Description

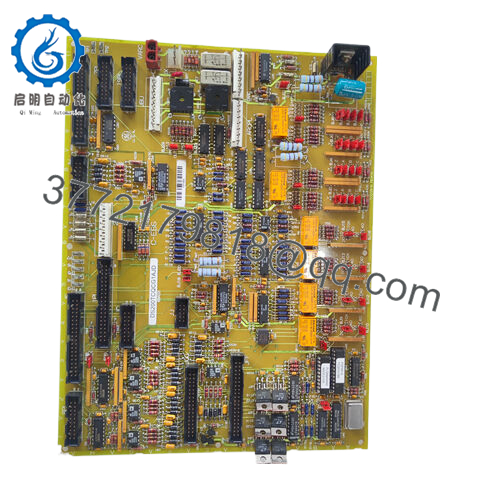

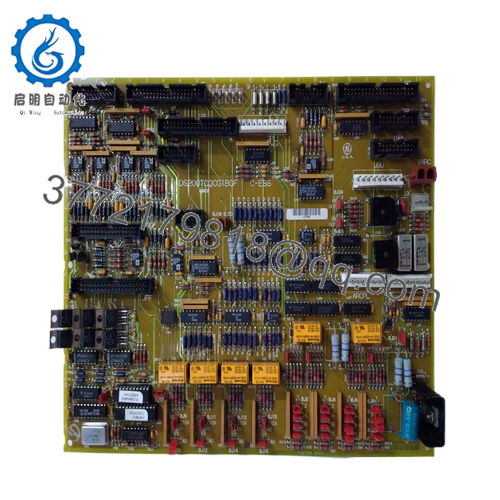

In the high-stakes realm of turbine control systems, where overflow processing delays or signal overflows can precipitate unsafe transients or control loop instabilities—envision a gas turbine startup sequence in a combined-cycle plant where unhandled data surges from R, S, and T controllers overwhelm sequencing logic, risking overspeed trips and fuel inefficiencies, or a steam turbine in a utility station where voltage feedback overflows amid load rejections expose governors to erratic commands and grid penalties—these vulnerabilities demand robust buffering to maintain process integrity and prevent cascading faults. Such issues are prevalent in legacy Mark V architectures, where standard core processors falter under peak data loads from protective functions or sequencing, leading to I/O bottlenecks, diagnostic ambiguities, or scalability constraints that extend outages and inflate retrofit expenses in high-reliability process control environments. The GE DS200TCQCG1BGF addresses this as an RST overflow board from GE’s Speedtronic Mark V series, engineered to extend processing capacity for the three core controllers (R, S, T) by handling excess data and generating auxiliary outputs, ensuring high-fidelity signal management and seamless turbine coordination under dynamic operational stresses.

This board becomes indispensable in mid-to-large turbine installations, such as retrofitting Mark V systems for enhanced sequencing in aero-derivative units, where modular buffering prevents data loss without full core overhauls, or in industrial cogeneration where variable loads from renewables require adaptive overflow handling to avert nuisance alarms. In a peaking gas turbine, for instance, it absorbs surge data from vibration monitors during rapid ramps, delivering precise auxiliary signals to damp transients and sustain uptime. For offshore FPSO platforms with vibration-heavy enclosures, the GE DS200TCQCG1BGF incorporates robust isolation to combat EMI, upholding system stability without compromising on jumpers for custom configurations. It’s a key enabler for expansions in multi-shaft Mark V setups, where its compatibility with core I/O bridges legacy protections to modern HMI, aligning with goals of fault isolation in dusty or thermal-variable bays.

DS200TCQCG1BGF

DS200TCQCG1BGF

What resonates in industrial automation is its focus on practical extensibility: populated with 24 jumpers for tailored data routing, it supports overflow from critical algorithms without hardware swaps. In data-dense plants or remote grids, its 40-pin and 34-pin connectors streamline ribbon cabling for clean signal paths, while self-monitoring via status relays preempts buffer overflows. For teams sustaining Mark V fleets, the GE DS200TCQCG1BGF facilitates endurance, reusing DS200 footprints to minimize downtime, shifting from reactive buffering to proactive optimization in process control where overflow resilience anchors every startup sequence.

Tying the GE DS200TCQCG1BGF into your turbine stack positions it as the auxiliary processor extender within GE’s Mark V framework, where it interfaces with R, S, and T controllers via ribbon cables to capture and process overflow data—such as protective trips or sequencing outputs—while generating auxiliary commands for actuators and alarms in control cabinets. This board plugs into Mark V backplanes via edge connectors, nesting at the core extension layer—directly buffering controller streams but relaying refined signals downward to I/O modules like DS200RTBDG for termination. In a layered architecture, it syncs with upstream <R> core for algorithm offload or downstream servo boards for valve drives, distributing overflow loads across the RST triad to evade single-core saturation.

In operation, it manages data at 10 ms cycles, routing excess packets through 3 40-pin (JFF, JE, JPL) and 3 34-pin connectors for error-free handoff, while a 16-pin (JC) link handles status feedback to the core for loop closure. Diagnostics embed via onboard relays and serial ties, surfacing buffer utilization or jumper faults in Toolbox software for remote review—essential in process control where HMI forensics outpace cabinet dives. Without native redundancy, it deploys in duplex Mark V configs for mirrored buffering, where sync pulses ensure seamless failover under 100 ms, and its firmware enables online jumper reprograms without halts.

This adaptability reaches varied Mark V nets: mount it in IP20 enclosures with shielded ribbons, set jumpers via diagrams for custom overflows, and bench-test routing to affirm against packet loss. For backplane experts, the GE DS200TCQCG1BGF clarifies extension, morphing core triads into buffered ensembles that scale with sequencing demands, fortifying industrial automation from overflow chokepoints to resilient regulators.

| Specification | Details |

|---|---|

| Model Number | DS200TCQCG1BGF |

| Brand | GE (Speedtronic Mark V) |

| Type | RST Overflow Board |

| Input Voltage | 5 VDC / 24 VDC |

| Operating Temp Range | -30°C to 65°C |

| Mounting Style | Backplane / Rack |

| Dimensions | 10.16 x 16.51 x 2.54 cm |

| Weight | 0.8 kg |

| Interface/Bus | Ribbon Cable Connectors (40-pin, 34-pin, 16-pin) |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Mark V Internal Bus |

| Typical Power Draw | 10 W |

Harnessing the GE DS200TCQCG1BGF equips your Mark V cores with persistent overflow resilience that masters data deluges, its jumper-configurable buffers—handling up to 10 ms surges—preventing algorithm stalls to uphold 99.9% sequencing fidelity in ramps where overflows desync protections and spawn trips. This dependability extends turbine life by offloading transients from R/S/T, easing thermal strain on processors and optimizing fuel curves in variable-load ops, all within a compact profile that reuses legacy slots without airflow tweaks.

The assimilation advantage deepens with Mark V affinity, where it repurposes ribbon harnesses for add-ons like auxiliary alarms, compressing tie-ins from shifts to setups and lightening opex in turbine arrays. Upkeep refines via relay-embedded logs that chronicle overflows for early alerts, shortening diagnostics from core dives to console scans—empowering teams to reprovision jumpers proactively over post-fault patches. Forged for endurance in steamy or particulate cabinets, it sustains routing integrity over cycles, deferring interventions and syncing with MTBF targets in regulated realms.

The long arc spotlights efficiency amplifiers—modest 10 W draw trims PSU loads, while connector density defers expansions for leaner racks that adapt to sequencing growth. In high-reliability pursuits, the GE DS200TCQCG1BGF tempers total risks, from buffer isolation that quarantines surges to status chains that baseline loads for spares, forging an overflow lattice that navigates flux in turbine control.

In gas turbine peaking units, the GE DS200TCQCG1BGF buffers R/S/T data during fast starts, routing auxiliary signals amid flame roar to secure critical system uptime in process control environments where overflow handling averts governor hunts. Its high-reliability connectors process I/O signals from sequencers, ensuring ramp precision.

Steam turbine islands deploy it for protective overflows under load swings in boiler bays—yielding jumper-tuned paths for continuous baseload where desyncs imperil blade paths. In aero-derivative drives for pipeline compression, it manages surge data against torque flux in remote vaults, supporting modular alarm expansions. These roles exalt the GE DS200TCQCG1BGF as an overflow oracle in grueling, sequence-strict industrial automation, where board buffering meets endurance.

DS200TCQCG1AJD – Predecessor variant for earlier Mark V with reduced jumper count for basic sequencing.

DS200TCQAG1BHF – Enhanced model with additional 34-pin for denser auxiliary outputs in multi-shaft setups.

DS200RTBDG1ALE – Termination board companion for I/O signal conditioning.

DS200TCEAG1BTF – Core interface add-on for R/S/T processor extensions.

DS200SIOCG1A – Serial I/O module for HMI diagnostics in Mark V.

Mark V Overflow Kit – Jumper and ribbon toolset for custom configurations.

DS200TCQCG1AHD – Legacy overflow for non-redundant single-core apps.

IS200TREGH1BEC – Relay extension for TMR-integrated overflows.

Before backplane-seating the GE DS200TCQCG1BGF, verify ribbon pinouts against your Mark V chassis—mismatches ghost signals, so continuity-probe with a meter if splicing revisions. Scrutinize 5/24 VDC rails for <3% ripple, as noise bleeds into buffers; decouple with ferrites if core PSUs hum. Stage firmware via GE’s loader to align with R/S/T OS, circumventing init stalls.

In the long haul, stewardship distills to measured pulses that fit shop rhythms. Monthly, glance at status relays for overflow flags—steady operation sans latches clears the deck, but triggers cue a log dump for pattern spotting. Semiannually, reseat connectors for corrosion and cycle jumper tests per guide specs to benchmark routing under load. For vibration-heavy installs, quarterly torque audits on edge clips to spec counter creep, while annual end-to-end sims validate buffer depths against drifts. Drawing from GE’s Mark V manual, this cadence keeps the GE DS200TCQCG1BGF as a quiet enforcer, exacting minimal toll for maximal sequencing poise.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626