Description

GE IC600PM500 CPU/DPU Power Supply – Real-World Use & Application Scenarios

Mid-sized factories and utility plants count on unflinching power stability to run PLC scans through voltage sags from arc furnaces or pump starts that would otherwise freeze material sorters or batch mixers. The GE IC600PM500 anchors Series Six control systems in industrial automation like plastics extrusion, textile winders, and district heating controls, feeding clean dc to CPUs and I/O so sequences complete without glitches during feeder faults or motor reversals. Operators in these setups face daily battles with dirty utility power, and this module steps up by holding rails steady, preventing watchdog trips that cascade into full line stops.ebay+2

Engineers slot the GE IC600PM500 into control systems where rack reliability trumps capacity, such as remote compressor stations or packaging fillers interfacing discrete sensors over noisy floors. It thrives in retrofits swapping narrow-range supplies for wide-input tolerance, supporting applications from palletizers to filler valves where a single rack handles mixed analog/digital loads without auxiliary boosters. In environments shared with welders and inverters, the module’s filtering cuts ripple that could corrupt counter presets or PID tuning

Beyond discrete manufacturing, the GE IC600PM500 powers substation interlocks and HVAC sequencing in high-rises, enduring harmonic loads from elevators while energizing memory backups for outage recovery. Applicable in control systems tied to Genius networks, it ensures DPU handshakes stay live, letting supervisors monitor yields or alarms from central desks rather than chasing panel resets. This frontline role in industrial automation builds trust among crews who swap modules during shifts, valuing quick restarts over deep diagnostics.

Product Introduction & Positioning

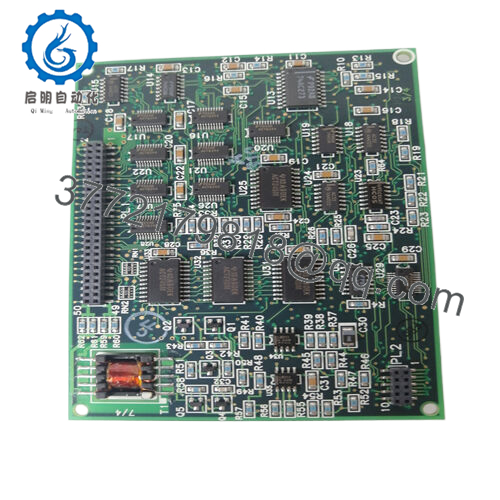

The GE IC600PM500 functions as a CPU/DPU power supply module in GE Fanuc’s IC600 Series Six programmable controllers, stepping down wide ac inputs to precise dc voltages for processor and distributed processing units. It slides into dedicated rack slots, fanning out +5V logic and auxiliary rails across backplanes to sustain ladder execution, data tables, and inter-rack communications in standalone or expanded enclosures

Within control architectures, the GE IC600PM500 forms the electrical spine, isolating CPU power from I/O demands to avoid cross-talk during peak scans or remote drops. This design suits integrators extending legacy systems with Genius bus links, where consistent voltage prevents sync losses between local and remote nodes.

Technicians lean on the GE IC600PM500 for its drop-in simplicity in field upgrades, matching footprints of earlier PM500L variants while broadening input flexibility for global sites. Positioned as the dependable core for mid-tier automation, it balances cost with resilience, enabling Series Six PLCs to coexist with SCADA overlays without power-related faults derailing operations.

Key Technical Features & Functional Benefits

Switching topology in the GE IC600PM500 delivers tight regulation across full loads, recovering swiftly from inrush when CPUs boot or I/O banks energize simultaneously. Low ripple keeps timing pulses crisp, vital for high-speed apps like flying shears or registration marks.

Rugged sheetmetal housing equips the GE IC600PM500 for cabinet depths with finger-safe terminals and led status for at-a-glance health checks. Weighing about 3 kilograms, its rack form locks securely, resisting vibration from punch presses or fan trays.

The GE IC600PM500 mates natively with IC600 CPUs, DPUs, and high-density I/O, extending to remote racks via carrier power without derating. Front-facing diagnostics tie into PLC words for trending dropouts tied to plant events

Built-in overcurrent and thermal cutoffs extend the GE IC600PM500 lifespan in dusty or warm panels, with capacitors rated for decades under continuous duty. Fault relays signal upstream breakers, isolating racks without plant-wide blackouts.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | IC600PM500 |

| Brand | GE Fanuc (General Electric) |

| Type | CPU/DPU AC power supply for Series Six PLC racks |

| Power Supply Input | 95-260 VAC, 47-63 Hz wide range |

| Output Voltages | +5 VDC primary, auxiliary rails for logic and memory |

| Operating Temperature | 0 to 55 degrees Celsius, enclosed panel use |

| Mounting | IC600 rack slot, vertical installation |

| Dimensions | Standard Series Six module: approx. 260 x 40 x 200 mm |

| Weight | 3.18 kilograms |

| Interfaces | Backplane power bus, front AC terminals and status LEDs |

| Certifications | UL/CSA listed for industrial automation power supplies |

| Cooling | Natural convection with rack ventilation |

| Environmental Rating | Indoor IP20, control cabinet suitable |

- IC600PM500

- IC600PM500

Related Modules or Compatible Units

IC600CP624 – Complementary rack power supply for expanded I/O alongside IC600PM500 CPU feeds in multi-slot systems.

IC600LX605 – Series Six CPU module powered directly by IC600PM500 for core ladder processing.

IC600KD514 – Operator interface drawing stable rails from IC600PM500 for reliable switch and lamp operation.

IC600CB537 – Exciter module sharing Series Six power architecture with IC600PM500 in control panels

IC600PM503 – High-capacity I/O power variant pairing with IC600PM500 for dense rack configurations.

IC600LX624 – Memory module sustained by IC600PM500 outputs in program-intensive applications

Installation Notes & Maintenance Best Practices

Seat the GE IC600PM500 in the prescribed slot per rack loading charts, twisting ac leads with ferrules to spec torque and routing away from signal cables to dodge induced noise. Verify phase balance on three-phase feeds and strap jumpers for 115/230 selection if equipped, cycling power post-wiring to baseline LED patterns before CPU insertion. Secure drip shields over vents in humid zones, grounding chassis via rack frame.

Quarterly peeks inside the GE IC600PM500 catch fan dust or terminal heat, with multimeter sweeps of outputs under no-load to flag drift. Relay tests during shutdowns confirm fault latching, while capacitor ESR checks every outage predict end-life before summer peaks hit. Stock fuses matching slo-blo ratings onsite, and log serials against GEI manuals for traceability in compliance audits.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626