Description

In industrial automation, where processing power and connectivity directly influence cycle times and data throughput in complex systems, balancing performance with cost-effective scaling is a constant challenge. You’re probably managing setups like multi-rack PACSystems RX3i configurations in a food and beverage plant, where delayed logic execution could disrupt recipe changes or packaging synchronization, or in automotive assembly lines requiring tight integration with vision systems and robots without overwhelming the budget for oversized controllers. The GE IC695CPE305-AF tackles this as a compact yet capable CPU module optimized for mid-range applications, delivering 1.1 GHz processing in a single-slot form factor to ensure responsive control without the overhead of higher-end units.

This module becomes critical in scenarios demanding reliable Ethernet connectivity and serial communications alongside efficient memory management, such as upgrading from legacy Series 90-30 systems to modern RX3i platforms while preserving I/O investments. Engineers rely on the GE IC695CPE305-AF when expanding distributed process control environments, where embedded switches support daisy-chaining without extra hardware, or in setups needing quick programmer access via USB for on-site tweaks. It addresses system stability by providing battery-backed retention and Energy Pack compatibility for graceful power-downs, preventing data loss in volatile power scenarios common in remote utilities. In high-reliability industrial automation, its role in handling up to 32K discrete I/O points supports modular growth, incorporating diagnostics that minimize downtime through LED feedback and fault logging. Whether contending with network congestion in PROFINET-heavy lines or ensuring protocol flexibility for Modbus integrations, the GE IC695CPE305-AF focuses on practical signal reliability and integration ease, embedding SEO elements like PACSystems RX3i CPU, embedded Ethernet interface, and process control performance for real-world deployments.

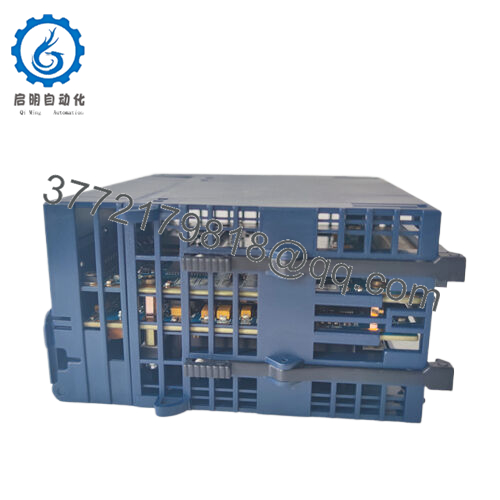

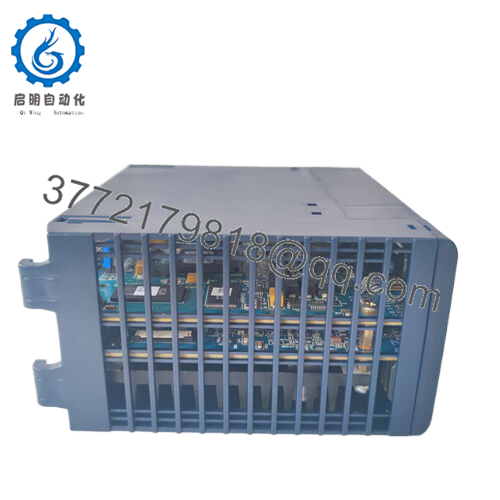

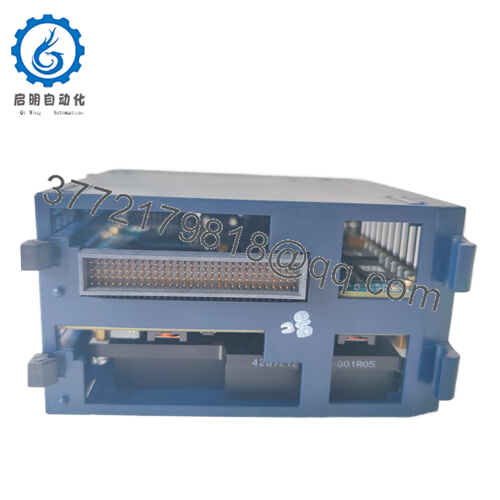

Dropping the GE IC695CPE305-AF into an RX3i universal backplane positions it as the core executor in your automation hierarchy, running user logic at sub-millisecond speeds while bridging field devices to supervisory layers. It occupies a single slot—typically paired for expansion—and interfaces via PCI bus for high-speed local I/O, plus an embedded Ethernet switch with two RJ-45 ports for 10/100 Mbps connections, enabling direct ties to HMIs, SCADA, or additional racks without discrete NICs.

In the stack, it sits atop the I/O architecture, communicating with modules like ALG or MDL series for analog/digital signals, and supports add-on cards for PROFIBUS or Genius networks. The CPU handles protocols natively: SRTP for programmer links, Modbus TCP client/server for third-party gear, and EGD for peer-to-peer data exchange—crucial in synchronized multi-controller setups. Diagnostics integrate seamlessly, with onboard LEDs for port status and faults, plus software tools in Proficy Machine Edition for deeper scans, allowing predictive fixes without halting operations. For redundancy, pair it with Media Redundancy Protocol via PROFINET controllers, though it’s non-hot-standby native; instead, it excels in standalone or primary roles with Energy Pack backup preserving RAM during outages. Serial ports—one RS-232 for firmware loads—complement Ethernet for legacy device hooks, keeping interactions straightforward. This fit streamlines process control by reducing latency in data cycles, whether routing channels for OPC UA or syncing with remote I/O over fiber extenders—the GE IC695CPE305-AF adapts to your backplane without forcing architecture overhauls.

| Specification | Details |

|---|---|

| Model Number | IC695CPE305-AF |

| Brand | GE (Emerson) |

| Type | PACSystems RX3i CPU Module |

| Input Voltage | 5 VDC @ 1A, 3.3 VDC @ 1A, 24 VDC @ 0.5A |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | RX3i Universal Backplane (single slot) |

| Dimensions | Approx. 140 x 130 x 45 mm |

| Weight | 0.45 kg |

| Interface/Bus | PCI, Embedded Ethernet (2-port switch) |

| Compliance | CE, UL, RoHS, ATEX Zone 2 |

| Supported Protocols | SRTP, Modbus TCP, EGD, PROFINET, Modbus RTU Slave |

| Typical Power Draw | 10 W |

Selecting the GE IC695CPE305-AF brings engineered efficiency to your control layer, where its 1.1 GHz core and 5 MB user memory handle complex logic without the thermal or power penalties of dual-core alternatives, ensuring consistent scan times that keep PID loops tight and motion sequences precise. This performance reliability means fewer overruns in high-I/O counts, directly translating to smoother production flows and less scrap from timing drifts.

Integration ease stands out too: the built-in Ethernet switch cuts cabling needs, while USB portability speeds application transfers, reducing engineering overhead during commissioning or updates—no more hunting for serial adapters in the field. Maintenance becomes proactive with comprehensive diagnostics accessible remotely, flagging memory corruption or port faults early to avoid cascading issues. Engineered for long-term performance in vibrating or dusty settings, its robust design and Energy Pack option ensure data integrity across power cycles, extending system uptime without constant battery swaps. Overall, it delivers value through balanced capability—high availability features like MRP support without premium pricing—letting you scale process control confidently as demands grow.

The GE IC695CPE305-AF shines in applications prioritizing connectivity and responsiveness in constrained spaces, such as water/wastewater plants using it for pump sequencing and level monitoring over PROFINET networks, where embedded ports enable ring topologies for fault-tolerant communication amid harsh, wet conditions requiring continuous uptime. In pharmaceutical environments, it’s deployed for batch control with precise timing for mixing and filling, leveraging fast Boolean execution to meet validation standards in cleanrooms with limited rack real estate.

Manufacturing lines in consumer goods often feature it driving conveyor systems integrated with vision inspection, handling rapid data cycles from sensors while Modbus links tie in legacy scales—its diagnostics support quick isolation of network drops in 24/7 operations. Across these process control environments, the GE IC695CPE305-AF provides the backbone for critical system uptime in power distribution substations or food processing, excelling under EMI stress or temperature swings with modular I/O expansion.

- IC695CPE305-AF

- IC695CPE305-AF

IC695CPE310-AF – Higher memory (10 MB) variant for logic-intensive applications IC695CPE302-AF – Entry-level sibling with reduced memory for basic control tasks IC695CPE330-AA – Dual-core powerhouse for ultra-high-performance needs IC695CPU310 – Legacy non-embedded Ethernet predecessor for direct swaps IC695CPE400 – Standalone AML-based alternative with advanced Linux co-processing IC695ACC400 – Companion Energy Pack for RAM retention during outages IC695ETM001 – Add-on Ethernet module for extra ports in dense networks IC695PNC001 – PROFINET controller for distributed I/O redundancy

Ahead of installing the GE IC695CPE305-AF, power down the rack and confirm slot compatibility—universal backplanes only, avoiding the two highest-numbered slots to prevent bus conflicts. Match firmware with your Proficy version via the release notes, as mismatches can lock out configurations; also attach the Energy Pack beforehand if using one, routing the cable cleanly to avoid pin bends. Verify grounding paths for Ethernet shielding, especially in high-noise areas, and note the RTC battery location for pre-checks—weak cells cause clock drifts on boot.

Maintenance stays practical: weekly LED reviews catch Ethernet link losses or faults promptly, while monthly serial port wipes prevent dust buildup in panel doors. Quarterly, initiate a controlled power cycle with Energy Pack to test retention, and annually update firmware through the RS-232 port if isolated from the network. For deeper health, pull logs via USB during downtime windows, spotting trends in scan overruns or memory usage. These steps keep the CPU responsive, addressing wear on flash or connectors early in demanding cycles.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626