Description

What This Product Solves

In complex industrial automation systems, discrete control reliability is non-negotiable. The GE IC660BBD101 addresses one of the most persistent issues engineers face — dependable, noise-immune digital input and output handling in distributed I/O networks. Whether in a manufacturing plant, refinery, or power facility, control engineers often contend with field wiring noise, long cable runs, and mixed load types that challenge signal integrity and control timing. This module was designed to solve exactly those challenges.

Part of GE’s Genius I/O family, the GE IC660BBD101 combines input and output capability in one rugged module, providing flexible configuration for real-world automation needs. Its design reduces the number of modules required in a system while maintaining high reliability and diagnostic transparency. It’s built to withstand electrical interference, temperature swings, and continuous switching cycles — all common in demanding process control environments.

For users modernizing legacy systems or expanding existing Genius Bus networks, the GE IC660BBD101 ensures seamless compatibility and long-term stability. It keeps discrete control logic tight, responsive, and consistent, allowing OEMs and maintenance teams to focus on process optimization rather than troubleshooting erratic I/O behavior. In short, this module helps maintain system stability, reduce downtime, and sustain high-performance control even in electrically harsh conditions.

How the Product Works & Fits into a System

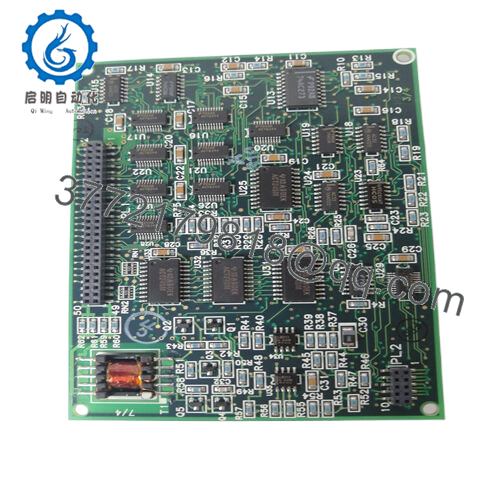

The GE IC660BBD101 is a 32-point combined I/O block that interfaces field devices directly to the Genius I/O network. It contains both input and output circuits, each capable of handling 24 VDC discrete signals, allowing one compact block to monitor sensors while simultaneously driving actuators. The module communicates with a controller over the Genius bus, transmitting I/O updates and receiving commands in real time.

Within the automation hierarchy, the GE IC660BBD101 operates at the field-level of the control stack, connecting limit switches, pushbuttons, proximity sensors, and pilot lights to higher-level PLCs or distributed control systems. Genius blocks like this one exchange data cyclically with the controller, providing deterministic I/O timing that aligns with the system scan cycle.

This module also supports extensive built-in diagnostics — open-wire detection, short-circuit protection, and per-channel status indicators — enabling quick troubleshooting and enhanced uptime. The Genius I/O network supports redundancy and distributed intelligence, meaning the GE IC660BBD101 can continue local operation or retain last-state outputs even during temporary communication interruptions. It’s an intelligent, compact I/O node that simplifies cabinet layouts and wiring complexity while maintaining the robust communication that GE systems are known for.

- IC660BBD101

Technical Highlights Summary

| Specification | Details |

|---|---|

| Model Number | IC660BBD101 |

| Brand | GE (General Electric) |

| Type | 32-Point DC Input/Output Block |

| Input/Output Voltage | 24 VDC (nominal) |

| Operating Temp Range | 0 °C to +60 °C |

| Mounting Style | Panel or DIN Rail |

| Dimensions | Approx. 230 mm W × 70 mm H × 50 mm D |

| Weight | ~1.0 kg |

| Interface/Bus | Genius I/O Bus |

| Compliance | CE, UL, cUL, RoHS |

| Supported Protocols | Genius Serial Bus |

| Typical Power Draw | 150 mA @ 24 VDC |

Real-World Benefits

Choosing the GE IC660BBD101 gives engineers a combination of versatility and durability that’s rare in compact I/O blocks. Its dual input/output design reduces hardware count, wiring complexity, and configuration overhead. By combining signal types in one module, it helps streamline cabinet design and field installation — an advantage for OEMs building modular equipment or retrofitting older control panels.

The block’s diagnostics and protection features are engineered for operational confidence. Built-in fault detection ensures that wiring issues are identified before they become downtime events. With solid-state outputs and optically isolated channels, the GE IC660BBD101 ensures long-term performance even in environments with inductive loads and electrical noise.

For maintenance teams, the visible LED indicators and integrated test features allow quick verification of signal states without removing field wiring. This practical, service-friendly design reduces mean time to repair (MTTR) and simplifies preventive maintenance routines. When combined with the Genius network’s distributed intelligence, the GE IC660BBD101 contributes to a resilient, low-maintenance control infrastructure that’s engineered for sustained productivity.

Typical Use Cases

The GE IC660BBD101 is used extensively in process control environments, manufacturing cells, and continuous-duty operations that demand reliable DC signal handling. In power generation and water treatment plants, it’s deployed to control pumps, valves, and indicators from field locations while maintaining deterministic bus communication with central PLCs.

In automotive and packaging lines, where high-speed sensor feedback and actuator control are critical, the GE IC660BBD101 ensures rapid I/O response without network lag. It also performs well in harsh industrial environments such as refineries or steel plants, where electrical noise and vibration can degrade standard I/O performance.

Across industries, this block plays a vital role in distributed control systems — ensuring critical system uptime, simplifying wiring runs, and keeping automation hardware reliable under continuous operation.

Compatible or Alternative Products

IC660BBD120 – Isolated version for applications requiring independent channel isolation

IC660BBD025 – Sink-type DC input block for signal-only applications

IC660BBD022 – Source-type DC input module compatible with standard Genius networks

IC660TBD025 – Terminal assembly for wiring and field connection

IC660BBA026 – Analog I/O block for mixed-signal process control

IC660ELB905 – Genius Bus interface for controller integration

IC660BBD110 – High-current output version for inductive or relay-driven loads

IC660BRD025 – Replacement terminal board for maintenance or retrofit use

Setup Notes & Maintenance Insights

Before installation, confirm that the GE IC660BBD101 is configured for the correct node address on the Genius network and that the bus length and termination comply with system design limits. Verify adequate 24 VDC field power supply capacity and maintain clean grounding to prevent noise coupling through shared conductors. Mount the block securely on a stable panel or DIN rail with sufficient spacing for ventilation and wiring clearance.

During commissioning, each channel can be tested individually using built-in test switches and visual LED confirmation. Periodic inspections should include checking terminal screw torque, verifying LED indicators, and ensuring the module’s enclosure remains free of dust and moisture. Firmware configuration parameters can be reviewed through GE’s configuration software or handheld Genius tools.

Routine maintenance typically involves annual verification of communication integrity and inspection of field wiring. With minimal moving parts and sealed solid-state components, the GE IC660BBD101 provides long operational life with little maintenance intervention required.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626