Description

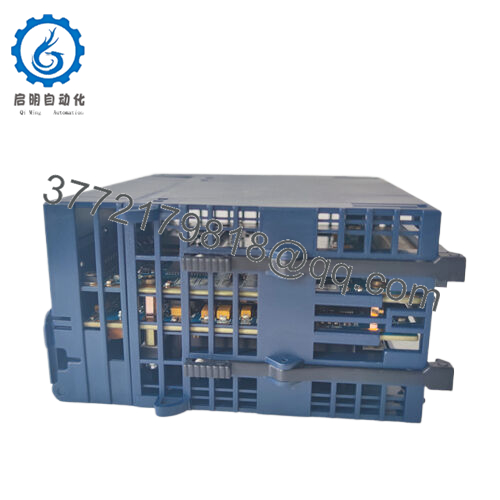

IC695CPU315 Product Description:

GE IC695CPU315 is GE VersaMax ™ The high-performance CPU module of the automation platform is known for its flexibility and open architecture. As the core of the VersaMax ecosystem, it executes control logic, manages I/O operations, and facilitates communication with field devices, drivers, and monitoring systems in accordance with the IEC 61131-3 standard.

IC695CPU315

TheIC695CPU315adopts a 300 MHz ARM processor and 256 MB user memory (expandable to 512 MB via SD card), achieving a balance between processing speed (ladder logic scan time of 0.5 milliseconds/kilobyte) and cost-effectiveness, making it suitable for a wide range of applications from standalone devices to distributed control systems (DCS). Its compatibility with Studio 5000 Logix Designer software simplifies programming for ladder diagrams, structured text, or functional block diagrams, while support for Modbus RTU and Ethernet/IP ensures seamless integration with third-party devices such as VFDs or smart sensors.

Its compact design (width of 100mm) and DIN rail installation method optimize the space utilization inside the control cabinet. For integrators, IC695CPU315 serves as a bridge between traditional RS-232/485 systems and modern Ethernet networks, supporting phased upgrades without the need for comprehensive infrastructure upgrades.

IC695CPU315

Main features and advantages:

Processing and memory performance

The 300 MHz processor provides reliable scan time for moderately complex applications, such as managing up to 1000 ladder steps or executing PID control loops for temperature or pressure regulation. With 256 MB of user memory (expandable via SD card), it can store programs, trend data, and recipes, eliminating the need for an external data logger in simple settings.

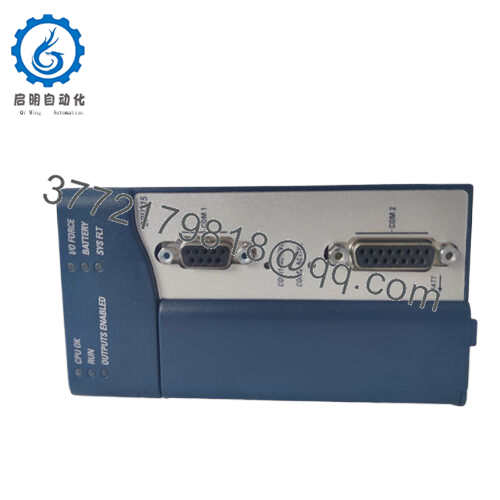

Communication flexibility

This CPU is equipped with built-in RS-232/485 ports and optional Ethernet/IP module (IC695ETM001), supporting protocols such as Modbus RTU, DF1, and Ethernet/IP, and can be connected to SCADA systems, HMI (such as GE’s iFIX), and cloud platforms through MQTT gateway. This flexibility supports remote monitoring of key indicators such as overall equipment efficiency (OEE) or energy consumption, thereby supporting predictive maintenance strategies.

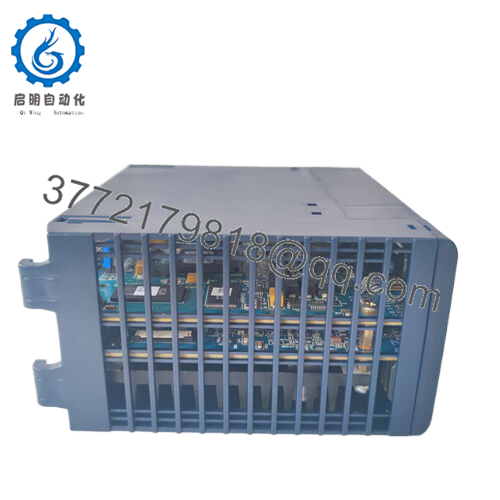

Robust industrial design

The working temperature range of IC695CPU315 is -20 ° C to+60 ° C, which complies with the IEC 61000-6-2/6-4 electromagnetic compatibility standard and can withstand dust, moisture, and electromagnetic interference in industrial environments. Its fanless design reduces maintenance requirements, while diagnostic LED indicators (power, operation, fault, communication) provide clear updates on status. The hot swappable design of this module allows for on-site replacement without shutting down the system, thereby minimizing downtime during maintenance.

Scalability and redundancy

IC695CPU315 supports connecting up to 8 local I/O racks and 32 remote I/O nodes through the VersaMax remote I/O protocol, and can be expanded from 256 to 4096 I/O points according to project requirements. Although it does not support hot standby redundancy itself, it can be paired with auxiliary CPUs for non critical applications in cold standby configurations and use external relay logic for fault transfer.

IC695CPU315

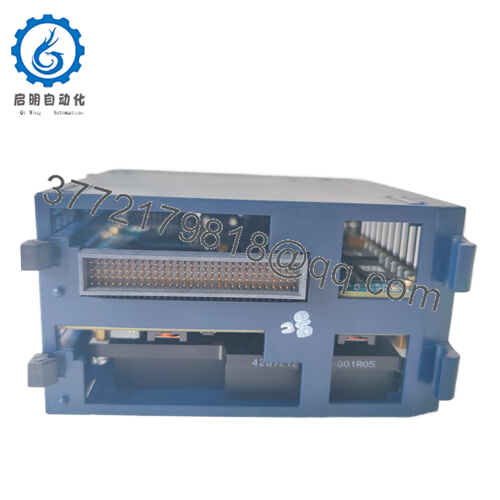

Technical specifications:

Model IC695CPU315

Brand GE

Type PLC CPU module (VersaMax) ™)

Processor 300 MHz ARM

User memory 256 MB (expandable to 512 MB via SD card)

Power supply 24 VDC (input range 10-30 VDC)

Working temperature -20 ° C to+60 ° C

Installation method DIN rail (EN 50022)

Size 100 x 150 x 110 millimeters (width x height x depth)

Weight 0.8 kilograms

Local communication RS-232/485 (Modbus RTU, DF1)

I/O supports up to 4096 points (local+remote)

Programming Studio 5000 Logix Designer (IEC 61131-3 language)

Certification CE, UL, cUL, CSA

Expansion slot 1 (for Ethernet/IP or serial modules)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp: 16626708626

Email: 3772179818@qq.com

IC695CPU315

Application areas:

On food and beverage production lines, IC695CPU315 can manage conveyor systems, sterilization rooms, and packaging machinery, ensuring precise coordination of sensors, actuators, and human-machine interfaces (HMI). Its ability to support up to 4096 I/O points (with remote I/O support) makes it an ideal choice for managing multi-stage production processes such as filling lines or meat processing facilities, where compliance with hygiene standards and production speed are crucial. In water treatment plants, the CPU controls the pump group network, monitors water quality parameters, and performs automatic chemical dosing to adapt to constantly changing inflow rates while maintaining regulatory compliance.

IC695CPU315

Related products:

IC695MDL740-32 point digital input module (24 VDC), suitable for high-density sensor integration.

IC695MDL752-16 point digital output module (24 VDC, relay), suitable for driving inductive loads.

IC695ALG223-8-channel analog input module (12 bits, 4-20 mA), suitable for process variable monitoring.

IC695ETM001- Ethernet/IP module, used to connect to industrial networks and SCADA systems.

IC695PWR321- Single power module (24 VDC), suitable for non redundant settings.

IC695CMM301- Serial Communication Module (RS-485), suitable for Modbus RTU or Profibus DP devices.

IC695ACC301- High speed counter module (50 kHz), suitable for motion control in packaging applications.

IC695CPU315

Installation and maintenance:

Precautions before installation

Before installing IC695CPU315, please ensure that the control cabinet has sufficient ventilation to maintain the ambient temperature below 50 ° C. Use a dedicated grounding conductor (≥ 4 mm ²) to ground the chassis to reduce electromagnetic interference (EMI), especially when close to high-power equipment such as frequency converters. When configuring remote I/O, please verify the cable length and terminal resistance to maintain signal integrity.

maintenance agreement

Perform visual inspections monthly to check for loose terminal blocks or signs of corrosion. Use Studio 5000 to view CPU diagnostic information, including memory usage and communication error rates, and back up programs to SD cards or network drives every quarter. If equipped with an internal battery, please replace it every 5 years to preserve real-time clock and memory data. For systems with remote I/O, please test network connectivity annually by simulating cable failures and verifying recovery. Record all maintenance activities to comply with ISO 9001 requirements.

Other GE brand product models:

GE 469-P5-HI-A20-E-H

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

GE 5266222-2 – GSCB GOC6.6

GE IS400AEBMH1AJD

GE DS200TCQCG1AJD

GE 239-RTD-AN

GE 239-RTD-AN

GE 239-RTD-AN

GE 269PLUS-100P-120VAC

GE IS420UCSBH1A

GE Physical 239 239-RTD-AN

GE VMIVME2540-300

GE 8507-BI-DP 8507-BI-DP-01

GE VMIVME2540

GE SLN042 IC086SLN042-A

GE SLN080 IC086SLN080-A

GE VMIACC-5595-208 350-805595-208N

GE SBC486DX66

GE F650 F650BFBF2G0HIE

GE VMIACC-5595-208

GE IS215WEPAH2B

GE IS210AEAAH2B

GE 239

GE 369 panel

GE IS210AEBIH3B

GE IC660EPM100J

GE VPROH2B IS215VPROH2BC

GE DS2020PDMAG6

GE IS220UCSAH1A

GE DS200TCQCG1AJD

GE IS200ECTBG1ADE

GE IS200EXHSG3REC

GE IS220PPDAH1A

GE 845-EP5M5G5HNNAANGAPBCSENWB

GE 336A5199AMP1

GE F35-C-U03-HUH-F8L-H67-M6T-PXX-UXX-WXX

GE C60-C-U03-HUH-F8L-H6U-M6D-P6D-U6T-WXX

GE HE700GEN200

GE IC697BEM763

GE 339-E-P1-G1-H-E-S-N-P-1E-D-N

GE DS3800NB1B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626