Description

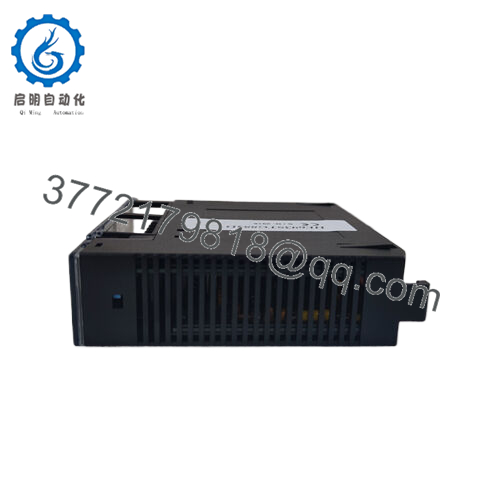

The GE HE693STG884D is a high-resolution strain gauge input module designed for connection to Programmable Logic Controllers (PLCs) in industrial automation systems. This module is specifically engineered to interface directly with bridged strain gauges, such as load cells, without requiring external signal processing hardware. Its advanced design enables precise measurement of strain signals critical for applications involving force, weight, pressure, and other mechanical stresses.

Key technical details of the HE693STG884D include support for input voltage ranges of ±25 mV, ±50 mV, and ±100 mV, accommodating a wide variety of strain gauge types and sensitivities. The module provides selectable resolutions of 0.8 µV, 1.6 µV, and 3.2 µV respectively, ensuring highly accurate signal conversion and data fidelity. It features eight input channels, allowing simultaneous measurement from multiple sensors. The module interfaces directly with the PLC backplane, facilitating easy installation and integration into existing control systems.

The HE693STG884D is designed to support industrial operational requirements, providing reliable performance in harsh environments. It is typically used in sectors such as manufacturing, aerospace, automotive testing, and any application demanding precise strain or load measurements for quality control or system monitoring.

| Parameter | Value |

|---|---|

| Model | GE HE693STG884D |

| Manufacturer | General Electric (Fanuc/Horner) |

| Product Type | High-Resolution Strain Gauge Input Module |

| Number of Channels | 8 |

| Input Voltage Range | ±25 mV, ±50 mV, ±100 mV |

| Resolution | 0.8 µV, 1.6 µV, 3.2 µV |

| Signal Type | Bridged strain gauge (load cells) |

| Interface | Direct backplane connection |

| Application | Force and strain measurement |

- HE693STG884D

The HE693STG884D excels in providing direct, noise-free analog signal input from strain gauges, making it ideal for applications requiring high precision and reliability without additional external amplifiers or converters.

Installation typically involves mounting the module within the PLC rack with secure backplane connectivity. Proper shielding and grounding of strain gauge cables are necessary to maintain signal integrity. Calibration and configuration are performed via the PLC programming environment, ensuring integration with broader control workflows.

Maintenance focuses on signal verification and periodic recalibration to maintain measurement accuracy, along with inspection of wiring and connectors to prevent signal degradation.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626