Description

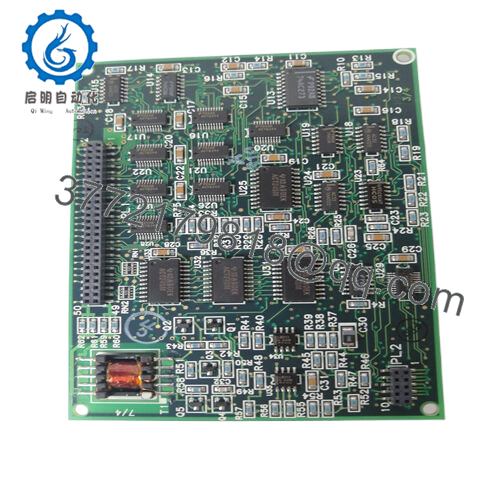

In industrial automation, where sourcing precise analog inputs from thermocouples or RTDs in noisy, distributed environments can make or break temperature-critical processes, dealing with signal drift, grounding issues, or cumbersome wiring often leads to inaccurate readings and unplanned maintenance. Imagine a steel mill monitoring furnace zones where even a 1°C offset triggers scrap or safety shutdowns, or a food processing plant tracking pasteurization temps across remote sensors—any loss of channel isolation risks cross-talk and compliance failures. The GE IC660BBD022 steps in as a 16-channel thermocouple input block from the Genius I/O family, delivering reliable, isolated mV-level signals directly to your PLC bus without intermediate converters, ensuring high-resolution data in demanding setups.

This block becomes essential in high-reliability industrial automation when expanding legacy Series 90 or RX3i systems with field-mounted I/O, such as retrofitting paper mills for denser sensor networks without pulling new home runs, or deploying in oil platforms where explosion-proof housings and bus redundancy counter harsh vibrations. Engineers choose the GE IC660BBD022 for scenarios needing configurable cold-junction compensation and open-wire detection per channel, like batch reactors in chemicals requiring Type J/K/T inputs with linearization to maintain recipe integrity. It supports system stability through Genius bus fault tolerance—hot-swappable without disrupting the loop—and diagnostics that report underrange/overrange or burnout directly to the controller. In process control environments prioritizing I/O signal accuracy, its role in reducing noise via 250VAC isolation per channel can’t be overstated, incorporating SEO keywords like Genius I/O thermocouple block, 16-channel source input, high reliability automation, and distributed temperature monitoring for applications demanding uptime in extended bus lengths up to 7500 feet. Whether handling slow-response thermocouples in kilns or fast transients in test stands, the GE IC660BBD022 provides the modular integration needed for scalable, fault-resilient data acquisition without overcomplicating your architecture.

Dropping the GE IC660BBD022 onto a Genius bus positions it as a smart field device, connecting via dual terminals for handheld monitor (HHM) or bus switching module (BSM), with each of its 16 channels accepting mV signals from Types J, K, T, E, B, R, S, or N thermocouples—auto-ranging ±25mV to ±100mV while applying internal CJC via a built-in sensor. It interfaces with host controllers like IC697 CPUs or third-party PLCs over the redundant 153.6 kbps Genius protocol, reporting scaled data in engineering units or raw counts.

In the automation stack, it’s at the distributed I/O layer, daisy-chained with other Genius blocks for up to 30 devices per bus, supporting block-level redundancy by mirroring configs across dual cables—no single fault kills the loop. Diagnostics flow intuitively: onboard LEDs for block OK and bus status, plus per-channel fault bits accessible via HHM or software for open thermocouple or out-of-range alerts, no need for loop checks during runtime. It interacts via configurable inputs—select sink/source though source-only for thermocouples—and holds last states on bus loss, with optional hold-last or default modes. For broader systems, pair with BSM for loop isolation or IC66* terminals for wiring ease. This setup avoids centralized I/O bottlenecks, enabling remote mounting near sensors to cut cable costs—the GE IC660BBD022 configures via HHM pushbuttons or VersaPro software, scales seamlessly in process control, and adapts to mixed block types without protocol headaches.

- IC660BBD022

- IC660BBD022

| Specification | Details |

|---|---|

| Model Number | IC660BBD022 |

| Brand | GE (Emerson) |

| Type | 16-Channel Thermocouple Input Block |

| Input Voltage | 5 VDC (bus), 115/230 VAC or 125 VDC optional |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Panel or DIN rail (with terminal assembly) |

| Dimensions | Approx. 224 x 90 x 224 mm (block only) |

| Weight | 1.8 kg (block), 4 kg with terminals |

| Interface/Bus | Genius I/O Bus (dual terminals) |

| Compliance | CE, UL, CSA, Class 1 Div 2 |

| Supported Protocols | Genius (153.6 kbps, redundant) |

| Typical Power Draw | 6 W (block), 9 W max |

Choosing the GE IC660BBD022 means fielding thermocouple inputs engineered for precision in real-world grime, where 1500V isolation per channel blocks ground loops that plague non-isolated alternatives, delivering ±0.5°C accuracy post-linearization to keep processes like annealing or sterilization within spec without constant recalibration. This consistency curbs quality deviations, directly boosting yield in temperature-sensitive runs.

Integration reduces engineering overhead: Genius bus daisy-chaining means adding blocks mid-loop without rewiring controllers, while HHM portability speeds channel setups in the field—no laptop tethering required. Maintenance efficiency rises with per-channel diagnostics flagging burned-out elements instantly, plus hot-swap capability that swaps blocks live on redundant buses. Built for long-term performance in damp or dusty enclosures, its rugged electronics unit and terminal assembly ensure sustained reliability without contact pitting, turning distributed sensing from a liability into an asset that supports sensor expansions or bus extensions effortlessly.

The GE IC660BBD022 proves vital in temperature-dense applications, such as power plants monitoring boiler tubes across Genius loops for early leak detection, providing fast data cycles amid steam and vibration for critical system uptime. Chemical reactors deploy it for multi-zone catalyst beds, leveraging open-wire alerts in explosive atmospheres requiring continuous, isolated monitoring.

Food and beverage lines use it in ovens or freezers, handling Type T inputs with CJC for traceability in washdown process control environments used in pharmaceuticals or high-volume drying where faults can’t interrupt validated cycles. Across these, the GE IC660BBD022 excels in harsh conditions with modular bus scaling for operational resilience.

IC660BBD020 – 16-channel RTD sibling for resistance-based sensors

IC660BBD024 – 4-20 mA source analog input for current loops

IC660BBD101 – Discrete 115 VAC input block for valve feedback

IC660BBD120 – High-density thermocouple variant with extended types

IC66TBD120 – Terminal assembly pair for field wiring

IC660BSM021 – Bus switching module for redundancy implementation

IC660HHM501 – Handheld monitor essential for config/diagnostics

IC697BEM731 – Genius bus controller for Series 90-70 hosts

Before mounting the GE IC660BBD022, verify bus termination at ends—115 ohm resistors across terminals if not using active BSM—and confirm power sourcing from the bus or auxiliary to avoid voltage drops over long chains. Pre-configure thermocouple types via HHM offline to prevent mismatch faults on first scan, and shield wiring pairs twisted with grounds at one end only for noise rejection; check CJC sensor location clear of heat sources. Label channels meticulously for quick thermocouple swaps, and test redundancy by forcing a cable cut pre-commission.

Ongoing maintenance stays field-focused: weekly HHM sweeps per block catch drifting offsets or open channels early. Monthly, retorque terminals in vibrating plants, and simulate burnouts quarterly to validate fault reporting. Annually, clean electronics vents gently and recalibrate CJC against ice bath standards, archiving configs to spare HHM. These habits address common thermocouple fragility or bus noise proactively, keeping inputs accurate in multi-block loops.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626