Description

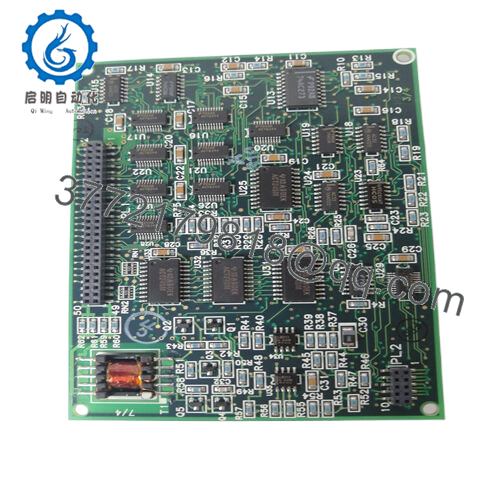

In the high-stakes realm of industrial automation, where every I/O signal must deliver unerring precision to keep processes humming, the challenge often boils down to bridging field devices with central controls without introducing vulnerabilities. Engineers in process control setups routinely face issues like sensor signal dropouts from wiring faults, overloads in mixed input/output configurations, or compatibility headaches with legacy two- and three-wire devices—problems that erode system stability and inflate downtime costs. Enter the GE IC660BBD022V, a robust 16-circuit sourcing I/O block from GE’s Genius series, tailored for distributed architectures that demand high reliability in handling discrete signals. This module tackles the need for flexible, field-hardened I/O management, ensuring seamless integration of proximity sensors, relays, and actuators into your PLC or PAC ecosystem.

Consider a typical scenario in a bustling assembly line, where vibration and dust play havoc with sensor readings, or a water treatment plant where fluctuating loads require instant response from valve controls to avoid overflows. The GE IC660BBD022V shines here, offering configurable circuits that adapt on the fly to input monitoring or output driving, all while providing built-in diagnostics to catch open-wire faults before they cascade. In broader industrial automation landscapes, it supports the push for modular expansions without ripping out existing cabling, making it indispensable for retrofits in aging facilities. Its emphasis on high reliability—through noise-immune sourcing and fault-tolerant bus communication—means operators spend less time chasing ghosts in the wiring and more on optimizing throughput. For teams weighing options, essentials like its 24 VDC focus and 2 A per-circuit capacity directly influence scalability, while Genius protocol compatibility ensures it slots into Series 90-30 or 90-70 systems without custom middleware. By addressing these real-world friction points, the GE IC660BBD022V empowers resilient process control, turning potential bottlenecks into reliable data streams that underpin predictive operations and regulatory compliance.

When deploying the GE IC660BBD022V in your automation stack, envision it as the versatile nerve center that connects the plant floor to your core logic processors, processing discrete signals with the finesse needed for dynamic environments. This Genius I/O block houses 16 independent circuits, each programmable via handheld monitor or PC software as either inputs for capturing states from solid-state sensors or outputs for energizing solenoids and indicators. It communicates over the Genius serial bus, linking directly to bus controllers like the IC660/693BEM731 in Series 90-70 PLCs or IC693BEM331 in 90-30 setups, where it occupies a remote drop position for decentralized I/O distribution.

In the overall architecture, it sits at the edge layer, conditioning 24 VDC signals from two- or three-wire field devices before relaying them upstream to CPUs for decision-making, or receiving commands to drive loads downstream. Redundancy is baked in through bus failover options, allowing seamless handoff if a cable snaps, while onboard diagnostics—accessible via LED indicators or bus queries—flag issues like overcurrent or short circuits in real time. It supports no specific higher-layer protocols beyond Genius, but that simplicity aids integration with HMIs for at-a-glance status views or third-party gateways for hybrid networks. Think of it bridging the gap in a multi-drop bus topology: sensors feed clean on/off data to the block, which aggregates and timestamps it for the controller, enabling scan times under 10 ms in time-critical loops. For practical fit, pair it with terminal bases for hot-swappable maintenance, ensuring the GE IC660BBD022V enhances rather than complicates your I/O subsystem, fostering an architecture that’s as expandable as it is dependable.

| Specification | Details |

|---|---|

| Model Number | IC660BBD022V |

| Brand | GE (Emerson) |

| Type | 16-Circuit Sourcing Discrete I/O Block |

| Input Voltage | 24 V DC |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Panel Mount |

| Dimensions | 8.83 x 3.50 x 3.94 in (22.44 x 8.89 x 10.00 cm) |

| Weight | 4 lbs (1.81 kg) |

| Interface/Bus | Genius Serial Bus |

| Compliance | CE, UL, CSA |

| Supported Protocols | Genius |

| Typical Power Draw | 68.8 W (at 2 A load) |

- IC660BBD022V

- IC660BBD022V

Bringing the GE IC660BBD022V into your setup yields dividends in operational steadiness, where engineered durability translates to fewer surprises during peak production. Its sourcing design actively powers field devices, which stabilizes signal integrity in noisy environments and cuts down on ground-loop errors that plague passive systems—ultimately ensuring control loops hold steady even as ambient conditions shift, preserving the accuracy your processes depend on.

This reliability extends to maintenance rhythms, as the module’s self-diagnostics surface wiring anomalies early, slashing troubleshooting time and letting technicians address root causes rather than symptoms. Performance consistency shines in variable-duty cycles; outputs handle 10 A inrush without falter, supporting everything from intermittent indicators to steady-state motors, which means your system scales without recalibrating for every tweak. Integration ease is another quiet win—Genius bus addressing simplifies drop additions, reducing engineering overhead for expansions that might otherwise demand full rewires.

Over the long haul, choosing this block fosters a leaner footprint: lower power ripple keeps ancillary cooling needs minimal, while its compatibility with legacy sensors avoids the scrap-and-replace costs of modernizing piecemeal. It’s about crafting a control environment where high reliability isn’t a luxury but the baseline, enabling teams to chase efficiencies like tighter cycle times instead of firefighting faults.

The GE IC660BBD022V proves its mettle in sectors craving uninterrupted discrete control, such as automotive assembly lines where it monitors limit switches and drives pneumatic clamps amid relentless part flows, ensuring critical system uptime in fast-paced, high-volume environments. In wastewater management process control plants, it interfaces with level sensors and pump starters in damp, corrosive zones, delivering responsive on/off commands that maintain flow balances without signal glitches from moisture ingress.

Food and beverage processing offers another fit, with the module deployed in hygienic washdown areas to track conveyor position via proximity detectors and actuate fillers—its 2/3-wire sensor compatibility handles diverse legacy gear while supporting rapid data cycles for batch synchronization. Across these applications, from power distribution substations to pharmaceutical packaging, the GE IC660BBD022V upholds high reliability under harsh conditions, powering the fault-tolerant I/O that keeps operations compliant and productive.

IC660BBD020 – Dual-voltage (24/48 VDC) variant for broader legacy compatibility

IC660BBD021 – Sink I/O counterpart for grounded-load applications

IC660BBD023 – 24 VDC sink version with enhanced fault monitoring

IC660BBD120 – High-speed discrete block for counter/timer needs

IC660BBA104 – Relay output alternative for AC inductive loads

IC660/693BEM731 – Bus controller for Series 90-70 integration

IC660/693BEM331 – Bus interface module for Series 90-30 expansions

IC660BSM021 – Bus switching module for redundant network paths

As you prepare to integrate the GE IC660BBD022V, start by confirming Genius bus drop addressing aligns with your controller’s map—mismatches can lock out communications, so use the handheld monitor for a pre-install scan. Verify panel space allows the standard 1.5-inch side clearance and 3-inch top/bottom ventilation to manage heat from full-load runs; overcrowding invites thermal throttling. Power-wise, ensure a stable 24 VDC supply with at least 3 A headroom, and test terminal strip torque to 7-9 in-lbs to prevent loose connections that mimic faults. Firmware isn’t user-upgradable here, but cross-check the electronics assembly revision against your system’s protocol version during bench validation.

In daily upkeep, keep it straightforward: monthly visual sweeps for terminal corrosion or dust buildup in exposed sites, paired with bus polls to clear any latched diagnostics. Quarterly, cycle all circuits with a dry run—toggle inputs via software and measure output voltages to spot drift early, avoiding escalation to full outages. LED checks during rounds provide instant health cues, like steady green for bus OK or flashing for circuit alarms, and if a channel flags open-wire, isolate it via config to isolate without halting the drop. This regimen, grounded in the module’s inherent diagnostics, keeps the GE IC660BBD022V as a low-touch asset, letting you allocate resources to strategic tweaks rather than routine heroics.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626