Description

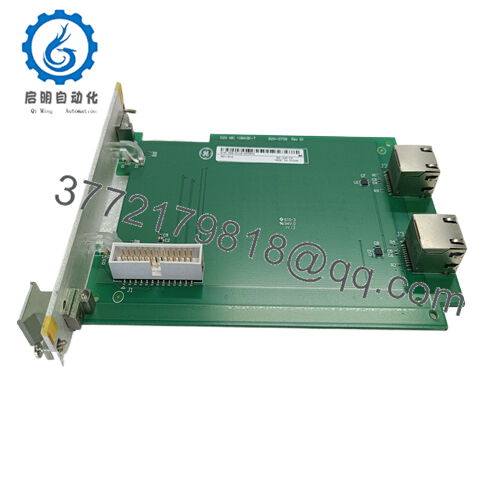

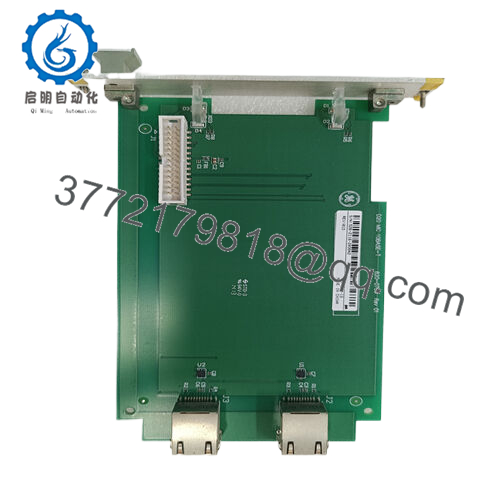

Product Model: GE IC3600SSKA1

Product Brand: General Electric

Product Series: Speedtronic Mark II

Product Features:

- Designed for stable relay output control in turbine systems

- High tolerance against thermal fluctuation and vibration

- Compatible with GE Mark II/legacy control panels

- Reliable long-term performance and simple diagnostic handling

Technical Specifications

| Specification | Description |

|---|---|

| Model | GE IC3600SSKA1 |

| Brand | General Electric |

| Series | Speedtronic Mark II |

| Function | Output control relay interface |

| Recommended Application | Gas/steam turbine logic sequencing |

| Supply Power | Bus-fed from control rack |

| Operating Range | -10°C to +65°C |

| Vibration Tolerance | Designed for turbine enclosure proximity |

| Control Type | Discrete signal actuation |

| Rack Type | IC3600 standard backplane |

| Diagnostics | Test points accessible via multi-meter |

| Inspection Interval | Every 12–18 months (recommended) |

| Replacement Style | Plug-in, non-coded |

- IC3600SSKA1

- IC3600SSKA1

Technical Features & Benefits

The GE IC3600SSKA1 is engineered to withstand harsh conditions found within turbine control enclosures. Unlike contemporary boards that rely heavily on PCB miniaturization, this module utilizes a robust physical layout optimized for heat dissipation and electrical stability. Impedance balancing across relay circuits helps prevent transient signal interference, especially during high-voltage switching events.

Engineers value its long-term functional reliability. While some equipment may fault after extended thermal cycling, the GE IC3600SSKA1 demonstrates consistent operational behavior provided basic care is maintained. One engineer from a UK combined cycle plant reported a near-zero failure rate over 15 years for these output cards, attributing it to minimal electronic complexity and superior hardware tolerance.

Among key benefits:

- Vibration resistance: Reinforced trace layout reduces support failures caused by constant turbine casing vibration.

- Thermal stability: Handles ambient fluctuations effortlessly, commonly ranging from chilled start-ups to hot enclosure build-up.

- Low maintenance complexity: No software calibration required—standard electrical tools suffice for diagnosis.

- Safety integration: Geared toward turbine trip logic, providing fast relay closure during emergency conditions.

When replacing units, there’s no need for programming software. Simply insert the GE IC3600SSKA1, verify terminal connectivity, and test via system diagnostic checks.

Even during modernization projects, technicians retain this module to act as a final protective device, relying on its proven performance to handle high-stress turbine shutdown procedures.

Related Models

- GE IC3600SSKA1A – Enhanced output revision with updated contact profile

- GE IC3600LRDH1 – Logic relay driver board

- GE IC3600SRMD1 – System sequencing control module

- GE IC3600STKJ1 – Temperature monitoring interface

- GE IC3600AFGA1 – Fuel gas system control card

- GE DS200SSBAG1 – Modernized Mark V replacement option

- GE DS215SDCCG1AZZ01 – Next-generation Mark VIe module

- GE IC3600AOAH1 – Analog output interface card

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626