Description

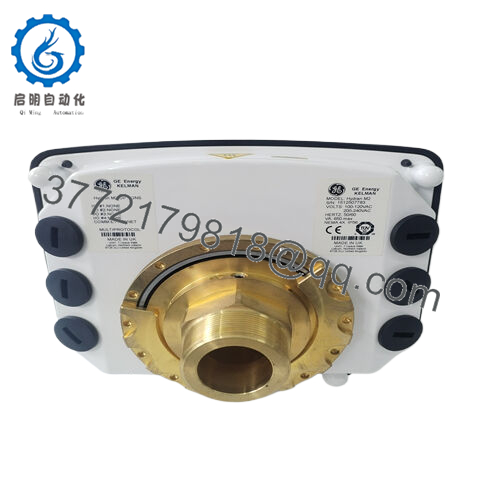

GE Hydran M2 Product Description:

GE Hydran M2 is an online transformer detection gas equipment designed specifically for the electrical equipment industry. It adopts a continuous cycle working mode to ensure the stable operation of transformers.

Hydran M2

Main features and advantages:

Gas and humidity monitoring

It can continuously monitor the comprehensive value of multiple fault gases (in ppm), or only monitor the hydrogen value (depending on the type of sensor purchased). For example, the ability to accurately detect the generation and accumulation of gases such as hydrogen, acetylene, methane, ethane, and ethylene, whose abnormalities are often important signs of insulation material failure. At the same time, it can also track the moisture content in oil in real time (measured in% RH and ppm). For oil immersed transformers, humidity monitoring is crucial for evaluating insulation performance and preventing problems caused by humidity.

When using a composite gas sensor, its response rate to hydrogen gas reaches 100%, and it is also sensitive to carbon dioxide (produced by overheated paper insulation); If a hydrogen sensor is selected, it will show a 100% response to hydrogen gas.

Multivariate data processing and model computation: After adding additional sensors, Hydran M2 can be processed according to IEEE standards ® And IEC ® Constructing a standard mathematical model for transformers provides richer information for a deeper understanding of transformer performance. For example, by connecting sensors such as top and bottom oil tank oil temperature, transformer load, or ambient temperature, more information can be collected and correlated with fault gas and humidity values for in-depth analysis. At the same time, it can transmit raw data through various communication methods and convert the data into a transformer mathematical model based on IEEE standards through onboard computing, outputting useful information such as estimated winding hotspot temperature, moisture content in paper, moisture foaming temperature, insulation aging degree, overload capacity, cooling efficiency, on load tap changer (OLTC), etc., to help operation and maintenance personnel comprehensively grasp the health status of transformers.

Convenient installation and reliable operation: The device has a compact structure and can be permanently installed on a single transformer oil valve without the need for additional pipelines or pumps, making installation simple. There are no moving parts inside, reducing the possibility of malfunctions. Equipped with a vacuum resistant gas extraction membrane and a built-in temperature regulation system, it can adapt to complex working environments and ensure stable operation of the equipment. Automatic comprehensive self inspection is conducted every 15 days. If a fault is detected (including power failure, oil valve closure, sensor failure, etc.), a service alarm will be immediately triggered. At the same time, it has a complete self diagnostic function, which can detect sensor faults or system problems in a timely manner and issue corresponding alarms.

Wide communication and flexible configuration: Supports multiple communication methods and protocols, making it easy to integrate into SCADA or DCS systems. The standard configuration is RS485 output, and TCP/IP copper cable or fiber optic output can also be optionally selected. Up to 4 input or output cards can be selected for easy connection to other devices or function expansion. It can flexibly set local and remote alarms according to needs, with two alarm levels (one for early warning and one for alarm). When a fault gas or abnormal humidity level is detected, an alarm will be issued in a timely manner to remind operators to take corresponding measures and reduce the risk of equipment damage or accidents. In addition, alarms can be set based on optional analog input cards or calculated transformer models.

Data recording and storage: With data recording and storage functions, it can record data and important events for up to one year, facilitating subsequent analysis of equipment health status and performance history, and providing strong data support for equipment maintenance and management.

Hydran M2

Application areas:

Transformer monitoring: It can monitor the operating status of transformers in real time, detect potential problems in a timely manner, such as abnormal temperature rise, humidity changes, sediment accumulation, and gas anomalies, and help operation and maintenance personnel take measures in advance to avoid the expansion of faults.

Fault diagnosis: By continuously monitoring key parameters of the transformer, Hydran M2 can assist in fault diagnosis. Once a problem that may cause equipment failure is detected, an alarm will be immediately issued, providing a basis for rapid location and resolution of the fault.

Gas analysis in oil: With precise monitoring of gas content in oil, this equipment can reveal the internal state of transformers, such as gases generated by partial discharge, arc, and other faults, thereby gaining a deeper understanding of the operating conditions inside transformers.

Temperature monitoring: It can not only monitor the internal temperature of the transformer, but also the external environmental temperature, help evaluate the thermal stability of the equipment, identify abnormal temperature rise in advance, and ensure that the transformer operates within the appropriate temperature range.

Remote monitoring: With the help of network connectivity, Hydran M2 enables remote monitoring, allowing operation and maintenance personnel to access key status information of transformers at any time, regardless of their location, greatly improving operation and maintenance efficiency and timeliness.

Hydran M2

Hydran M2

Other GE brand product models:

GE 469-P5-HI-A20-E-H

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

GE 5266222-2 – GSCB GOC6.6

GE IS400AEBMH1AJD

GE DS200TCQCG1AJD

GE 239-RTD-AN

GE 239-RTD-AN

GE 239-RTD-AN

GE 269PLUS-100P-120VAC

GE IS420UCSBH1A

GE Physical 239 239-RTD-AN

GE VMIVME2540-300

GE 8507-BI-DP 8507-BI-DP-01

GE VMIVME2540

GE SLN042 IC086SLN042-A

GE SLN080 IC086SLN080-A

GE VMIACC-5595-208 350-805595-208N

GE SBC486DX66

GE F650 F650BFBF2G0HIE

GE VMIACC-5595-208

GE IS215WEPAH2B

GE IS210AEAAH2B

GE 239

GE 369 panel

GE IS210AEBIH3B

GE IC660EPM100J

GE VPROH2B IS215VPROH2BC

GE DS2020PDMAG6

GE IS220UCSAH1A

GE DS200TCQCG1AJD

GE IS200ECTBG1ADE

GE IS200EXHSG3REC

GE IS220PPDAH1A

GE 845-EP5M5G5HNNAANGAPBCSENWB

GE 336A5199AMP1

GE F35-C-U03-HUH-F8L-H67-M6T-PXX-UXX-WXX

GE C60-C-U03-HUH-F8L-H6U-M6D-P6D-U6T-WXX

GE HE700GEN200

GE IC697BEM763

GE 339-E-P1-G1-H-E-S-N-P-1E-D-N

GE DS3800NB1B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626