its 20 KB local logic buffer executes fallback routines—like safe states for valve actuators—autonomously, preventing total stalls from transient outages. For engineers, this means reclaiming control: poll hundreds of points across drops without polling floods, overlay HART diagnostics via TCP, or sync trends to cloud historians seamlessly. It’s not just a connector; it’s the linchpin for hybrid resilience, letting you evolve piecemeal while upholding process control precision and slashing retrofit risks.

Deploying it unlocks granular oversight—reference tags mirror CPU memory over the network, feeding Proficy dashboards for predictive wear analysis on distant pumps. In brownfield sites, it preserves 90-30 wiring investments, accelerating ROI by months. Ultimately, the GE IC695NIU001-AD reframes remote I/O from a liability to a strength, fostering agile I/O architecture that grows with your ambitions rather than against them.

- IC695NIU001-AD

- IC695NIU001-AD

- IC695NIU001-AD

Serving as the networked nerve center in RX3i ecosystems, the GE IC695NIU001-AD elevates remote racks into intelligent outposts, interfacing via the universal backplane’s PCI lane to marshal I/O modules while projecting Ethernet connectivity to the host CPU. It claims a single slot, powering up from the rack’s 5 V/3.3 V supplies, with front-facing dual RJ-45 ports (10/100 Mbps) for daisy-chaining or redundant rings—MRP ensures <50 ms recovery on breaks. An embedded station manager handles TCP/IP, UDP, and SRTP protocols, tunneling serial data from attached 90-30 modules to the primary controller as if local, complete with timestamped refreshes to sidestep skew.

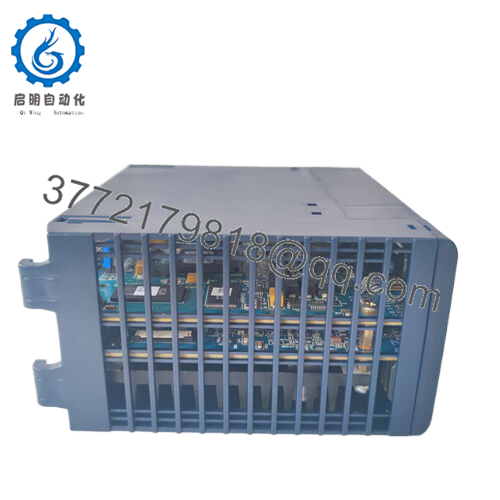

In the automation stack, it layers between field I/O and the core CPU, offloading remote scans to free rack bandwidth—up to 512 points per drop at 5 ms intervals—while 10 MB flash retains configs and logs against power loss. Local logic shines for edge decisions: 20 KB user memory runs simple ST or ladder snippets, like interlocks on conveyor faults, triggered by %I/%Q maps that sync bidirectionally over Ethernet. Diagnostics pulse through: web server exposes port stats and buffer usage via any browser, with SNMP traps for network faults escalating to SCADA. For redundancy, pair drops in hot-standby via fiber modules, mirroring states in real time to mask cable faults.

Wiring integrates fluidly—add an IC695ETM001 for twisted-pair extensions, or leverage RS-232/485 ports for legacy tie-ins—and it supports up to 16 NIUs per system, scaling to campus-wide webs without custom routing. This positions it ideally for skid-based processes or substation panels: raw inputs from remotes arrive conditioned, get locally vetted, then stream to HMIs with minimal jitter, enhancing overall process control determinism in sprawled layouts.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626