Description

In most industrial automation environments, the real bottleneck to uptime is rarely the PLC itself—it’s the dozens or hundreds of 24 V DC solenoids, motor contactors, limit switches, and pilot lights that tie field devices to the controller. When a single sinking output driver fails closed or a sourcing input channel drifts into an undefined state, the result is usually an immediate line stop, a safety trip, or a batch reject. Even worse, many legacy I/O systems force you to power-cycle an entire rack just to clear a latch fault or replace a blown fuse, turning a 30-second fix into a 30-minute outage.

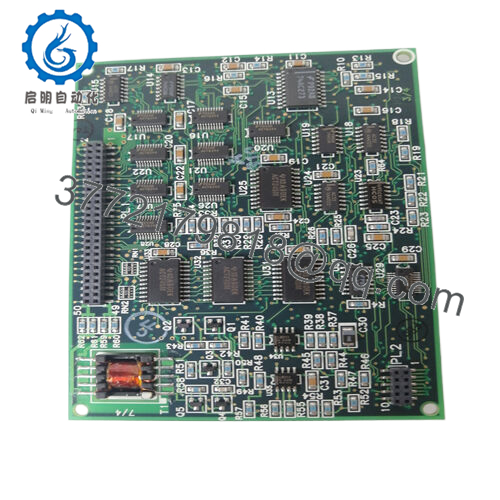

The GE IC660BBD020 24 V DC Source I/O Block was designed precisely to eliminate these pain points. This 32-point (16 inputs / 16 outputs) Genius block delivers individually isolated, electronically protected sourcing outputs and optically isolated sinking inputs in a single rugged brick that mounts right where the action is—on the machine frame, in cable tray, or inside a motor control center. Engineers specify the IC660BBD020 when they need fast, deterministic response from 24 V field devices without the fragility of centralized racks or the cost of running a separate homerun for every valve and sensor. Instead of dozens of individual wires snaking back to the panel, you drop one dual-twisted-pair Genius bus and get 32 high-reliability I/O points with built-in diagnostics and hot-swap capability.

The block appears on the Genius network as a standard 32-point device and talks natively to Series 90-30, 90-70, PACSystems RX3i, or any host that understands Genius protocol. Each output can source 2 A continuously (with 8 A per group limit) and includes electronic over-temperature shutdown plus individual open-load and short-circuit detection. Inputs are 24 V DC sinking with selectable 5/10/20 ms filtering, so you can tune noise rejection without sacrificing response on fast proximity switches. Diagnostics are reported per-point: open wire, shorted load, failed output FET, and input state mismatch—all visible both on the block’s LEDs and in the controller fault table, which dramatically cuts mean-time-to-repair.

- IC660BBD020

- IC660BBD020

| Specification | Details |

|---|---|

| Model Number | IC660BBD020 |

| Brand | GE (now Emerson) |

| Type | 24 V DC Source I/O Block, 16 in / 16 out |

| Input Voltage | 18–30 V DC (24 V nominal) |

| Operating Temp Range | 0 °C to 60 °C (full load, no derating) |

| Mounting Style | Panel mount with IC660TBA020/021 terminals |

| Dimensions (W×H×D) | 224 × 90 × 224 mm (block only) |

| Weight | 1.8 kg (block) + 1.4 kg terminal assembly |

| Interface/Bus | Genius LAN (153.6 kbps standard) |

| Compliance | CE, UL, CSA, Class I Div 2 A–D |

| Supported Protocols | Genius I/O |

| Typical Power Draw | 11 W (idle) to 35 W (all outputs loaded) |

Choosing the IC660BBD020 gives you confidence that a single stuck valve coil or a loose proximity switch won’t cascade into hours of lost production. The electronic output protection means you rarely blow a fuse—short the output and the driver simply shuts down until the fault is cleared, then automatically recovers. Maintenance technicians can replace the entire electronics assembly in under two minutes while the bus and the remaining 31 points stay live. Over the life of a typical packaging line or assembly machine, plants routinely see 60–80 % fewer I/O-related trips after converting centralized terminal boards to distributed IC660BBD020 blocks.

The IC660BBD020 is everywhere you see high-density 24 V DC devices in harsh or space-constrained areas: automotive assembly (weld cells, transfer lines), material handling systems (conveyors, AS/RS cranes), food & beverage packaging lines, and water-treatment plants. In body shops, multiple blocks live inside weld-cell pedestals controlling hundreds of clamp and tip-dress cylinders with zero downtime for output replacement. Bottling lines mount them directly above the filler valves, cutting cable runs by 70 % and eliminating the rats-nest of intermediate terminal strips that used to be the number-one failure point during washdown.

IC660BBD021 – Companion 24 V DC Sink I/O block (outputs sink instead of source)

IC660BBD022 – 24 V DC Source block with 5–10 ms input filtering for noisier environments

IC660BBD024 – 32-point 24 V DC Source block with higher 4 A per channel rating

IC660BBA020 – 4-channel 115 V AC / 24 V DC analog mixed block often used nearby

IC660BPM100 – Genius bus power monitor/feed module for long cable runs

IC660BRD024 – Redundant Genius bus controller for critical networks

IC660TBA020 – Current-version terminal base with improved clamp design

Before installation, verify that your 24 V supply is truly floating or negatively bonded—mixing source and sink blocks on the same common defeats isolation. Set the block address with the Hand-Held Monitor or Machine Edition before applying power; most sites reserve the lower addresses for discrete blocks to keep the scan orderly. Use the IC660TBA020 (or newer TBA021) terminal base—older gray bases have weaker clamps that loosen under vibration. Once a year, cycle power and watch the diagnostic LEDs for any latched faults; clearing them is as simple as toggling the “Clear Faults” command from the PLC.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626