Description

Real-World Use & Application Scenarios

Heavy industry turns to GE IC640WMI610 when medium-voltage motors powering pumps, fans, and compressors face risks from prolonged starts, unbalanced supplies, or jammed loads that threaten winding damage and process halts. Deployed in oil and gas platforms, cement kilns, and metal processing lines, it tackles environments with voltage sags, harmonic distortion, and dusty air where standard breakers fall short on selectivity. Plant managers count on it to catch thermal buildup during acceleration or single-phasing faults, tripping precisely to protect assets without cascading outages across shared feeders.

Tied into industrial automation frameworks, GE IC640WMI610 logs start times, RTD temperatures, and fault waveforms for SCADA review, aiding decisions on load shedding or maintenance scheduling in control systems. Retrofit projects in aging motor control centers benefit from its drop-in compatibility, handling service factors up to 1.15 while coordinating with upstream relays. Engineers specify GE IC640WMI610 for applicable in control systems scenarios involving variable torque drives or high-inertia loads, where underpower detection prevents dry-run cavitation and stall logic blocks restarts on hot rotors. In power plants backing emergency systems or factories running 24/7, it delivers the oversight needed for IEEE-compliant protection amid grid instability.

Product Introduction & Positioning

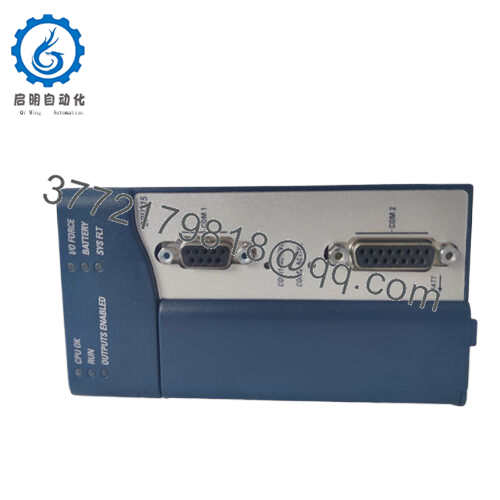

GE IC640WMI610 operates as a numerical motor management relay in GE’s IC640 lineup, focused on overload, unbalance, and mechanical stress protection for induction motors up to several megawatts. It runs thermal models integrating rotor and stator heat, processes CT/RTD inputs, and commands trips via hardwired outputs or serial links to plant automation. Sitting in MCC panels or dedicated enclosures, GE IC640WMI610 bridges field devices to DCS layers, exporting metrics like slip speed and demand kW for centralized monitoring.

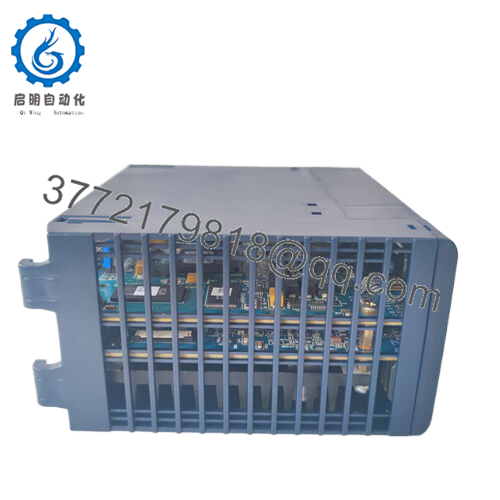

The WMI610 variant tailors features—think wide-range DC power, multiple RTD channels, and flex logic—for sites needing precise stall timing or dependent restarts. What draws integrators is GE IC640WMI610‘s unified platform with GE feeder units, cutting training needs while offering drawout access for live testing. Its bias-adjusted unbalance curves and hot/cold stall ratios adapt to motor data sheets, simplifying setup across diverse drives and boosting uptime through data-driven alerts.

- IC640WMI610

- IC640WMI610

Key Technical Features & Functional Benefits

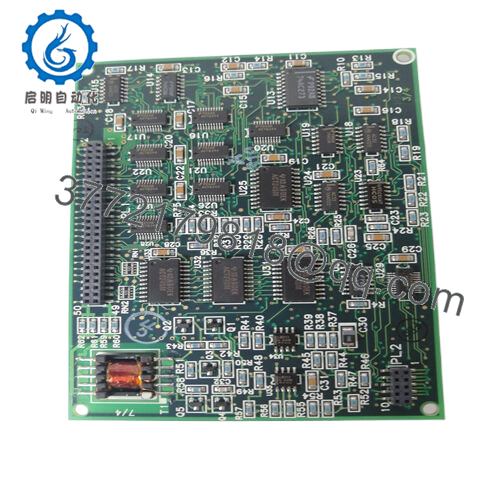

GE IC640WMI610 centers on a thermal image model that tracks capacity used during starts, overloads, and cooldowns, using running/cooling constants from motor sheets to mimic real heat flow and avoid false trips on brief peaks. Unbalance protection (46) applies IP² heating with K-bias for negatives, riding through asymmetries while alarming early derates; stall/inrush (48/14) separates hot/cold curves for safe acceleration under low voltage. Ground elements (50N/51N) sum residuals sensitively, with acceleration timers overriding nuisance picks during tough starts.

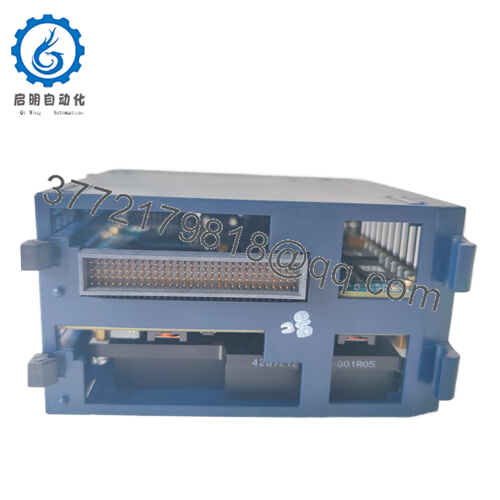

Hardware delivers a front display for on-site tweaks, programmable I/O for interlocks, and 10 RTD inputs spanning stator to bearings, all in a rugged drawout case for EMI-prone floors. RS-485 Modbus pulls trending data like PF and trip counters, expandable for remote inhibit signals without panel mods. GE IC640WMI610 flags shorts above LRC (locked rotor current) yet below fuse curves, using instantaneous settings tuned for DC offset.

Over time, self-checks and event buffers support condition monitoring, with RTD trips at insulation limits (e.g., 150°C for Class F) providing layered defense. Natural cooling and broad temp range suit non-air-conditioned spaces, while logic blocks prevent back-spin or hot restarts, extending motor life in cyclic duty.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | IC640WMI610 |

| Brand | GE Multilin |

| Type | Numerical motor protection and management relay |

| Power Supply | 48-125 V DC or 110-250 V DC |

| Current Inputs | 1A/5A CT, supports 3/6 CT configs |

| Operating Frequency | 50/60 Hz |

| Key Functions | Thermal overload (49), unbalance (46), stall (48), ground fault (50N/51N), short circuit, RTD protection |

| RTD Inputs | Up to 10 for stator/bearings |

| Digital I/O | Programmable inputs/outputs, 48-250 V DC |

| Communications | RS-485 Modbus RTU |

| Mounting | Drawout, 19-inch rack/panel |

| Dimensions | Approx. 10″ H x 8″ W x 7″ D |

| Weight | Approx. 15 lbs |

| Environmental Rating | -40 to +55°C, indoor use |

| Cooling | Natural convection |

Match settings to motor FLA, LRT, and curves per GEK docs.

Related Modules or Compatible Units

IC640WMI6 – Base series model, core thermal logic matchingIC640WMI610 but with variant I/O scaling

339/369 motors – Prior GE relays, direct upgrade path sharing protocols with IC640WMI610.

469 PMU – Enhanced motor manager, Ethernet-ready companion for mixed fleets including IC640WMI610.

DEC1000 expander – Boosts outputs via rear port for IC640WMI610 SCADA links

UR 869 – Next-gen motor relay, interoperable metering/logic with IC640WMI610

IC640 feeders – Coordinates overload curves upstream of IC640WMI610 motors.

Installation Notes & Maintenance Best Practices

Match GE IC640WMI610 CT ratios to FLA, verifying polarity and residual summing for ground pickup, with wiring segregated to cut noise from VFDs nearby. Bench-test logic for stall delays and RTD alarms pre-install, ensuring drawout clearance and DC fusing; torque terminals to spec during panel-in. Ground frame per site codes, labeling flex elements for run/block status.

Annually inspect vents for debris, download logs for thermal trends, and verify K-bias against unbalance history; retest RTDs semi-yearly post-cleaning. Curve tweaks follow motor changes or grid shifts, with software polls spotting breaker wear early. GE IC640WMI610 rewards routine event reviews, heading off overload drifts

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626