Description

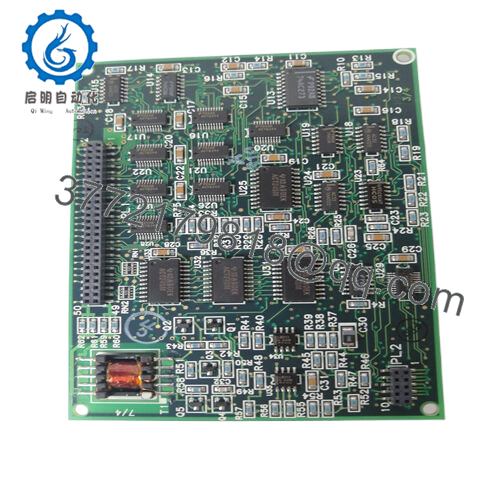

Product Model: GE IC660ELB912J

Product Brand: GE / Emerson (formerly GE Fanuc)

Product Series: GENI / µGENI / Genius I/O

Product Features:

- Acts as a network interface daughterboard (µGENI) to a host CPU module

- Handles communication between host and up to 30 I/O devices on the GENI bus

- Supports multiple baud rates (38.4K, 76.8K, 153.6K, extended)

- Requires 5 VDC logic power and integrates dual-port RAM for data exchange

- IC660ELB912J

Product Role & System Fit

In automation systems employing the GE IC660ELB912J, this module acts as the µGENI (micro-Genius) network interface board – essentially a daughterboard that sits on a host PCIM (PC Interface Module) card. The host (for example, a CPU or embedded controller) communicates with this daughterboard via shared memory, and the µGENI handles the traffic between the host and the Genius I/O bus.

The IC660ELB912J offloads much of the I/O management burden from the host, by maintaining an image of I/O device states, handling initialization, and diagnosing faults for up to 30 devices on the GENI bus. In effect, it frees the host to run control logic rather than busywork of I/O communication.

When integrating into a control architecture, one typically places IC660ELB912J on a PCIM card such as IC660ELB921 (single channel) or IC660ELB922 (dual slot) in systems built around GENI / Genius I/O. The module communicates across the GENI network to remote I/O modules (digital, analog, specialty) and also supports global data and diagnostic messaging among controllers.

By placing this functionality into a dedicated interface board, system designers can scale I/O counts, partition traffic, or interface legacy GENI networks with newer host systems. The IC660ELB912J thus becomes a bridge between host computation and distributed I/O hardware.

Technical Features & Benefits

The GE IC660ELB912J offers several features that make it practical and robust in industrial control settings:

- Baud Rate Flexibility: It supports standard and extended GENI bus speeds: 38.4K, 76.8K, 153.6K, and 153.6K extended mode.

- Device Support: It can manage up to 30 bus devices per daughterboard, allowing relatively large I/O networks to be handled by one interface.

- Dual-Port RAM Architecture: Communication between the host and GENI I/O bus occurs through shared RAM, enabling simultaneous access without contention.

- Microprocessor Integration: In its internal design, it uses a Motorola 6303 (or similar) microcontroller plus a bus manager (e.g. 64180) to arbitrate communication and error checking.

- LED Diagnostics: It typically provides status LEDs labeled GENI OK and COMMS OK (or equivalent) on the host card for visual health indication.

- Low Logic Power Requirement: It requires a stable 5 VDC supply to power the logic circuits.

- Host Independence: The interface allows the host to treat GENI I/O devices almost transparently, abstracting the details of bus communication.

Because the IC660ELB912J is functionally passive (no heavy power or actuation), its failure modes tend to be connector wear, RAM corruption, or component aging—not frequent mechanical stress. When properly installed and maintained, many of these interface boards continue to operate reliably for years.

Technical Specifications

| Specification | Description |

|---|---|

| Model | GE IC660ELB912J |

| Alternate Name | µGENI / Micro Genius Network Interface |

| Series / Family | GENI / Genius I/O |

| Function | Network interface daughterboard for GENI bus |

| Bus Devices Supported | Up to 30 per daughterboard |

| Supported Baud Rates | 38.4K, 76.8K, 153.6K (standard & extended) |

| Logic Supply Voltage | 5 VDC |

| Current Draw | ~ 400 mA (or up to 1.0 A depending on host module) |

| Operating Temperature | 0 °C to +60 °C (typical) |

| Storage Temperature | –40 °C to +125 °C |

| Humidity | 5% to 95% (non-condensing) |

| LED Indicators | GENI OK, COMMS OK |

| Memory Size | Approximately 16 KB shared RAM for single daughterboard setup |

| Mounting / Format | Daughterboard mounted onto PCIM host card (IC660ELB921 / IC660ELB922) |

Applications & Industry Context

Controllers in industrial and utility automation often need to scale I/O or interface with legacy GENI I/O networks. The GE IC660ELB912J enables modern computing hosts to take on that role without redesigning existing I/O hardware.

For example, in power generation or turbine control systems (where older GENI buses were once widely used), the µGENI links a modern host processor (or PC-based control unit) to existing I/O modules. By doing so, it preserves investment in I/O hardware while updating the central control logic.

In manufacturing plants, you might find the IC660ELB912J in retrofit environments: replacing old controllers but retaining the I/O layer. It also appears in distributed control panels that aggregate local I/O but report data to a supervisory system through one host interface.

Because the µGENI approach is relatively compact and lightweight, it is also suited to embedded control systems or mezzanine cards in compact enclosures. Its protocol support and device capacity make it sufficient for mid-sized control applications without overbuilding.

Repair houses often refurbish the IC660ELB912J, as indicated by suppliers listing remanufactured units. qualitrol.com+1 This is because the core logic is mature and stable; component replacements (e.g. RAM, logic chips) during repair cycles often restore full functionality.

As GENI / Genius I/O networks persist in legacy systems, this interface board remains relevant for bridging older and newer automation architectures.

Installation & Maintenance Insights

Installing the IC660ELB912J requires care to maintain signal integrity and reliability. The board mounts as a daughterboard onto the PCIM host card, typically using standoffs or spacers to ensure airflow and spacing. Avoid placing it within 1/8 inch of another board to ensure cooling and clearance.

The module should not be glued or adhered; mechanical fasteners are preferred for serviceability. Additionally, ensure the host system provides stable 5 V DC logic power before activation.

During commissioning, LED status lights (GENI OK, COMMS OK) serve as primary diagnostic indicators. If communication is not established, check host interface, baud rate settings, wiring to the GENI bus, and device addressing.

Periodic inspection is minimal. Technicians should verify connector solder joints, clean dust from the board to ensure thermal dissipation, and exercise the module (power cycle) during scheduled maintenance. If intermittent behaviors occur, re-seating the module or refreshing firmware can resolve transient memory errors.

Because the IC660ELB912J is primarily electronic (versus electromechanical), failure modes are usually in memory, connector wear, or component aging. Keeping a spare in inventory is good practice in legacy systems. Replacing a defective card is relatively fast: power off host, unmount the daughterboard, mount the replacement, ensure power and bus settings are correct.

Be careful with electrostatic discharge (ESD) during replacement or handling. Always use ESD-safe practice when handling logic boards.

If multiple µGENI boards are used (for example, dual slot host modules), coordinate configurations (addressing, baud rates) to avoid bus conflicts.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626