Description

In high-availability process control and large-scale factory automation systems, the moment a single digital input or output point fails to register correctly, the consequences cascade fast: a motor runs when it should be stopped, an emergency stop circuit is ignored, or a critical valve stays closed during startup. When you’re dealing with hundreds or thousands of I/O points spread across a plant, the weak link is rarely the PLC itself — it’s the low-density, non-redundant 24 VDC blocks that force you to crowd panels, run excessive home-run wiring, and live with single points of failure. The real pain comes when a single card failure takes thirty-two safety-related inputs offline, triggering an unplanned trip that costs six figures an hour.

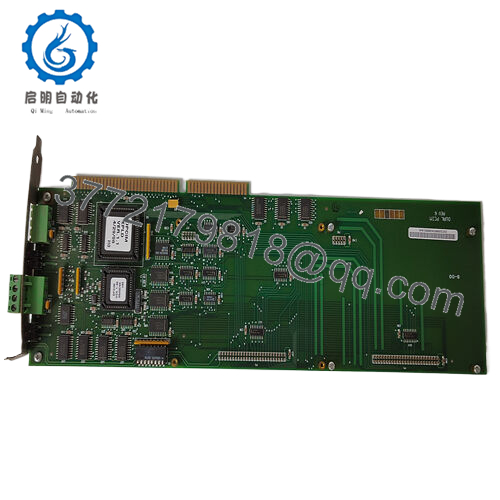

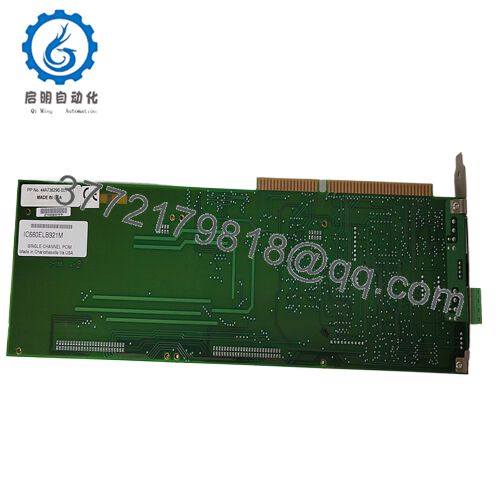

The GE IC660BBD025 was engineered specifically to eliminate that vulnerability. This Genius Block 5/12–24 VDC 32-point sinking source/sink load I/O module delivers high-density, individually isolated discrete I/O with built-in diagnostics and hot-swap capability directly on the Genius bus — the same bus that powered GE’s 90-70 and Series Six systems for decades and still runs in thousands of plants today. Each of the 32 circuits can be configured independently as input or output (sinking input, sourcing output), so one block can simultaneously monitor limit switches, pushbuttons, and 24 V pilot devices while driving solenoids, relays, or indicator lamps — all without external interposing terminals. Because every circuit is optically isolated to 1500 V and the block itself supports electronic over-temperature and short-circuit protection with automatic retry, the GE IC660BBD025 routinely survives the electrical abuse that kills conventional terminal-style I/O in less than a year.

In redundancy-configured Genius networks, dual-bus operation and selectable input filtering (1–100 ms) give you the confidence that a single cable cut or noisy weld cell won’t blind the controller. For plants that standardized on Genius I/O in the 1990s and 2000s and refuse to accept forced obsolescence, the IC660BBD025 remains the gold-standard drop-in replacement that keeps the original bus architecture alive while actually improving diagnostics and density.

The GE IC660BBD025 sits physically on the machine or in a remote marshalling cabinet and communicates over the dual-redundant Genius LAN at 153.6 kbaud — the same noise-immune, token-passing protocol that has logged billions of runtime hours worldwide. Configuration is handled through Hand-Held Monitor or VersaPro/Proficy Machine Edition: you simply assign each circuit as input or output, set filter time, enable output pulse-test or hold-last-state, and decide whether to use BSM (Bus Switching Module) redundancy. The block draws its logic power from the bus itself while field power (5–24 VDC for inputs, 12–24 VDC for outputs) is fed separately through robust compression terminals that accept up to 12 AWG wire.

On-board diagnostics are comprehensive: open-wire, short-circuit, failed-switch, overload, and loss-of-field-power are reported per-circuit to the PLC fault table and displayed on the block’s LEDs in plain language. Outputs can be individually pulse-tested without affecting the process, and inputs feature configurable thresholds and debounce — invaluable when reading directly off inductive proximity sensors in high-vibration environments. Because Genius blocks are truly distributed, the IC660BBD025 can live up to 7500 feet from the controller on a single twisted-pair cable, dramatically reducing home-run wiring costs compared to parallel backplane systems.

- IC660BBD025

- IC660BBD025

| Specification | Details |

|---|---|

| Model Number | IC660BBD025 |

| Brand | GE (now Emerson) |

| Type | 32-Point Configurable Sink/Source I/O Block |

| I/O Count | 32 circuits (individually configurable) |

| Input Voltage | 5–24 VDC (sinking) |

| Output Voltage | 12–24 VDC sourcing, 2 A per point (surge 10 A) |

| Operating Temp Range | 0 °C to +60 °C |

| Mounting Style | Direct panel or optional baseplate |

| Dimensions (W×H×D) | 224 mm × 90 mm × 224 mm |

| Weight | 1.8 kg |

| Interface/Bus | Genius dual redundant LAN (153.6 kbaud) |

| Compliance | CE, UL, Class I Div 2, ATEX Zone 2 |

| Supported Protocols | Native Genius protocol |

| Typical Power Draw | 9 W bus + field load |

Specifying the GE IC660BBD025 means you’re choosing I/O that was literally built for 20+ year service in the toughest environments GE ever served. The 2 A continuous (10 A inrush) sourcing outputs drive real plant loads — contactors, brake coils, stack lights — without burning contacts or requiring interposing relays, while individual electronic fusing and auto-retry keep a single fault from taking the whole block offline. Isolation and noise immunity are so good that blocks routinely live inside welding cells or next to 1000 hp medium-voltage drives without missing a beat.

Maintenance shifts from chasing mysterious faults to predictive replacement: the Hand-Held Monitor or PLC fault table tells you exactly which circuit has an issue before the process even notices. Hot insertion/removal under power (when used with Genius redundancy) means you can swap a block during full production without a single I/O blip. Plants that track MTBF consistently report Genius blocks exceeding 25 years in continuous operation — numbers that make the IC660BBD025 one of the lowest total-cost I/O solutions still available in 2025.

You’ll find the GE IC660BBD025 in steel mills sequencing overhead cranes where a missed limit switch equals catastrophe, in automotive assembly plants reading weld-gun proximity sensors at 8 ms scan rates, and in power-generation auxiliary systems monitoring breaker status and driving annunciators across campus-wide Genius networks. Water-treatment filter plants use them for valve feedback and pump-start circuits that must survive lightning-induced surges, while oil & gas compressor stations rely on the Div 2/Zone 2 rating and redundant bus to maintain anti-surge control without single-point failures. In every case the requirement is absolute confidence in discrete signal integrity under harsh electrical and environmental conditions — precisely what the IC660BBD025 has delivered flawlessly for three decades.

IC660BBD020 – 24 VDC source input block (input-only version)

IC660BBD021 – 24 VDC sink output block (output-only, higher current)

IC660BBD022 – 5/12–24 VDC source input block, 32-point

IC660BBD024 – 24 VDC 32-point current-source output block

IC660BBD026 – 5/12–24 VDC 32-point sinking input block

IC660BBD101 – 115 VAC low-leakage I/O block (same family, AC voltage)

IC660BBD110 – 115 VAC 16-point input block

IC660TBD022 – Terminal assembly replacement for field wiring

Before installing the GE IC660BBD025, confirm your Genius bus is terminated correctly at both ends (75 Ω on each line) and that you’re using Belden 9182 or equivalent dual-shielded cable for runs over 500 feet. Verify field power is clean 24 VDC (18–30 V) capable of supplying the total load — the block itself draws only 9 W from the bus, but outputs can pull tens of amps when fully loaded. Set the block address with the thumbwheels (1–31) before applying power, and always perform a bus continuity test with the HHM before going live. Leave at least 50 mm side clearance if ambient exceeds 50 °C.

In service, maintenance is largely visual: the diagnostic LEDs spell out faults in plain English, and the Hand-Held Monitor can force outputs or read individual circuit status in seconds. Once a year, cycle field power while watching the fault table to confirm no latent wiring issues have developed. Terminal blocks are removable under power (with caution) for fast rewiring, and spare electronics assemblies (EBA025) allow five-minute swaps without disturbing field wiring. Stocking one or two spare IC660BBD025 units per site remains standard practice in plants that refuse to gamble critical uptime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626