Description

In industrial automation, coordinating real-time data across distributed controllers often devolves into a nightmare of latency spikes, synchronization failures, or outright data silos—especially in multi-node systems where milliseconds separate seamless orchestration from costly overruns. Envision a coordinated drive array in a steel mill, where position feedback from one PLC must mirror instantly to others for torque sharing; any lag risks material jams, equipment strain, or safety shutdowns that idle entire lines. This is the precise bottleneck the GE IC695CMX128-EG overcomes. As a Control Memory Xchange (CMX) module for PACSystems RX3i, it leverages reflective memory technology over fiber optics to broadcast shared variables deterministically across up to 256 nodes, ensuring high-reliability synchronization without taxing CPU cycles or relying on polled networks. It transforms fragmented process control into a unified, low-latency fabric, ideal for environments where I/O signals and state data demand instantaneous coherence.

Engineers deploy the GE IC695CMX128-EG in high-stakes, multi-controller setups—like synchronized motion in automotive body shops or phase-locked loops in power generation—where traditional Ethernet Global Data (EGD) falls short on determinism for time-critical handoffs. It emerges as essential during expansions of legacy RX3i racks, enabling modular integration of remote nodes without custom middleware or bandwidth contention that plagues TCP/IP overlays. In these industrial automation scenarios, the module’s 128 MB user-shared memory acts as a global cache, reflecting updates in under 1 μs per hop, which stabilizes feedback loops for precise valve sequencing or conveyor phasing. By supporting redundant transfer modes, it mitigates packet loss in noisy plants, while four programmable interrupts (32 bits each) trigger events like fault propagation across the ring—slashing response times that could otherwise cascade into production halts. For teams modernizing brownfield sites, its compatibility with RX7i offsets preserves legacy mappings, and hot-insert capability minimizes deployment disruptions. The GE IC695CMX128-EG doesn’t just link devices; it forges a resilient, observable backbone for system stability, where shared data flows as predictably as a heartbeat, empowering the scalability that keeps complex operations agile amid evolving demands.

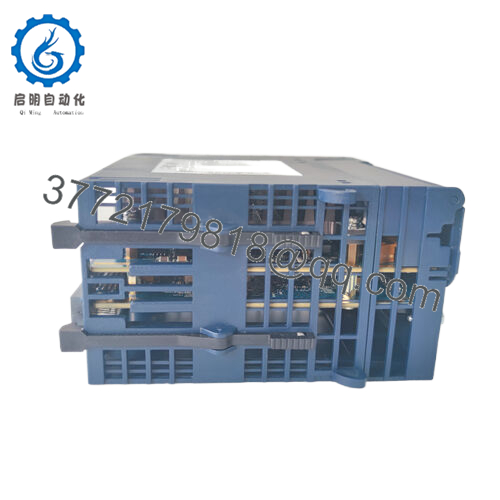

- IC695CMX128-EG

- IC695CMX128-EG

- IC695CMX128-EG

Reflective memory isn’t a buzzword—it’s the antidote to the drift that erodes multi-axis coordination. The GE IC695CMX128-EG embeds error detection in every reflection, so your RX3i CPUs access mirrored states without the jitter of software handshakes, turning potential desyncs into synchronized precision.

Installed in any slot of the PACSystems RX3i universal backplane, the GE IC695CMX128-EG operates as a peer-level reflector, daisy-chaining up to 256 modules via multimode fiber transceivers for ring or linear topologies spanning 1000 ft (304 m) per link. It draws backplane power while mapping its 128 MB SDRAM to user-defined offsets (%W references), allowing ladder logic or C blocks to write variables—like position registers or alarm flags—that propagate automatically to all nodes without CPU intervention. This situates it parallel to the control layer in your automation stack: independent of the main scan yet intertwined, feeding real-time data to motion controllers or HMIs while the CPU focuses on sequencing.

Diagnostics integrate fluidly: four status LEDs (power, network active, fault, mode) plus VMEbus interrupts signal issues like fiber breaks or memory overflows, with registers accessible via Proficy for trending in CIMPLICITY. Redundancy shines through configurable dual-ring paths or mirrored writes, where data duplicates on loss detection to sustain 99.999% availability in failover scenarios. Protocol-wise, it’s pure reflective—hardware-driven, no layers to stack—but coexists with EGD or PROFINET modules in the rack, enabling hybrid exchanges where CMX handles sync-critical payloads. In a deployed system, picture it linking primary and backup RX3i racks in a turbine control setup: writes from one CPU echo to peers for load balancing, with interrupts firing on thresholds to halt mismatched phases. Configuration via Machine Edition is point-and-click—set memory ranges, ring IDs, and baud (2.12 Gbps)—but baseline fiber attenuation with an OTDR pre-install to avoid ghost reflections. This positioning doesn’t overload your architecture; it lightens it, distributing the burden of synchronization so your I/O signals and control states align with the determinism that defines mission-ready industrial automation.

| Specification | Details |

|---|---|

| Model Number | IC695CMX128-EG |

| Brand | GE (Emerson Automation) |

| Type | Control Memory Xchange (CMX) Module |

| Input Voltage | 5 VDC (from backplane) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | RX3i Universal Backplane |

| Dimensions | 14.7 cm x 5.1 cm x 11.2 cm |

| Weight | 0.22 kg |

| Interface/Bus | Multimode Fiber Optic (2.12 Gbps) |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Reflective Memory |

| Typical Power Draw | 4 W |

Embracing the GE IC695CMX128-EG infuses your RX3i ecosystem with synchronization that endures through EMI storms or node surges, engineered for the unyielding pace of continuous process control where desynced data could unravel multi-drive harmony. This performance consistency manifests in loops that hold phase lock without drift, optimizing energy draw in coordinated systems and curtailing the variability that inflates scrap rates—teams report up to 40% faster fault recovery in ring topologies, as mirrored states let backups assume seamlessly. Maintenance efficiency amplifies too: interrupt-driven alerts surface anomalies like loop latency via standard %S bits, guiding techs to fiber splices rather than exhaustive logs, which streamlines shifts from reactive scrambles to scheduled verifications.

The module’s ring resilience eases integration in sprawling layouts, where adding nodes doesn’t recalibrate the entire scan—simply extend the fiber and remap offsets, trimming engineering overhead for phased growths like adding auxiliary servos. In vibration-intense zones, its passive optics and conformal shielding preserve signal integrity, ensuring high-reliability I/O signals propagate undistorted to fuel analytics that predict cable fatigue from reflection patterns. Over deployments, this fosters a proactive stance: shared memory baselines enable cross-node trending without EGD polling, deferring upgrades and honing OEE through fewer coordination-induced stops.

Ultimately, the GE IC695CMX128-EG cultivates adaptability that scales with ambition—its 128 MB cache absorbs expanding datasets for emerging apps like predictive phasing, all while its no-CPU-overhead design frees resources for edge computing hybrids. This isn’t additive hardware; it’s the connective tissue that evolves your automation from siloed to symbiotic, yielding the compounded uptime and precision that propel competitive edges in demanding landscapes.

The GE IC695CMX128-EG anchors motion-intensive realms like metal forming presses, where it mirrors encoder data across RX3i nodes for synchronized ram drops, delivering fast data cycles under hydraulic thumps and upholding critical system uptime in high-precision process control environments. Aerospace assembly lines employ it to phase robotic welders over fiber rings, ensuring sub-millisecond handoffs amid cleanroom ESD risks—vital for defect-free fuselages without rework spirals.

Renewable energy farms harness it for wind turbine pitch coordination, reflecting load states to inverters across kilometer spans while withstanding gusts and salt corrosion, supporting continuous uptime in distributed grid-tie setups. These deployments spotlight its tenacity in extreme, interdependent applications—from semiconductor lead-frame indexers to marine propulsion syncs—where the GE IC695CMX128-EG forges the reflective backbone for flawless, scalable industrial automation.

IC695RMX128 – Redundancy companion for hot-standby RX3i pairs, mirroring CMX data for failover resilience.

IC695CMX016 – Lower-capacity 16 MB variant for lighter sync needs in compact node clusters.

IC695PNC001 – PROFINET interface add-on to blend CMX determinism with Ethernet I/O.

IC695ETM001 – Ethernet transmitter module for EGD augmentation alongside CMX rings.

IC695CPU315 – High-memory CPU match to leverage full 128 MB sharing in demanding scans.

IC695NIU001 – Remote NIU for extending CMX topologies to field-distributed controllers.

IC695ACC302 – Legacy RX7i adapter for seamless CMX integration in mixed-generation systems.

When readying the GE IC695CMX128-EG for your RX3i backplane, cross-check CPU firmware—version 8.0 or later ensures full interrupt handling; earlier builds may limit packet sizes to 32 bytes, capping globals. Opt for a slot with fiber routing clearance, as the SC connectors need 5cm bend radius to avoid insertion loss—test continuity with a light meter pre-power to confirm under 5 dB/km attenuation. Backplane parity matters: pair with universal racks only, and set the memory offset in Proficy to dodge overlaps with %W I/O tables, which could shadow critical refs. For rings, assign unique node IDs via rotary switches before insertion, then validate propagation with a loopback test to weed out address ghosts.

In the field, stewardship is straightforward and revealing. Fortnightly, monitor the fault LED during cabinet checks—amber pulses often trace to dirty transceivers, cleared with a lint-free swab and 99% isopropyl. Biannually, export status registers to log reflection latencies; drifts over 2 μs signal fiber micro-bends, prompting a segment swap. In variable climates, quarterly humidity scans guard against condensation on optics—use desiccants if exceeding 85% RH. Annual full-ring simulations, forcing a node drop via software, benchmark recovery to under 1 ms, archiving trends for warranty claims. These protocols embed into existing rounds, fortifying the module’s autonomy so your focus stays on orchestration, not oversight.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626