Description

Many products have not yet been launched, please contact us for more product information.

We have 16 shared warehouses worldwide, so please understand that sometimes it may take several hours to accurately respond to you. Of course, we will reply to your question as soon as possible.

In sprawling manufacturing floors, water treatment facilities, and high-volume packaging lines, control systems must juggle dozens of I/O modules, processors, and network interfaces without missing a beat. The GE IC695CHS016FA steps in as the foundational rack that holds it all together, letting engineers populate dense setups for motion control, batch processing, or SCADA integration where downtime from expansion limits simply isn’t an option. Deployed in GE RX3i PACSystems PLC environments, it handles the electrical and mechanical demands of 24/7 operations in dusty warehouses or vibration-heavy steel mills, ensuring signals flow reliably between field devices and logic solvers

Plant managers specify the GE IC695CHS016FA when upgrading legacy Series 90-30 systems to modern PACSystems, as its universal design bridges old serial modules with high-speed PCI options, supporting everything from discrete sensors to high-resolution analog loops. In these scenarios, it powers synchronized drives on conveyor lines or precise PID loops in HVAC skids, where slot density directly impacts scalability during peak production ramps. Used in industrial automation across automotive assembly, pharmaceutical blending, and utility substations, this backplane keeps expansion straightforward even as process complexity grows. Technicians value how it simplifies rack builds by accommodating single- or double-wide modules without custom adapters.

You’ll also spot the GE IC695CHS016FA in remote pump stations or distributed energy sites, where fitting 16 slots into compact enclosures means fewer cabinets and lower footprint costs. Applicable in control systems that demand future-proofing—like adding cybersecurity gateways or AI-driven predictive modules—it forms the backbone for hybrid networks blending Ethernet/IP with legacy protocols. For integrators tackling brownfield projects, its robust grounding and serial expansion port make it a reliable choice for extending racks across cabinet rows without signal degradation.

Product Introduction & Positioning

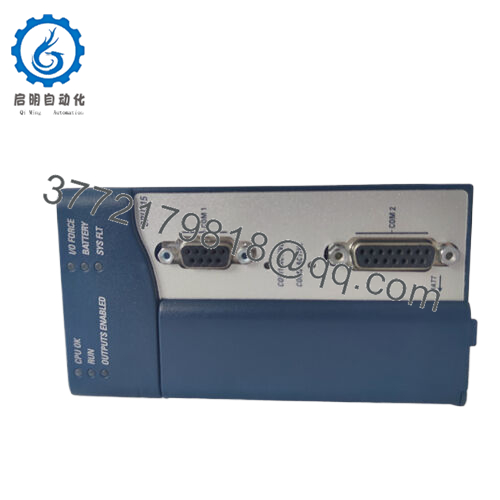

The GE IC695CHS016FA is a 16-slot Universal Backplane from the GE RX3i PACSystems family, designed as a dual-bus rack that seamlessly supports both PCI-based (IC695) high-performance modules and legacy serial (IC694) I/O carriers. It occupies a horizontal rack position in standard PLC enclosures, distributing power and data across slots for controllers, network adapters, and specialty cards in demanding automation architectures. Positioned at the core of RX3i systems, it enables flexible population strategies, from compact CPU-only setups to fully loaded I/O farms handling hundreds of points.

Within a typical RX3i configuration, the GE IC695CHS016FA integrates with power supplies like the IC695PSD series and CPUs such as the IC695CPU, forming a scalable chassis that handles real-time tasks like high-speed counter inputs or motion axis synchronization. Its serial expansion connector allows daisy-chaining to remote backplanes, ideal for multi-rack plants where centralizing logic but distributing I/O cuts wiring runs. Single- and double-slot module support, plus integrated slot numbering, streamlines configuration in Proficy Machine Edition software.

Engineers choose the GE IC695CHS016FA for its role in migration paths, letting plants evolve from 90-30 without full rip-and-replace. This backplane’s grounding bar and isolated +24 V input enhance EMC performance in noisy environments, while filler modules for unused slots protect against dust ingress. For system builders, it delivers the density and compatibility that turn complex retrofits into routine upgrades, backed by GE’s extensive PACSystems documentation.

Key Technical Features & Functional Benefits

The GE IC695CHS016FA‘s dual-bus architecture sets it apart, combining a high-speed PCI backbone for modern modules with a serial bus for proven I/O, so teams can mix-and-match without performance bottlenecks. Sixteen slots accommodate everything from single-wide digital packs to double-wide process control units, with printed slot numbers aiding quick mapping during commissioning. Built-in features like a grounding bar, backplane ground point, and serial expansion port ensure clean power distribution and reliable inter-rack links up to hundreds of meters.

Ruggedness defines its hardware design: rated for IP20/NEMA Type 1 enclosures with 4-inch clearance on all sides for natural convection cooling, it operates steadily from -20°C to +60°C amid factory heat or chiller failures. Dimensions of roughly 5.6 x 23.7 x 5.8 inches fit standard 19-inch racks, while low internal power draw—240 mA at 5 VDC and 600 mA at 3.3 VDC—eases thermal budgeting in dense populations. Mechanical enhancements in the FA revision improve PCI connector engagement, reducing intermittents from vibration or thermal cycling.

Functionally, the GE IC695CHS016FA boosts system uptime through robust isolation and noise immunity upgrades, critical for Ethernet-heavy setups exposed to VFD harmonics or welders. It supports ATEX Zone 2 certification in later revisions, opening doors to hazardous locations, and pairs effortlessly with GE’s high-availability redundancy options. Long-term value lies in its forward compatibility—firmware-agnostic design means CPUs and modules upgrade independently, extending rack life across 15-20 year plant cycles without chassis swaps.

Reliability extends to maintenance ease: no active components mean MTBF in the millions of hours, with visual indicators and diagnostic access via the backplane simplifying fault isolation. For PACSystems users, this backplane cuts integration time, letting focus shift to application logic rather than hardware quirks.

- IC695CHS016FA

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | IC695CHS016FA |

| Brand | General Electric (GE) Fanuc |

| Type | 16-Slot Universal Backplane |

| Series | RX3i PACSystems |

| Backplane Buses | PCI (IC695) and High-Speed Serial (IC694) |

| Number of Slots | 16 (single- and double-wide module support) |

| Power Requirements | 240 mA @ 5 VDC, 600 mA @ 3.3 VDC; +24 VDC isolated input |

| Operating Temperature | -20°C to +60°C |

| Mounting | Horizontal 19-inch rackmount |

| Dimensions | 5.57 x 23.7 x 5.80 inches (H x W x D); approx. 43 x 28 x 6.5 cm |

| Weight | Approximately 1.56 kg (3.44 lbs) |

| Clearance Required | 4 inches (102 mm) on all sides |

| Enclosure Rating | IP20, NEMA/UL Type 1 |

| Grounding | Integral bar and backplane point |

| Expansion | Serial connector for remote backplanes |

| Certifications | ATEX Zone 2 (later revisions), EU-RoHS compliant |

Related Modules or Compatible Units

IC695CPU315 – High-performance CPU that plugs directly into the IC695CHS016FA, handling complex ladder logic and data logging.

IC695PSD120 – Power supply module for the IC695CHS016FA, providing stable +5/+3.3/+24 V rails across all slots.

IC695CHS012FA – 12-slot variant for space-constrained racks, sharing the same dual-bus design as IC695CHS016FA.

IC694ALG392 – Serial I/O module compatible with the IC695CHS016FA‘s legacy bus, for analog integration in mixed systems.

IC695NIU001 – Network interface unit that leverages the IC695CHS016FA PCI bus for Ethernet/IP and Profinet connectivity.

IC695ACC310 – Battery backup module to pair with CPUs in the IC695CHS016FA, ensuring memory retention during outages.

IC695CHS016DA – Updated revision with mechanical enhancements, direct drop-in for IC695CHS016FA in high-vibration spots.

Installation Notes & Maintenance Best Practices

Start GE IC695CHS016FA installs by selecting a NEMA 1 or better enclosure with exactly 4 inches of clearance around the backplane for airflow—poor ventilation spikes slot temperatures, risking module derates in summer peaks. Secure it horizontally in a 19-inch rack using captured screws, then attach the grounding bar to chassis earth before adding power supplies; this sequence prevents latch-up during initial energization. Plan slot layout upfront in Proficy: reserve doubles for motion cards, fill empties with blankers to block debris, and route serial expansions with shielded cable under 100 meters to avoid attenuation.

Keep the GE IC695CHS016FA humming with bi-annual wipe-downs using ESD-safe vacuums—no solvents on PCBs—and torque checks on all module connectors post-vibration events like conveyor startups. Monitor power rail LEDs on supplies for droops, and use Proficy diagnostics to scan backplane integrity annually; flag any serial bus retries exceeding 1% as early wear signs. Firmware-agnostic slots mean module swaps rarely need reconfiguration, but rotate spares every 7 years and log environmental data to predict dust-related faults in non-climate-controlled sites.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626