Description

Real-World Use & Application Scenarios

Factories running GE Series Six PLCs or Series 90 systems grab GE IC647WMI620 to link rugged industrial controllers with PS/2 Workmaster PCs for operator interfaces, troubleshooting, and data logging during 24/7 shifts where a comms dropout means stalled lines in bottling plants or assembly halls. This interface module thrives in environments like automotive stamping, pharmaceutical batching, and material handling warehouses, where vibration, EMI from motors, and dusty air challenge serial-parallel connections between PLC racks and supervisory workstations. Maintenance crews depend on it to pull diagnostics, upload ladder edits, or mirror HMI screens without halting processes, addressing downtime from legacy floppy transfers or unreliable RS-232 links in control systems.

In brownfield upgrades tying PLCs to early Windows NT setups, GE IC647WMI620 handles parallel data dumps and serial handshaking for CIMPLICITY or Workmaster software, keeping production flowing amid legacy hardware constraints. Engineers deploy it in used in industrial automation for scenarios demanding quick PC swaps or remote polling, like conveyor sequencing or tank farm monitoring where real-time trending spots pump stalls early. Applicable in control systems with mixed GE Fanuc gear, GE IC647WMI620 bridges gaps in radial networks, ensuring fault logs and setpoints sync reliably even under power blips or network noise

Product Introduction & Positioning

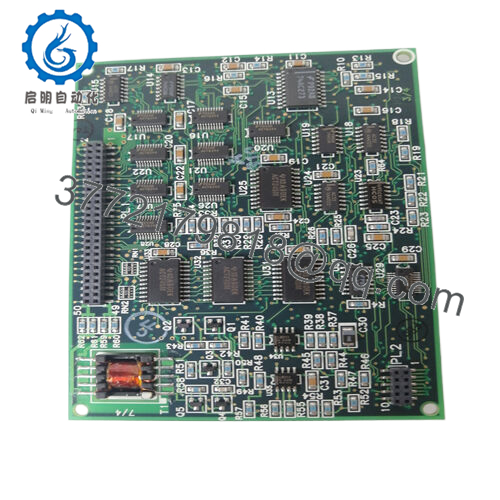

GE IC647WMI620 acts as a PS/2 Workmaster interface module for GE Fanuc Series Six and compatible PLC platforms, enabling parallel and serial communication between rack-mounted controllers and IBM PS/2-style PCs. It mounts in I/O slots or as a dedicated comms card, shuttling data at 500 KB/s for program transfers, status mirroring, and diagnostic sessions without tying up PLC scan times. Within the architecture, GE IC647WMI620 connects the core CPU—like a Series Six master—to front-end PCs running Workmaster II or similar, feeding process variables upward while accepting downloads securely.

Integrators position GE IC647WMI620 as a reliability booster for legacy expansions, with variants like IC647WMI620/RR or A/RR offering buffered handshaking for noisy floors. Its value shines in simplifying HMI builds, where one module handles printer ports, serial debugging, and parallel dumps, cutting cabling in tight panels. For sites standardizing on GE Fanuc, GE IC647WMI620 streamlines spares and training, evolving older systems toward Ethernet previews without full overhauls.

- IC647WMI620

Key Technical Features & Functional Benefits

GE IC647WMI620 delivers a parallel interface at 500 KB/s alongside serial ports, supporting bidirectional transfers for ladder logic, data tables, and fault buffers between PLC and PS/2 hosts with minimal latency. Error detection via parity and handshakes prevents garbled setpoints during high-volume polls, while configurable baud rates adapt to modem links or direct cables. The module buffers bursts, letting PLCs stay responsive during PC-side edits or trending spikes

Rugged design fits standard GE rack slots with keyed insertion, drawing power from the backplane to avoid extra fusing, and EMI shielding suits motor-heavy bays. Low-profile terminals ease field wiring, with status LEDs signaling link-up and activity for at-a-glance checks. GE IC647WMI620 integrates with Workmaster software for screen mirroring and keypad emulation, turning a standard PC into a portable panel.

Long-term, self-resetting fuses and watchdog timers flag link drops early, with MTBF tuned for continuous duty; hot-swappable in some configs minimizes outages. Compatibility spans Series Six to early 90s platforms, easing migrations while supporting printer daisy-chains for hardcopy logs.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | IC647WMI620 |

| Brand | GE Fanuc |

| Type | PS/2 Workmaster interface module |

| Interface Type | Parallel and serial (RS-232) |

| Data Transfer Rate | 500 KB/s parallel |

| Power Supply | Backplane supplied (5V/24V DC typical) |

| Compatibility | GE Series Six, Workmaster II PCs |

| Baud Rates | Configurable up to 19.2 kbps serial |

| Mounting | PLC rack slot, plug-in |

| Operating Temperature | 0 to 60°C industrial |

| Dimensions | Standard GE module (approx. 5″ x 1″ x 6″ D) |

| Weight | Approx. 0.5 lbs |

| Environmental Rating | Indoor industrial, EMI hardened |

| Cooling | Natural convection |

Related Modules or Compatible Units

IC647WMI620/RR – Ruggedized variant of GE IC647WMI620, adds enhanced serial buffering for longer cable runs.

IC647WMI920 – Series 90 parallel interface sibling, shares protocol for mixed PLC fleets with GE IC647WMI620.

IC646TRT300 – CIMPLICITY HMI terminal, pairs for PC-less operator access alongside GE IC647WMI620 links.

Workmaster II cards – PS/2 expansion boards that extend GE IC647WMI620 to multi-drop networks.

IC697 modules – Series 90-70 comms, interoperable for upgrades from GE IC647WMI620 Series Six setups

Installation Notes & Maintenance Best Practices

Slot GE IC647WMI620 into unused rack positions after powering down, confirming pinouts match Series Six maps and twisting serial pairs for noise rejection over 50-foot runs. Bench-test handshakes with a loopback before live tie-in, allocating fuses on host PC ports and grounding shields at one end only. Label cables by function—parallel for dumps, serial for polls—and verify baud parity in Workmaster setup to dodge sync losses.

Visuals quarterly catch loose connectors or LED faults, with cable swaps every two years in high-flex zones; download PLC buffers monthly to baseline transfer integrity. Firmware checks via GE tools spot updates fixing baud quirks, while sparing modules on-site cuts swap time. GE IC647WMI620 stays solid with dry contacts segregated from power wiring.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626