Description

Real-World Use & Application Scenarios

In modern plant automation, the GE IC695CPE330 serves as a central PACSystems RX3i CPU with dual-core processing, designed to orchestrate complex control tasks across multiple I/O modules and subsystems. This CPU enables high-throughput sequencing, fast decision-making, and reliable network communications in process industries, batch facilities, and continuous manufacturing lines. Typical use cases involve coordinating distributed control logic, managing advanced control loops, and handling diagnostic data across Ethernet-enabled networks. The CPE330’s dual Ethernet interfaces and robust onboard memory support scalable architectures, enabling operators to run sizable control programs, execute remote diagnostics, and maintain tight synchronization with other RX3i components. The CPU’s architecture supports fault-tolerant configurations, hot-swappable replacement, and straightforward integration with legacy GE-Fanuc RX3i I/O families, making it a solid choice for both new builds and retrofit projects. In facilities emphasizing uptime, the CPU’s performance and networking capabilities help reduce cycle times, improve throughput, and enable richer data sharing across the control network.

Product Introduction & Positioning

The IC695CPE330 is a PACSystems RX3i CPU module featuring a 1 GHz dual-core processor, 64 MB of built-in program memory, and dual independent Ethernet interfaces. This controller is designed to sit at the heart of a PACSystems RX3i control system, coordinating logic, data exchange, and inter-module communications. Its backplane form factor fits standard RX3i racks, allowing seamless integration with I/O modules, memory exchange modules, and remote diagnostics hardware. For engineers and integrators, the IC695CPE330 delivers a potent blend of processing power, network versatility, and straightforward software tooling. It supports robust real-time control, supports multiple communication protocols, and provides a solid upgrade path for expanding RX3i deployments while preserving compatibility with existing field devices and configuration methodologies.

Key Technical Features & Functional Benefits

A core strength of the IC695CPE330 is its 1 GHz dual-core processing capability, which translates to faster program execution, more responsive control loops, and smoother handling of complex automation routines. With 64 MB of built-in program memory and 64 MB of non-volatile memory, the CPU supports sizable control strategies, substantial recipe handling, and persistent data storage for long-running operations. The two Ethernet interfaces enable versatile network topologies, including redundant or segmented networks, facilitating reliable remote access, diagnostics, and field device integration. Its backplane compatibility ensures seamless interaction with RX3i I/O modules, memory exchange devices, and other RX3i CPUs, enabling scalable, modular architectures. The IC695CPE330 also supports standard RX3i software tools and engineering environments, which simplifies commissioning, testing, and ongoing maintenance. In terms of reliability, GE/Emerson’s RX3i CPUs are designed for industrial environments with rugged connectors, fault-tolerant options, and a broad array of accessories, supporting long service life in demanding plants.

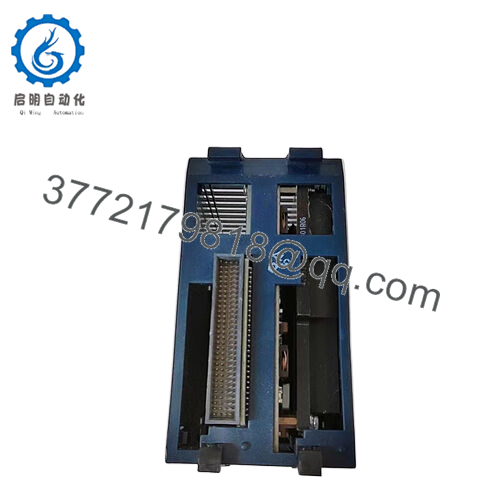

- IC695CPE330

- IC695CPE330

Detailed Technical Specifications

- Model: IC695CPE330

- Brand: Emerson (GE Fanuc RX3i)

- Type: PACSystems RX3i CPU

- CPU Features: 1 GHz dual-core processor

- User Memory: 64 MB built-in

- Non-Volatile Memory: 64 MB

- I/O Capacity: Supports large RX3i I/O configurations (discrete and analog)

- Ethernet Interfaces: Two independent 10/100/1000 Mbps Ethernet ports

- Communication Protocols: Ethernet-based protocols plus standard RX3i backplane communications

- Backplane: Universal RX3i backplane

- Operating Temperature: Industrial range (typical 0°C to 60°C)

- Power Requirements: DC power compatible with RX3i systems (specific values vary by revision)

- Mounting: RX3i rack backplane; requires compatible housing and rack

- Certifications: Industrial certifications consistent with RX3i components (region-dependent)

- Firmware: Supports RX3i firmware families and PME-based configuration

- Redundancy: Optional hot-standby or redundant Ethernet/network configurations

Related Modules or Compatible Units

- IC695CHS012 RX3i rack for multi-module installations

- IC695ETM001 Ethernet module for remote diagnostics and SCADA connectivity

- IC695CPE330 pairs with memory and I/O expansion modules like IC695ALG-series inputs/outputs

- IC694TBB032 terminal blocks for field wiring in RX3i systems

- IC695PNC001 PROFINET controller modules for integrated industrial Ethernet networks

- IC695CPE430 or other RX3i CPUs for higher-end processing and expanded features

- IC694UAD or other analog/digital I/O modules used with RX3i

- IC695ACC402 Energy Pack for extended runtime in transient power conditions

Installation Notes & Maintenance Best Practices

Plan the RX3i rack layout to ensure adequate cooling and clearance around the IC695CPE330, particularly in cabinets with dense I/O and multiple line-powered devices. When wiring, follow disciplined cable management and grounding practices to minimize EMI on the Ethernet ports and ensure reliable communication with peripheral devices. During commissioning, validate the boot sequence, verify memory integrity, and map program memory blocks to the control strategy. Regular firmware updates and PME project backups are recommended to keep the system current, with change-control records maintained for audits. For maintenance, monitor Ethernet link health, verify that the CPU retains synchronization with partner modules, and test hot-standby configurations if deployed.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626