Description

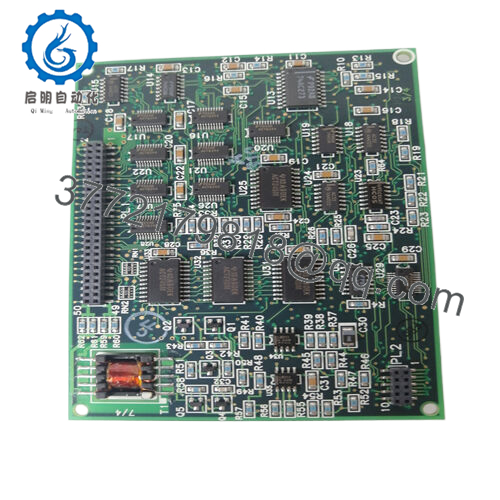

The GE IC660ELB912 analog input module is a critical component in industrial automation systems, designed to directly interface with analog sensors and transmit accurate data to higher-level control systems. It has multiple input channels and can receive different types of analog signals with high accuracy and stability, such as voltage and current inputs. This module converts these analog signals into digital data that is easy to process by a programmable logic controller (PLC) or distributed control system (DCS).

GE IC660ELB912

This module seamlessly integrates with GE’s Series 60 and other compatible control platforms through the system’s backplane architecture. It uses industry standard protocols for communication, ensuring compatibility with various existing automation components. The GE IC660ELB912 also integrates built-in diagnostic functions to continuously monitor the status of each input channel and detect any signal abnormalities or module failures. Once a problem is identified, it can quickly alert the control system, allowing engineers to take immediate corrective measures. GE IC660ELB912 is located at a lower level of the automation architecture and serves as a reliable data gateway, ensuring accurate and timely information flows from on-site sensors to the control center, thereby promoting informed decision-making and precise process control.

GE IC660ELB912

Technical specifications:

Model number IC660ELB912

Brand GE

Type Analog Input Module

Input voltage range -10 V to 10 V, 0-20 mA, 4-20 mA

Working temperature range: 0 ° C to 60 ° C

Installation method: DIN rail

Size 100 x 50 x 80 mm

Weight 200 g

Interface/Bus Series 60 Backplane

Compliance with CE and RoHS

Resolution of 12 bits

Sampling rate up to 100 samples per second

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

GE IC660ELB912

Main features and advantages:

Its high-precision design is specifically designed for precise signal conversion, ensuring reliable and consistent data collected from on-site sensors. This accuracy is crucial for maintaining product quality in the manufacturing process, optimizing energy consumption in power plants, and ensuring the safety and efficiency of refinery operations. This module is capable of processing various analog input signals without the need for multiple dedicated modules, thereby reducing hardware costs and simplifying system design.

The easy integration with existing GE control systems significantly reduces the engineering workload required for system upgrades or expansions. Engineers only need to install GE IC660ELB912 onto the backplane, without the need for large-scale rewiring or software modification, saving time and money. The built-in diagnostic function improves maintenance efficiency by enabling rapid identification and resolution of problems. The maintenance team does not need to spend hours troubleshooting data related issues, but can rely on diagnostic alerts from modules to accurately locate the root cause of problems and take corrective measures in a timely manner. This proactive maintenance approach minimizes unplanned downtime, ensures smooth operation of industrial processes, and ultimately improves productivity and profitability.

GE IC660ELB912

Application areas:

In the power generation industry, it is used to monitor key parameters such as voltage, current, and temperature in generators, transformers, and other electrical equipment. The precise data collected by GE IC660ELB912 enables operators to optimize power generation, detect potential faults early, and ensure stable operation of the power grid.

In the chemical processing industry, this module plays a crucial role in monitoring process variables such as pressure, flow rate, and chemical concentration in reactors and pipelines. These accurate data are used to control chemical reactions, maintain product quality, and ensure compliance with safety and environmental regulations. In addition, in manufacturing plants, GE IC660ELB912 is used to monitor the performance of machinery, such as motor temperature and vibration, which helps predict equipment failures and arrange preventive maintenance, thereby reducing expensive downtime and improving overall equipment efficiency.

GE IC660ELB912

Related products:

GE IC660ELB913: Provides higher resolution (16 bits), suitable for applications that require more accurate analog data acquisition.

GE IC693ALG223: A compatible analog input module with different channel configurations, suitable for systems with specific input requirements.

GE IC694ALG390: Designed specifically for high-speed analog data acquisition, suitable for applications that require fast sampling rates.

GE IC660ELB911: A cost-effective alternative product with slightly reduced functionality, suitable for applications with lower requirements.

GE IC697ALG221: With enhanced diagnostic capabilities, it is suitable for critical systems that require early fault detection.

GE IC660ELB912

Installation and maintenance:

Before installing the GE IC660ELB912 analog input module, engineers should carefully verify the compatibility of the input signal with the specified range of the module. Ensure that the voltage or current levels from the connected sensors are within an acceptable range to avoid damaging the module or causing inaccurate data collection. It is also crucial to check the available slots and power capacity of the backplane system to ensure proper installation and operation. Verifying the firmware versions of the control system and modules themselves, and updating them as necessary, can address potential compatibility issues and unlock new features.

It is crucial to regularly check the diagnostic indicator lights of the module for ongoing maintenance. These indicator lights can display the status of each input channel, as well as any error messages or warnings. The connection cables between sensors and modules should be checked regularly to ensure that they are firmly connected and free from damage or corrosion. Regularly calibrating analog inputs helps maintain the accuracy of collected data over time. A comprehensive annual review of module performance, including testing its sampling rate and signal conversion accuracy, will ensure that it continues to meet the requirements of industrial automation systems.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626