Description

Real-World Use & Application Scenarios

In modern RX3i-based automation networks, the GE IC695NIU001-AB functions as a primary Ethernet Network Interface Unit (NIU), enabling remote I/O access, distributed orchestration, and platform-wide data distribution across PACSystems RX3i architectures. This module is commonly deployed in facilities that demand reliable, scalable Ethernet-enabled integration with PACSystems controllers, such as chemical processing plants, refining operations, metal finishing, water/wastewater facilities, and large-scale manufacturing lines. Real-world challenges it helps mitigate include coordinating remote devices across long cable runs, enabling secure SCADA communications, and providing a stable bridge between local PLC networks and enterprise systems. The NIU’s capability to route and manage Ethernet-based I/O traffic supports remote diagnostics, configuration management, and asset health monitoring, all essential for minimizing downtime and optimizing plant performance. With Ethernet-based connectivity, engineers can deploy plant-wide data aggregation, real-time trending, and remote access for maintenance, ensuring visibility and control across distributed assets. In retrofit projects, the IC695NIU001-AB often serves as a bridge between legacy serial networks and modern Ethernet infrastructure, easing migration paths while preserving existing automation logic.

Product Introduction & Positioning

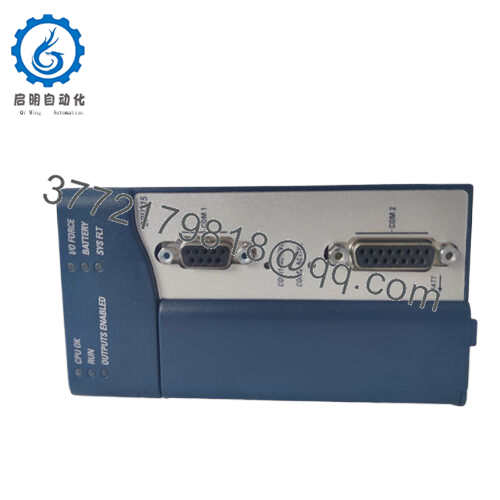

The IC695NIU001-AB is a PACSystems RX3i Ethernet Network Interface Unit designed to provide Ethernet connectivity for RX3i systems. It enables remote I/O access, rapid data exchange, and networked communication with PACSystems controllers and field devices. This module slots into RX3i backplanes and connects via Ethernet to support diagnostics, remote programming, and integrated control architectures. For engineers and integrators, the IC695NIU001-AB delivers a flexible, scalable solution to extend RX3i reach, enabling distributed control, remote monitoring, and seamless integration with IT/OT networks. Its value lies in simplifying remote access, enabling faster commissioning, and improving system resilience through reliable network interfaces within the RX3i ecosystem.

Key Technical Features & Functional Benefits

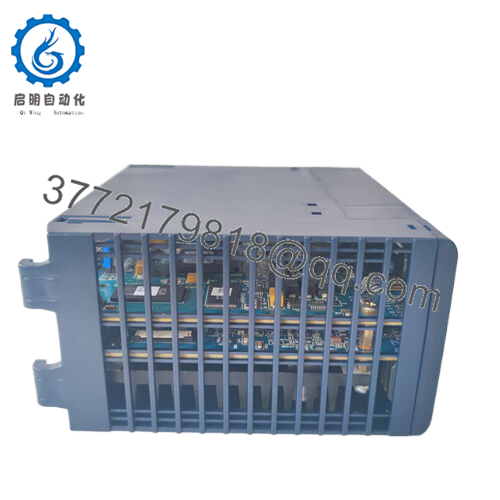

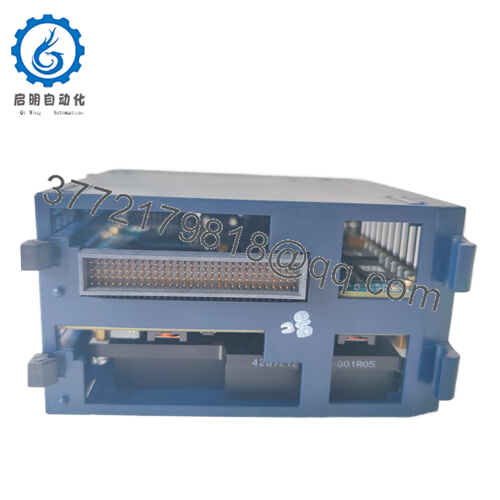

The IC695NIU001-AB offers robust Ethernet-based connectivity designed for industrial environments, with dual-port or single-port configurations depending on revision. Its primary strengths include reliable network traffic handling for PACSystems RX3i environments, straightforward integration with existing RX3i processors and I/O modules, and secure remote access capabilities for diagnostics and maintenance. The module typically supports standard industrial Ethernet features such as SNMP, device discovery, and remote configuration, helping operators maintain uptime and optimize network performance. The NIU’s design emphasizes rugged connectors, EMI resilience, and compatibility with RX3i backplanes, ensuring stable operation in manufacturing floors, process plants, and utility facilities. In practice, engineers appreciate reduced cabling complexity, clearer network segmentation, and improved visibility into remote devices, which translates into faster fault isolation and maintenance planning.

- IC695NIU001-AB

- IC695NIU001-AB

Detailed Technical Specifications

- Model: IC695NIU001-AB

- Brand: Emerson (GE Fanuc RX3i)

- Type: Ethernet Network Interface Unit

- Backplane Compatibility: RX3i backplane

- Ethernet Ports: 1–2 Ethernet ports (depending on revision)

- Protocol Support: Ethernet-based management and standard RX3i communications; SNMP and related network-management features typically present

- Power Requirements: Low-power, supplied from the RX3i ecosystem (specifics vary by revision)

- Operating Temperature: Industrial range (approx. 0°C to 60°C)

- Mounting: RX3i rack backplane environment

- Certifications: Industrial safety and EMI certifications vary by region and revision

- Diagnostics: Link status, port activity, and remote management status indicators

- Networking: Supports remote diagnostics, configuration, and data exchange within RX3i networks

Related Modules or Compatible Units

- IC695CHS012 RX3i rack for multi-module RX3i installations

- IC695ETM001 Ethernet module for extended remote diagnostics and SCADA connectivity

- IC695ALG-series I/O modules (inputs/outputs) for extended RX3i I/O capacity

- IC694TBB032 terminal blocks for field wiring in RX3i systems

- IC695CPE330 or higher-end RX3i CPUs for enhanced processing alongside NIU

- IC694UAD/IC694UD series analog/digital I/O modules for broader system integration

- IC695PNC001 PROFINET/industrial Ethernet adapters for expanded network interoperability

Installation Notes & Maintenance Best Practices

Plan the network topology to minimize hops between the NIC and RX3i controllers, ensuring proper Ethernet cable routing with strain relief and enclosure protection. Verify IP addressing and VLAN segmentation to isolate RX3i traffic, reducing broadcast load on critical control networks. Regularly review port statistics, firmware levels, and remote-management logs to detect performance degradation early. When performing firmware updates or configuration changes, follow change-control procedures and backup RX3i project data. Maintain clear labeling for Ethernet connections and document network diagrams for future expansions or audits.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626