Description

In industrial automation, the quest for precise actuation often uncovers a subtle but persistent hurdle: translating digital commands into analog signals that drive field devices with unerring accuracy, especially when noise, load variations, or channel crosstalk threaten to introduce offsets or drifts. Consider a chemical mixing skid where proportional valves must respond to setpoint changes within milliseconds—any deviation in output current could skew blend ratios, leading to off-spec product, regulatory headaches, or scrapped batches that erode margins. This is precisely the challenge the GE IC695ALG704-AB addresses head-on. As a 4-channel analog output module for PACSystems RX3i, it delivers non-isolated voltage or current signals with exceptional resolution and stability, ensuring your process control loops maintain fidelity from controller to actuator in even the most dynamic environments. It stands as a cornerstone for high-reliability I/O architectures, where every microamp or millivolt counts toward seamless operation.

Engineers gravitate to the GE IC695ALG704-AB in scenarios demanding granular control without the bulk of multi-module racks—think expanding a DCS in a pharmaceutical bioreactor, where 4-20 mA loops modulate agitator speeds, or retrofitting a HVAC system for zoned dampers in a data center, where signal precision directly impacts energy efficiency. It proves essential when modular integration is key, allowing independent channel configuration to match diverse field needs without over-spec’ing the entire setup. In these process control applications, the module’s 15.6-bit resolution captures nuanced digital values, minimizing quantization errors that could destabilize PID tuning or feedback cascades. By supporting both voltage (0-10V or ±10V) and current modes per channel, it adapts to legacy transducers or modern positioners, reducing the need for external converters and streamlining I/O signal paths. The GE IC695ALG704-AB also incorporates self-diagnostics to flag open loads or over-range conditions early, preventing minor glitches from escalating into system-wide faults. For teams navigating brownfield upgrades, its compatibility with RX3i firmware 3.0+ means drop-in deployment that preserves existing logic, while the 8 ms update rate keeps pace with fast-scan cycles essential for continuous processes. Ultimately, in an landscape of tightening tolerances and remote monitoring, this module doesn’t just output signals—it fortifies the reliability that keeps industrial automation predictive, not reactive, turning potential variances into consistent performance.

Analog outputs aren’t set-it-and-forget-it; they demand vigilance against environmental creeps that dull responsiveness. The GE IC695ALG704-AB embeds scaling and fault detection to normalize loads up to 850 ohms, so your valve stems or chart recorders see true proportional drive, not attenuated echoes.

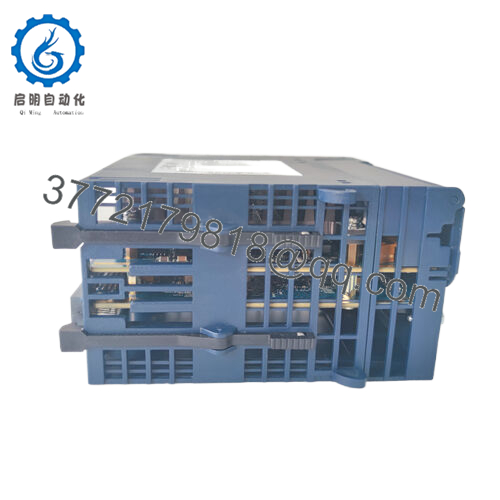

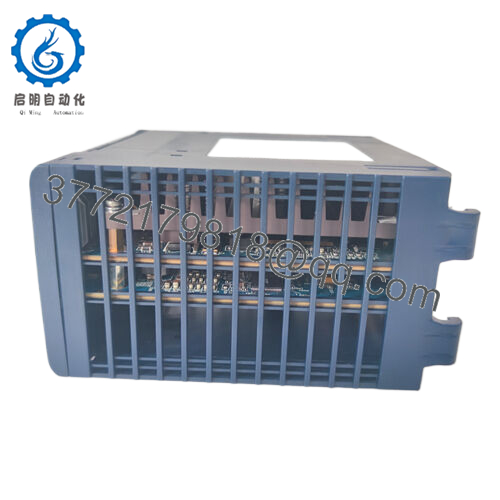

Within the PACSystems RX3i universal backplane, the GE IC695ALG704-AB occupies a single slot as a dedicated analog output peripheral, converting up to four single-ended digital words from the CPU into precise field signals via screw terminals on the front panel. It draws regulated power from the rack while interfacing directly with the internal bus, mapping outputs to %AQ registers accessible by ladder rungs or structured text—ideal for modulating devices like pneumatic regulators or variable frequency drives in a closed-loop setup. This positions it squarely in the I/O layer of your automation stack: downstream from the CPU’s decision engine but upstream of field cabling, where it handles per-channel mode selection (voltage/current) and scaling factors to align with engineering units, all configurable via Proficy Machine Edition without halting the scan.

Its diagnostics shine through: onboard status bits report channel health—shorts, breaks, or excursions—while front LEDs indicate module OK and per-channel activity, feeding alerts to HMIs like Proficy HMI/SCADA for operator visibility. Though non-isolated, it leverages the backplane’s common ground to minimize noise in low-voltage loops, and supports diagnostics protocols like CIMPLICITY for trend logging. In a broader system, envision it paired with input siblings in a remote rack, where the RX3i CPU polls outputs every cycle (as low as 1 ms), refreshes signals, and syncs with Ethernet modules for supervisory oversight—no proprietary middleware required. Redundancy comes via rack-level hot-swap or dual-module mirroring for failover, ensuring outputs hold last state during transitions. Configuration is intuitive: download the GFK module profile, assign ranges, and test with simulated loads, but calibrate post-install to account for cable capacitance. This fluid integration elevates your I/O architecture, bridging digital intent to analog action with the determinism that underpins resilient process control.

| Specification | Details |

|---|---|

| Model Number | IC695ALG704-AB |

| Brand | GE (Emerson Automation) |

| Type | 4-Channel Non-Isolated Analog Output Module |

| Input Voltage | 3.3 VDC / 24 VDC (from backplane) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | RX3i Universal Backplane |

| Dimensions | 14.7 cm x 5.1 cm x 11.2 cm |

| Weight | 0.24 kg |

| Interface/Bus | RX3i Backplane Bus |

| Compliance | CE, UL, RoHS |

| Supported Protocols | PACSystems RX3i Native |

| Typical Power Draw | 375 mA @ 3.3 VDC, 160 mA @ 24 VDC |

Integrating the GE IC695ALG704-AB into your RX3i setup yields outputs that hold steady through load shifts or power fluctuations, engineered for the endurance of round-the-clock process control where a 0.1% drift could unbalance a reactor feed. This performance consistency means your control valves track setpoints with surgical precision, stabilizing flows that directly correlate to yield consistency and reduced waste—often translating to measurable gains in throughput without added tuning efforts. Maintenance efficiency follows naturally: built-in fault latching and diagnostic interrupts allow pinpointing issues like a stuck channel via software reads, sparing technicians the guesswork of multimeter hunts across cabinets and cutting downtime by focusing interventions where they matter.

The module’s per-channel flexibility shines in easing integration, letting you mix voltage for local indicators and current for remote loops in the same footprint, which trims engineering overhead during expansions—no need for parallel racks or signal boosters. In EMI-laden zones, its low-impedance drive fortifies against pickup, ensuring high-reliability I/O signals that feed clean data back to analytics tools, enabling trends that forecast actuator health before failures mount. Over time, this reduces the hidden costs of variability, like energy spikes from imprecise dampers, fostering the operational smoothness that elevates OEE metrics.

For forward-looking teams, the GE IC695ALG704-AB unlocks scalability without compromise—add channels as processes evolve, all while its 8 ms refresh keeps loops agile for emerging demands like hybrid batch-continuous runs. This isn’t mere connectivity; it’s the quiet assurance of outputs that perform as engineered, compounding reliability into long-term savings and the adaptability that defines cutting-edge industrial automation.

- IC695ALG704-AB

- IC695ALG704-AB

The GE IC695ALG704-AB deploys reliably in water treatment facilities, driving 4-20 mA signals to chemical dosing pumps across clarifiers, where its voltage/current versatility ensures precise dosing amid varying loads and upholds critical system uptime in corrosive, humid process control environments. In semiconductor fabs, it modulates gas flow controllers with ±10V outputs for etch chambers, delivering the resolution needed for sub-micron uniformity under cleanroom constraints and fast data cycles that prevent wafer defects.

Food processing lines harness it for temperature zoning in extruders, configuring channels for 0-10V to steam valves while withstanding washdown vibrations—essential for consistent texture in high-volume runs without flavor inconsistencies. These applications underscore its role in demanding sectors, from power plant fuel actuators to pharmaceutical fermenters, where the GE IC695ALG704-AB guarantees the analog backbone for uninterrupted, compliant operations in industrial automation.

IC695ALG508 – 8-channel isolated variant for applications requiring channel-to-channel separation in noisy setups.

IC695ALG600 – High-density 16-channel output module for compact, multi-loop control expansions.

IC695ALG408 – Thermocouple/RTD input companion to balance output modules in closed-loop sensing.

IC694ALG392 – Legacy-compatible analog output for hybrid RX3i/Series 90-30 migrations.

IC695NIU001 – Ethernet NIU add-on for remote rack deployment of ALG modules.

IC695CPU315 – Paired CPU with 512KB memory for handling ALG data in mid-range systems.

IC695PWR058 – Energy-efficient power supply to sustain ALG loads in dense backplanes.

Before committing the GE IC695ALG704-AB to your RX3i backplane, audit CPU firmware—version 3.0 minimum, but 9.0+ unlocks enhanced scaling options; flash if needed to avoid reference table mismatches. Position it away from high-current modules to curb inductive coupling, as non-isolation amplifies proximity effects—aim for slots with 2cm airflow gaps in sealed enclosures to respect the 0-60°C bounds. Terminal prep: strip wires to 7mm, torque to 7 in-lbs, and verify polarity with a loop calibrator pre-power; for current mode, confirm loads under 850 ohms to prevent overcurrent trips. In Proficy, import the module profile early, assign %AQ offsets, and run a dry simulation to validate range mappings against your field devices.

In operation, upkeep revolves around observable cues that integrate into patrols. Bi-monthly, query status bits via the programming port—fault codes like 0x8000 signal open circuits, prompting a quick terminal reseat. Quarterly, perform a full-channel sweep with a precision load box to check linearity, logging deviations to spot any zero-offset creep from thermal cycling. In dusty or variable-temp sites, inspect for condensation on terminals and apply dielectric grease if humidity exceeds 95% RH. Annual firmware audits ensure parity with CPU updates, while exporting diagnostic logs helps baseline performance. These measures form a low-touch routine, empowering your team to sustain peak output integrity without derailing daily priorities.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626