Description

In the precision-driven arena of industrial automation, capturing a spectrum of analog inputs from thermocouples, RTDs, and transmitters without compromising on accuracy or adaptability can dictate the difference between seamless process control and erratic feedback loops plagued by signal distortion or range limitations. Engineers in high-density sensor arrays often confront the fragmentation of dedicated modules for voltage, current, or temperature signals, leading to cluttered backplanes, escalated wiring complexity, and vulnerability to thermal gradients that skew readings—issues that undermine closed-loop stability, inflate calibration demands, and heighten risks in environments where a 0.1°C offset could trigger off-spec batches or safety halts. The GE IC695ALG600 meets this challenge as an 8-channel universal analog input module for the PACSystems RX3i platform, offering configurable versatility across thermocouple types, RTDs, resistive bridges, and current/voltage sources to deliver high reliability in consolidated I/O signal processing. When your setup spans furnace monitoring with J/K thermocouples alongside pressure loops via 4-20 mA in a single rack, this module unifies the front end, ensuring crisp data ingestion that bolsters predictive diagnostics without the overhead of multi-module sprawl.

Envision a heat treatment oven where zone temperatures from embedded TCs must align with flow sensors under vibrational stress, or a bioreactor pulling pH and conductivity from mixed probes amid sterile steam—the GE IC695ALG600 stands as the cornerstone for system stability in these process control environments, where mismatched input types could necessitate custom scalers or isolated converters, ballooning footprint and fault paths. Lacking this universality, you’d navigate frequent sensor swaps or software workarounds to handle bipolar voltages alongside linear resistances, eroding throughput and complicating fault isolation in PROFINET-linked networks. Its dual isolated groups—four channels each—partition signals to curb crosstalk, while integrated cold junction compensation (CJC) channels auto-correct for ambient shifts, preserving microvolt fidelity over extended runs. In greenfield RX3i builds or 90-30 migrations, it leverages Proficy configuration for per-channel tuning, from NiFe RTD linearization to ±20 mA scaling, embedding the flexibility to evolve with process tweaks. Core to its value, the GE IC695ALG600 reframes analog acquisition from a modular maze to a streamlined sensor hub, empowering your industrial automation to layer advanced analytics on unassailable input foundations amid the flux of operational variables.

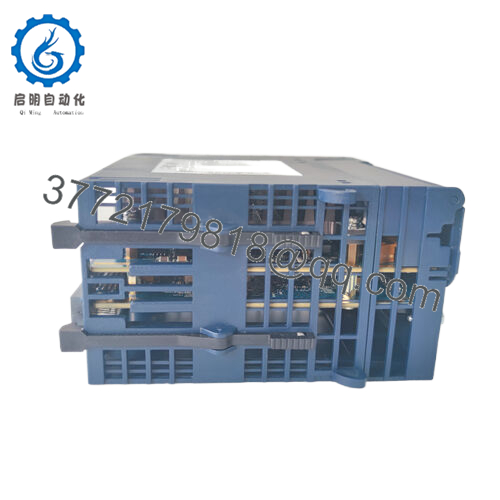

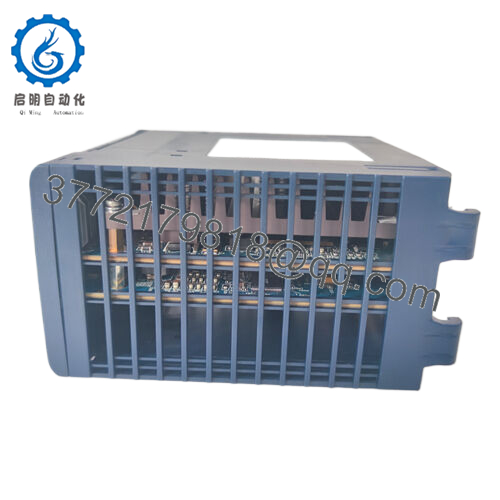

The GE IC695ALG600 tucks into any available slot on the RX3i universal backplane, drawing 5V logic from the bus while sourcing field excitation from an external 24V DC supply to power its multiplexed ADC and sensor interfaces. Its eight single-ended channels flex across modes—0-20 mA, 4-20 mA, ±20 mA currents; 0-5V, 1-5V, 0-10V, ±10V voltages; 0-4000Ω resistances; PT/NiFe/Cu RTDs; B/C/E/J/K/N/R/S/T thermocouples—all resolved at 16 bits (effective 15-bit for signed ranges) with update rates as quick as 5 ms per channel in fast-scan configs, feeding %AI words to the CPU for immediate loop integration. The two dedicated CJC inputs mount externally for precise TC referencing, compensating drifts to 0.1°C accuracy, while group isolation at 250Vrms shields against ground potentials from adjacent high-voltage zones.

In the automation stack, it anchors the field sensing layer, streaming digitized values via backplane DMA to the RX3i controller for PID processing or Ethernet handoffs to SCADA, with built-in filters tunable for 50/60 Hz rejection to tame EMI in drive-heavy bays. Diagnostics shine through: per-channel LEDs signal underrange/overrange or open wires, with %SQ status bits latching faults for HMI trending, and self-calibration routines invoked via COMMREQ to baseline offsets without module pulls. It supports redundancy in high-availability frames, holding last valid reads during failovers under 30 ms, and scales seamlessly with VersaMax gateways for remote drops up to 1 km on shielded twisted pair. Unlike rigid voltage-only boards, the GE IC695ALG600‘s software-defined ranges eliminate hardware jumpers, fitting into dense architectures where a furnace skid might blend TC heat profiles with mA flow data—commission it with a terminal block snap-in and profile load, shifting emphasis from wiring wars to signal validation in your layered process control paradigm.

| Specification | Details |

|---|---|

| Model Number | IC695ALG600 |

| Brand | GE (Emerson) |

| Type | 8-Channel Universal Analog Input Module |

| Input Voltage | 24 V DC (user supply) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | RX3i Universal Backplane |

| Dimensions | 5.5″ x 0.75″ x 7.5″ |

| Weight | 0.75 lb |

| Interface/Bus | RX3i Backplane |

| Compliance | CE, UL, CSA, Class I Div 2 |

| Supported Protocols | N/A (PLC Backplane/COMMREQ) |

| Typical Power Draw | 150 mA @ 5V (backplane); 250 mA @ 24V (user) |

Incorporating the GE IC695ALG600 elevates input trustworthiness with its 16-bit conversion and per-group isolation, holding accuracy to 0.05% of span across TC linearizations—vital for furnace zoning where a skewed K-type reading could unbalance soaks, often refining temperature uniformity to cut scrap by 5-10% without external conditioners. This precision permeates loop dynamics, as configurable burnout detection flags failed probes early, averting cascade faults in multivariable cascades like pressure-compensated flows, and its 5 ms latency aligns with high-speed RX3i scans for responsive overrides in batch reactors. Engineered for sensor diversity, it absorbs resistances up to 4000Ω without excitation overloads, stabilizing bridges in strain monitoring amid mechanical chatter and trimming the engineering overhead of type-specific swaps.

Diagnostic depth amplifies this: embedded averaging modes smooth noisy mV signals from remote TCs, delivering performance consistency that sustains 99.9% data validity in EMI-saturated zones, while hot-swappable insertion preserves critical system uptime during maintenance windows—often without logic interruptions in redundant setups. Over the arc of deployment, the GE IC695ALG600 extends MTBF past 300,000 hours through auto-calibration that offsets drift annually, reallocating calibration crews from manual spans to data-driven tunings like Kalman filters on raw streams. It’s the input oracle that demystifies sensor fusion, enabling industrial automation to transcend basic monitoring toward anomaly-anticipating intelligence, all on a chassis of inherent adaptability.

Power generation boilers embed the GE IC695ALG600 to ingest draft TC voltages and drum level currents under flue gas turbulence, where RTD windbox temps feed combustion trims with high reliability for I/O signals in continuous uptime regimes bound by grid demands. In food processing extruders, it unifies barrel PT RTDs with moisture transmitter mA amid thermal cycles, supporting fast data cycles for recipe guards that enforce texture specs without variance. Chemical reactors deploy it for catalyst bed profiles via E-type TCs paired with pH voltages in corrosive housings, upholding process control environments where input fidelity secures yield thresholds and safety interlocks. These integrations reveal its chameleon-like prowess, galvanizing industrial automation through a kaleidoscope of sensing where universality underpins unerring insight.

- IC695ALG600

- IC695ALG600

- IC695ALG600

IC695ALG508 – 8-channel voltage/current input variant for non-temperature focused loops with faster aggregation

IC695ALG600-AA – Earlier firmware iteration for baseline RX3i compatibility in staged upgrades

IC694ALG392 – 8-channel analog output counterpart for balanced input-output cascades

IC695CPU315 – High-throughput RX3i CPU to leverage the module’s 5 ms updates in dense programs

IC695RTD008 – Dedicated 8-channel RTD module as a specialized offshoot for pure temperature arrays

IC694ALG442 – Combo input/output sibling for hybrid analog needs in compact nodes

IC695PWR330 – Fortified power supply to underpin 24V stability in sensor-heavy banks

IC693ALG600 – Series 90-30 universal input equivalent for legacy-to-RX3i migrations

When queuing the GE IC695ALG600 for backplane docking, align your RX3i firmware to version 7.0 or higher—these unlock refined TC tables in the CC profile—and simulate channel loads in Proficy with dummy signals to vet scaling before live ties, catching underrange biases early. Vet the 24V user supply for <50 mV ripple under 300 mA via oscilloscope, fusing at 2A to buffer startup surges, and opt for shielded 20 AWG for TC leads, grounding at the module to exploit CJC isolation; undertorqued terminals at 9 in-lbs invite microphonics in vibe-prone spots.

Active stewardship is nuanced: fortnightly, scan %SQ for diagnostic latches—recurring open-wire flags on a group warrant probe continuity with a decade box—and run a monthly full-range sweep on each channel, benchmarking against 0.05% linearity to flag ADC creep. Semiannually, reposition CJC sensors if enclosure airflow shifts, verifying compensation to ±0.2°C with an ice bath, and yearly self-cal via COMMREQ to archive baselines for drift tracking. These cadences mine the GE IC695ALG600‘s telemetry veins to preempt signal shadows, infusing your industrial automation with foresight minus the drag of exhaustive audits.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626