Description

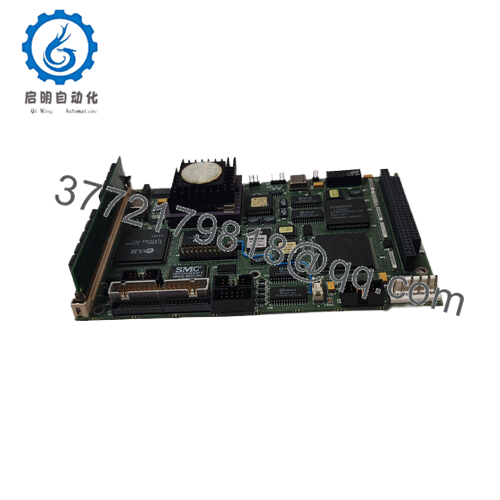

The GE DS200UCPBG6AFB is a multifunctional I/O card and an important component of GE’s advanced control system. It is a critical connection between on-site devices such as sensors and actuators and advanced control units.

DS200UCPBG6AFB

In a typical control system architecture, it receives analog and digital signals from various sensors distributed throughout the factory workshop. These signals may include temperature readings from thermocouples, pressure measurements from pressure sensors, and status signals from switches. Then, the GE DS200UCPBG6AFBprocesses this data, converts it into a format that the central control system can understand, and sends control signals to actuators such as valves and motor drivers to adjust the process accordingly.

DS200UCPBG6AFB

Main features and advantages:

From a functional perspective, the GE DS200UCPBG6AFB is excellent. It can process various input signals with extremely high precision. For analog inputs, it provides high-resolution conversion to ensure accurate detection of small changes in process variables. This precision is crucial for maintaining tight control over the process. In terms of output capability, it can drive actuators with sufficient power and speed to achieve fast response time. For example, when there is a sudden change in process conditions that requires immediate adjustment of valve position, GE DS200UCPBG6AFB can send appropriate control signals within milliseconds.

The hardware design of GE DS200UCPBG6AFBis both robust and compact. It can withstand the harsh environmental conditions commonly found in industrial environments, such as high temperature, humidity, and electromagnetic interference. The module is enclosed in a sturdy casing to protect its internal components. Its compact size makes it suitable for installation in control cabinets where space may be limited. It usually adopts standard installation mechanisms, such as DIN rail installation, which simplifies the installation process.

Compatibility is a major advantage of GEDS200UCPBG6AFB. It supports multiple industry standard communication protocols, including Modbus and PROFIBUS. This allows it to seamlessly integrate with devices in other control systems, such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other I/O modules. Whether connected to GE branded PLCs or third-party devices, the GE DS200UCPBG6AFB can establish a reliable communication link.

In terms of long-term reliability, the GE DS200UCPBG6AFB adopts redundant components and self diagnostic function design. Redundant power supplies and communication channels ensure that the module can continue to operate without interruption in the event of component failure. The self diagnostic function continuously monitors the health status of the module and detects any potential issues such as overheating, memory errors, or communication failures. If a problem is detected, the module can generate an alert and take corrective measures to minimize downtime.

DS200UCPBG6AFB

Technical specifications:

Model DS200UCPBG6AFB

Brand GE

Type: Multi functional I/O card

Input voltage 24 V DC (± 10%)

Communication protocols Modbus, PROFIBUS

Installation type DIN rail installation

Working temperature -20 ° C to 60 ° C

Humidity range 5% -95% (non condensing)

Redundant functions, redundant power supply, communication channels

Self diagnostic function monitors overheating, memory errors, and communication failures

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

DS200UCPBG6AFB

Application areas:

In thermal power plants, the steam turbine rotates at high speed to generate electricity. The GE DS200UCPBG6AFB is integrated into the control infrastructure to precisely regulate fuel injection and steam flow to the turbine. This not only optimizes power output, but also protects mechanical equipment from the effects of overload or low efficiency. For example, during peak electricity demand periods, this module can quickly adjust input parameters to meet load requirements while maintaining stable operation. In hydropower plants, it controls the flow of water to the turbines, adapts to changes in water level, and ensures stable power production.

In industrial manufacturing facilities that use large motors and machinery, the GEDS200UCPBG6AFB is used to manage the start, stop, and speed control of these critical assets. It can interface with sensors that monitor temperature, vibration, and load, and adjust in real-time based on the received data to prevent equipment failure. This is crucial in industries such as steel production, as continuous operation is essential for productivity and profitability.

DS200UCPBG6AFB

Related products:

GE DS200UCIPA1AAC – It may be used to expand the input capability of the system, such as for additional sensor connections. This may be beneficial in control systems that require interfaces with a large number of different types of sensors.

GE DS200DPCBG1AAA – This module may be related to control functionality. It may be used to handle specific control algorithms or interface with other parts of the control infrastructure, supplementing the I/O functionality of GE DS200UCPBG6AFB.

GE DS200SDCIG2AFB – As a framework transient data interface module, it can manage and transmit transient data together with GE DS200UCPBG6AFB, which is important in applications that require rapid processing and response to sudden changes in process data.

GE DS200TCQAG1BFD – As an analog I/O board, it can be paired with GE DS200UCPBG6AFB to enhance the system’s analog I/O capabilities, allowing for more precise control of analog based processes. GE DS200TCRAG1A – As a relay output board, it can be used in conjunction with GE DS200UCPBG6AFB to control high-power equipment.

The GE DS200UCPBG6AFB can send control signals to the board, which then switches relays to open or close equipment such as motors or large valves.

Installation and maintenance:

Before installing GE DS200UCPBG6AFB, several precautions must be considered before installation. Firstly, the size of the control cabinet for installing it should be determined correctly. Ensure there is sufficient space around the module for proper ventilation. Proper ventilation is crucial as modules may generate heat during operation, and overheating can lead to performance degradation or even component failure. The control cabinet should also be located in an area away from excessive dust, moisture, and strong electromagnetic fields. Grounding is another key aspect. Appropriate grounding connections must be established to protect the module from the impact of power surges and ensure accurate signal transmission. The grounding resistance should be within the range specified in the installation guidelines.

In terms of maintenance, it is recommended to conduct regular visual inspections. These checks should be conducted at least once a month. Check for any physical signs of damage to the module, such as cracked casing, loose connectors, or signs of overheating. Any visible issues should be addressed immediately. Signal diagnosis should be conducted quarterly. This involves checking the accuracy of input and output signals. Compare the signal received by the sensor with the signal processed by the module, and ensure that the control signal sent to the actuator is appropriate. In addition, it is important to keep the firmware of the module updated. GE will regularly release firmware updates, which may include bug fixes, performance enhancements, and new features. Updating firmware in a timely manner helps to maintain optimal operation of the GE DS200UCPBG6AFB.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626