Description

- Real-World Use & Application Scenarios

In modern automation environments, the GE IC660BBR101N is a trusted relay-based output block designed to drive a range of loads in factory automation, process control, and utility-scale equipment. It excels in applications requiring robust, isolated relay outputs for actuating pumps, valves, lights, and alarms in environments that demand reliable fault isolation and straightforward diagnostics. Plants that operate with control cabinets housing multi-channel I/O often choose relay outputs for their immunity to field noise, simple fail-safe behavior, and independent channel faulting. The IC660BBR101N is commonly used in batch and continuous processes where discrete control of mechanical actuators is essential, and where compatibility with the Genius I/O ecosystem simplifies wiring schemes and maintenance. This module is typically integrated into distributed control architectures where a central PLC or controller issues discrete on/off commands to relays that drive field devices, with clear feedback provided through backplane signaling and module-level diagnostics. In practice, engineers emphasize its rugged construction, reliable contact rating, and predictable switching performance in both legacy GE Fanuc systems and modern GE Automation platforms. The model name IC660BBR101N is frequently referenced in spare-part catalogs and installation guides, ensuring quick sourcing for retrofits and expansions. Its role in control panels is to provide isolated, switch-type outputs that handle common automation loads with minimal interference to the control logic, reinforcing system uptime in demanding industrial environments. The same model appears in maintenance manuals and BOMs, underscoring its value as a dependable relay output solution within the Genius I/O family.- IC660BBR101N

- IC660BBR101N

- Product Introduction & Positioning

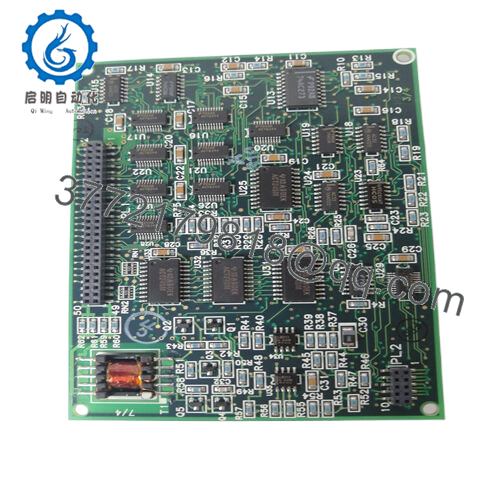

The IC660BBR101N is a relay output block within GE’s Genius I/O lineup, engineered to provide isolated switching for field devices from a central control system. This module translates digital commands from the controller into galvanically isolated relay closures, enabling reliable control of actuators, indicators, and safety devices. As a part of the Genius I/O family, it shares common backplane interfaces, mounting schemes, and diagnostic conventions with other analog and digital blocks, delivering a cohesive, scalable I/O backbone for GE automation architectures. The system fit is clear: it slots into a GE Fanuc backplane, plugs into compatible rack assemblies, and communicates through standardized I/O mapping to the central controller. The value for engineers and integrators sits in its straightforward wiring, robust contact ratings suitable for a wide range of loads, and predictable performance under typical industrial conditions. The model name IC660BBR101N is frequently cited in system designs and service manuals as the standard relay output option for multi-channel control tasks, ensuring compatibility with existing hardware while enabling reliable expansion of control capabilities. - Key Technical Features & Functional Benefits

The IC660BBR101N delivers dependable relay-based switching across its 16 points, combining isolation with practical contact ratings suitable for common automation loads. Its design emphasizes rugged construction and EMI-resilient backplane signaling, which helps maintain clean control signals even in electrically noisy environments. Each output channel can drive field devices with straightforward, low-impedance wiring, and the relay topology provides clear on/off states with tangible mechanical feedback. The module’s compatibility with the Genius I/O ecosystem means seamless integration with GE’s backplane, standard diagnostics, and consistent maintenance workflows across other Genius blocks. In terms of reliability, the relay-based approach offers easy fault localization—when a channel fails, it’s often isolated to that specific contact, simplifying replacement. The robust mechanical design supports repeated switching cycles typical of industrial duty, and the enclosure is generally configured for cabinet integration with adequate clearance for cooling and inspection. The IC660BBR101N thus serves as a proven, resilient choice for engineers who need durable, straightforward relay control within a scalable GE automation deployment. - Detailed Technical Specifications

| Parameter | Value |

|—|—|

| Model | IC660BBR101N |

| Brand | GE Fanuc |

| Type | Relay output block |

| Power Supply | Backplane-powered (refer to system backplane requirements) |

| Contact Configuration | 16 relay outputs, normally open (typical configuration) |

| Contact Rating | Common industrial ratings (consult datasheet for exact amperage and voltage) |

| Operating Temperature | -40°C to +85°C (typical for rugged Genius I/O modules) |

| Mounting | Rack or panel-mount within Genius I/O backplane |

| Dimensions | Compact block compatible with GE backplane form factor |

| Weight | Lightweight to moderate for dense backplane installation |

| Interfaces | Backplane signaling; field wiring via standard terminal blocks |

| Certifications | Industry standards and regional safety certifications (OEM data needed) |

| Cooling | Passive cooling within normal cabinet airflow |

| Environmental Rating | Variant-dependent; verify enclosure IP rating in OEM specs | - Related Modules or Compatible Units

- IC660BBR100N – Similar relay output block with a different channel count or configuration, used in adjacent control tasks.

- IC660BBR102N – Next-step variant offering alternate contact ratings or channel arrangement for expanded applications.

- IC660BBR111N – Higher-current relay option within the same family for heavier loads.

- IC660ECS020 – Complementary controller interface in the Genius I/O ecosystem.

- IC660BBD – Related analog/digital mix block to support mixed I/O strategies.

- IC698CMM014 – Cross-platform accessory module in GE’s broader control system lineup.

- IC690BRM017 – Older-generation relay block sharing calibration and maintenance workflows.

- IC697ALG708 – Analog/digital module in legacy GE architectures with compatible integration methods.

- Installation Notes & Maintenance Best Practices

Prior to installation, confirm cabinet dimensions accommodate the module’s form factor and ensure adequate space for ventilation and service access. Verify a solid grounding scheme and clean backplane contacts to prevent intermittent faults; check for bent pins and ensure correct alignment during seating. Plan for the cumulative heat load in multi-module racks and confirm sufficient airflow paths to avoid hot spots. During commissioning, document the channel mappings, and test each output channel with a known-load to confirm correct switching and isolation. For maintenance, establish quarterly visual inspections focusing on relay contacts, terminal cleanliness, and wiring torque at the field terminations. Schedule firmware or hardware revisions in a controlled test rack before field deployment if updates are released, and keep spare relay blocks on hand to minimize downtime. Use diagnostic indicators to monitor coil resistance, contact wear, and any unusual heating. The IC660BBR101N benefits from disciplined preventive maintenance that aligns with other Genius I/O modules, ensuring consistent reliability and rapid fault isolation in live environments.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626