Description

In the relentless pace of industrial automation, achieving fault-tolerant control without the drag of single-processor vulnerabilities is a persistent engineering challenge. Consider a batch processing line in pharmaceuticals where a primary CPU glitch halts sequencing, contaminating runs and triggering recalls, or a wastewater treatment cascade where redundant failover lags expose pumps to dry-running and structural failures—these scenarios highlight the fragility of non-redundant architectures, where data sync issues or scan overruns cascade into hours of downtime and regulatory scrutiny. The GE IC695CRU320-EJ emerges as a redundancy-capable central processing unit (CPU) from GE Vernova’s PACSystems RX3i family, designed to deliver hot standby redundancy for mission-critical applications, ensuring seamless logic execution and I/O signal continuity even amid hardware faults.

This CPU becomes indispensable in environments demanding unyielding availability, such as upgrading legacy Series 90-30 systems to support phased I/O migrations, or in discrete manufacturing cells where synchronized motion requires sub-second switchovers to prevent axis collisions. In a renewable energy microgrid, for example, it synchronizes inverter controls under fluctuating solar inputs, buffering scan data to maintain grid stability without the yield losses from non-redundant trips. For food and beverage fillers with hygienic enclosures prone to thermal cycling, the GE IC695CRU320-EJ leverages its battery-backed RAM for persistent program retention, upholding process control integrity without compromising on Proficy Machine Edition compatibility. It’s especially vital during expansions in high-density racks, where its two-slot footprint minimizes cabling overhead, aligning with goals of modular scalability in EMI-laden or remote outposts.

What elevates it in process control is its emphasis on operational resilience: with firmware at revision 7.15, it supports up to 64 MB user memory for complex ladder logic, adapting to diverse I/O via serial backplane without full redesigns. In vibration-intense sites or dust-choked panels, its solid-state build isolates noise, while SNP slave protocol enables straightforward HMI polling. For teams bridging old and new PACSystems, the GE IC695CRU320-EJ fortifies upgrades, reusing expansion modules to defer capex, transforming redundancy from a luxury to a baseline for sustained efficiency in industrial automation where every scan cycle counts.

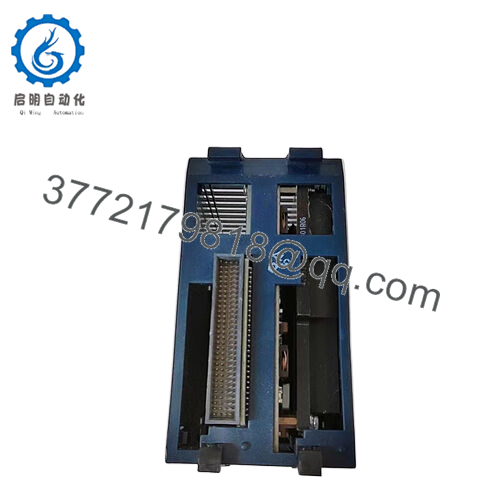

When incorporating the GE IC695CRU320-EJ into your PACSystems ecosystem, view it as the vigilant duplicate brain for RX3i racks, where it mirrors primary logic execution on its 1 GHz Celeron M processor, arbitrating data sync over the backplane for bumpless failover in under one logic scan (minimum 3.133 ms). This CPU occupies two slots in the main rack, interfacing via the serial backplane for up to 512 I/O points or remote drops, positioning it mid-stack—above field devices but below supervisory SCADA layers—while dual Ethernet ports (via add-on modules) enable Profinet or Modbus extensions for HMI integration. In TMR-like setups, it pairs with a secondary unit for hot standby, where heartbeat signals trigger automatic switchover without process interruption, ideal for high-availability loops in distributed control.

Interaction flows through Proficy Machine Edition for programming, supporting ladder, function block, or structured text for real-time tasks like PID tuning or data logging, with 64 MB flash for non-volatile storage against power loss. Diagnostics shine via front LEDs for run/fault status and USB/serial ports for log pulls, feeding directly into CIMPLICITY for trend analysis—crucial in process control where remote access trumps on-site diagnostics. Without built-in redundancy beyond standby pairing, it scales via RX3i expansion racks (up to 7 remote), maintaining galvanic isolation to shield upstream logic from field noise, while firmware hooks allow online upgrades without halting scans.

This modularity extends to hybrid environments: daisy-chain it with IC695 modules for denser I/O in large-scale processes, configure via Ethernet for custom scan rates, and test failover with built-in simulations to verify against overruns. For backplane users familiar with Series 90-30, the GE IC695CRU320-EJ feels intuitive, elevating standalone controllers into resilient duplicates that adapt to evolving demands, from single-line expansions to plant-wide synchronization.

| Specification | Details |

|---|---|

| Model Number | IC695CRU320-EJ |

| Brand | GE Vernova |

| Type | Redundancy CPU (PACSystems RX3i) |

| Input Voltage | 3.3 VDC (1 A), 5 VDC (1.2 A) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Rack (Two Slots) |

| Dimensions | 14.7 x 5.1 x 3.4 cm |

| Weight | 0.5 kg |

| Interface/Bus | Serial Backplane, USB, Ethernet (via module) |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Proficy Machine Edition, SNP Slave |

| Typical Power Draw | 10 W |

Deploying the GE IC695CRU320-EJ instills computational symmetry that defies single-point perils, its hot standby mirroring—switching in under one scan—preserving logic continuity to avert the 3-5% yield hits from non-redundant faults in continuous processes, while 64 MB RAM buffers complex datasets for tighter loop control without the overruns that plague under-specced CPUs. This reliability cascades into maintenance efficiency, as battery-backed retention safeguards against power glitches, enabling quick restores in brownout-prone sites and cutting recovery from hours to minutes via Proficy uploads.

The integration value amplifies through RX3i heritage, where it reuses Series 90-30 I/O for hybrid migrations, slashing engineering hours by repurposing existing drops and configs—deployments that once took weeks now align in days. For consistency, its Celeron core executes at 1 GHz without thermal throttling up to 60°C, ensuring scan rates hold firm in enclosed cabinets, while firmware 7.15 adds security patches for networked ops, deferring upgrades and easing cybersecurity audits. Engineered for grit in humid or particulate bays, it sustains memory integrity over cycles, postponing battery swaps and meshing with opex cycles in regulated sectors.

- IC695CRU320-EJ

- IC695CRU320-EJ

Forward, this CPU trims holistic costs by optimizing power at 10 W, lightening rack thermals and UPS demands for greener footprints, while expandable flash defers storage refreshes for agile systems that evolve with I/O creep. In high-reliability domains, the GE IC695CRU320-EJ acts as a safeguard multiplier, weaving standby logic into frameworks that weather transients, ensuring your industrial automation pulses with resilient precision.

In power distribution substations, the GE IC695CRU320-EJ duplicates breaker logic via hot standby, buffering scan data amid voltage swings to guarantee critical system uptime in process control environments where failover averts blackout cascades. Its high-reliability backplane processes I/O signals from relays, ensuring sequence fidelity.

Food processing lines leverage it for filler synchronization, mirroring motion commands under sanitary washes—delivering redundancy schemes that uphold signal purity and continuous throughput in cleanroom bays. In chemical reactors, it governs batch recipes against feed variances in corrosive vaults, supporting modular drop expansions. These integrations position the GE IC695CRU320-EJ as a redundancy rock in rugged, scan-sensitive industrial automation, where CPU duality meets endurance.

IC695CRU320-EN – Earlier firmware variant for legacy Series 90-30 migrations with basic redundancy.

IC695CRU320-EK – Upgraded model with enhanced security for networked high-availability setups.

IC695CRU320-EH – Cost-optimized non-redundancy alternative for standalone RX3i applications.

IC695CPU315 – High-end single CPU for non-redundant high-throughput logic.

IC695ACC302 – Smart battery companion for extended RAM retention in remote sites.

IC693ACC302 – Auxiliary battery add-on for legacy I/O compatibility.

IC695PNC001 – PROFINET scanner module for Ethernet I/O expansions.

IC690RBT001 – Rechargeable battery for portable rack configurations.

Prior to rack-mounting the GE IC695CRU320-EJ, cross-check backplane seating—the two-slot design demands firm edge alignment to prevent intermittent contacts, and verify jumper settings if blending with Series 90-30 drops to avoid scan mismatches. Assess 3.3/5 VDC rails for clean delivery under full load, as ripple over 5% can jitter clocks; add regulators if PSU noise from adjacent modules intrudes. Ensure firmware 7.15 via Proficy upload matches your primary unit, as version drifts throttle sync handshakes.

Post-install, ongoing care revolves around straightforward vigilance that integrates with routines. Fortnightly, monitor front LEDs for run/sync status—steady greens affirm pairing, but flashing faults signal a log extraction via USB to pinpoint overruns. Every six months, reseat the battery for retention checks and execute a self-test COMMREQ to baseline scan times against drifts, confirming switchover under 3 ms. In dusty or humid enclosures, a quarterly connector inspection with isopropyl wipes guards against oxidation, coupled with torque verifications on mounting screws to resist vibration. These measures, grounded in GE’s RX3i guide, prioritize sustainability over constant oversight, keeping the GE IC695CRU320-EJ as a dependable sentinel in your PACSystems lineup.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626