Description

In water treatment facilities and chemical processing plants, the GE IC660BBA100 handles precise analog signal interfacing for level sensors, flow transmitters, and pressure transducers that feed into distributed control systems. Engineers deploy it across oil refineries, pharmaceutical batching lines, and power plant boiler controls where varying process conditions demand reliable voltage or current translation without introducing noise or drift. These environments often grapple with long signal runs amid electrical interference from motors and valves; the GE IC660BBA100 steps in to condition those signals for Genius I/O networks, enabling PLCs to maintain tight loop control on variables like pH, temperature, or tank fill rates used in industrial automation. In pulp mills or food processing, it supports multi-point monitoring of mixing tanks or conveyor speeds, where operators need instant visibility into deviations that could halt production. By converting raw transducer outputs into digital values over the Genius bus, it helps teams respond faster to excursions, cutting downtime in control systems applicable to continuous processes. The module shines in retrofit projects too, linking legacy sensors to modern hosts without full panel rewiring, a common pain point in brownfield upgrades.

Food and beverage packagers turn to the GE IC660BBA100 for dosing pumps and filler heads, ensuring consistent product quality amid steam cleaning cycles and washdowns. Its flexibility across voltage and current ranges matches diverse field devices, from 4-20 mA loops to bipolar signals, making it a go-to for sites blending old and new instrumentation. Maintenance crews value how it flags open wires or alarm limits right on the bus, streamlining diagnostics in sprawling MCC rooms where access is limited

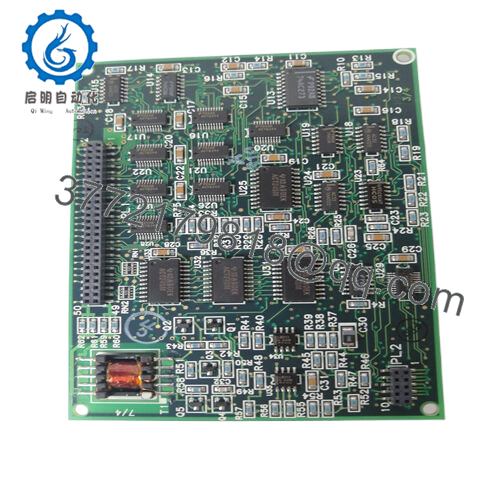

The GE IC660BBA100 functions as a rack-mounted analog I/O block within GE Fanuc’s Genius distributed I/O system, bridging field sensors and actuators to host PLCs or PCs over a high-speed serial bus. It features four independent input channels that digitize voltage or current signals via a shared 12-bit A/D converter, alongside two output channels driven by a 12-bit D/A for commanding valves or recorders. Positioned as a remote I/O node, the GE IC660BBA100 drops into standard Genius terminal bases, communicating via daisy-chained twisted-pair cabling that supports bus speeds up to 153.6 kbaud across hundreds of meters. This setup lets it integrate seamlessly into Series 90-70 or 90-30 architectures, where blocks poll each other for data without dedicated cabling to the CPU.

For integrators, the GE IC660BBA100 stands out by allowing per-channel scaling in engineering units directly at the block, reducing CPU overhead and simplifying HMI tagging. It holds outputs at last value or defaults during comms loss, preventing wild swings in controlled processes—a critical safeguard in safety interlocks or batch recipes. Backward compatibility with Phase A blocks like IC660CBA100 eases migrations, while configurable filters tame noisy signals from vibrating machinery.

Operators running the GE IC660BBA100 count on its 4 ms update rate for inputs, fast enough to track dynamic processes like compressor surges or reactor feeds without lag. Accuracy holds at 0.2% typical across ranges, with thermal drift under 10 PPM/°C ensuring stability through seasonal swings in control rooms. The shared converter design optimizes cost without sacrificing channel independence, and diagnostics like underrange or high alarms route straight to the host for proactive alerts.

Hardware-wise, the GE IC660BBA100 mounts via rear screws into DIN rail assemblies, its compact footprint fitting tight enclosures while LEDs signal unit health and I/O status at a glance. Block-to-block isolation at 1500V RMS guards against ground faults common in shared cabinets, and 60 dB common-mode rejection shrugs off line noise. Outputs drive up to 2000 ohms in voltage mode or handle 300 ohms current loads, suiting most actuators without external amplification.

In mixed-protocol plants, the GE IC660BBA100 plays well with Modbus or Ethernet gateways via the Genius bus, exposing analog data to DCS overlays. Long-term, its 0-60°C operating range and vibration tolerance suit conveyor bays or pump houses, with open-wire detection catching cable failures early.

- IC660BBA100

- IC660BBA100

| Parameter | Value |

|---|---|

| Model | IC660BBA100 |

| Brand | GE Fanuc (Emerson/GE) |

| Product Type | Analog I/O block, 4 inputs / 2 outputs |

| Power Supply | 115 VAC nominal (98-132 VAC operating), 47-63 Hz |

| Operating Temperature | 0 to 60°C (32 to 140°F) |

| Storage Temperature | -40 to 100°C (-40 to 212°F) |

| Mounting | Rear screw mounting on DIN rail terminal base |

| Dimensions | 8.83 in H x 3.34 in W x 3.91 in D (22.44 x 8.48 x 9.93 cm) |

| Weight | 4 lbs (1.8 kg) |

| Interfaces | Genius bus (twisted pair), screw terminals for field wiring (12 AWG) |

| Resolution | 12-bit + sign for inputs/outputs |

| Input Ranges | 0-10 VDC, ±10 VDC, ±5 VDC, 0-5 VDC, 4-20 mA |

| Output Ranges | 0-10 VDC, ±10 VDC, ±5 VDC, 0-5 VDC, 4-20 mA |

| Isolation | 1500 V RMS block-to-block |

| Heat Dissipation | 6 Watts |

IC660BBA020 – DC-powered variant (24/48 VDC) for sites avoiding AC supplies, shares identical I/O ranges and performance.

IC660CBA100 – Phase A predecessor, limited to Series Six/Five PLCs but functionally similar for legacy Genius drops.

IC660EBA020 – Electronic baseplate for expanding I/O in dense racks alongside IC660BBA100 blocks.

IC660TSA020 – Terminal strip assembly paired with IC660BBA100 for field wiring in hazardous locations.

IC660BBD100 – High-density analog block with more channels, used when IC660BBA100 point count falls short.

IC660BBA024 – RTD/thermocouple input companion, complements voltage/current handling in sensor-heavy loops

IC660ELB915 – Bus controller interface for linking Genius blocks like IC660BBA100 to Series 90-30 CPUs.

Position the GE IC660BBA100 away from high-voltage trays during layout, allowing 2-3 inches clearance for wiring bends and heat flow in the terminal base. Ground shields at the block only to avoid loops, and torque terminals to spec—loose connections amplify noise on 4-20 mA loops. Pre-configure baud rates and block addresses via handheld programmer to match the bus, verifying polarity on power leads since reversed phases disable the unit silently.

Routine checks on the GE IC660BBA100 involve scanning host diagnostics for alarm counters every shift in critical loops, plus quarterly visual scans for terminal corrosion or LED flickers signaling filter saturation. Cycle power annually to self-test dropout handling, and log scaling values before firmware tweaks to PLC logic. If open-wire faults recur, swap in shielded cable and add ferrites—common fixes that extend service life beyond a decade.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626