Description

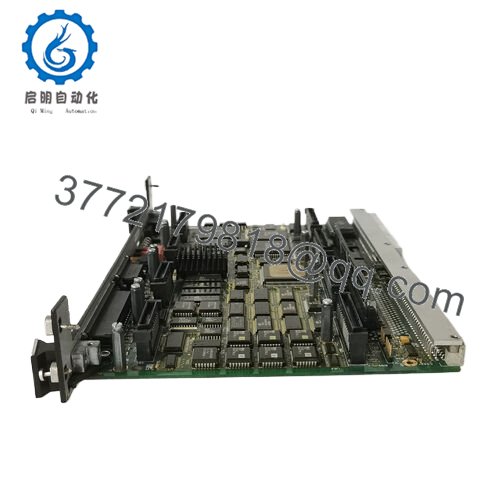

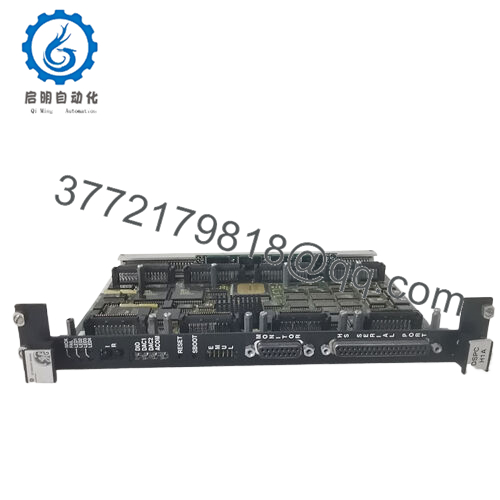

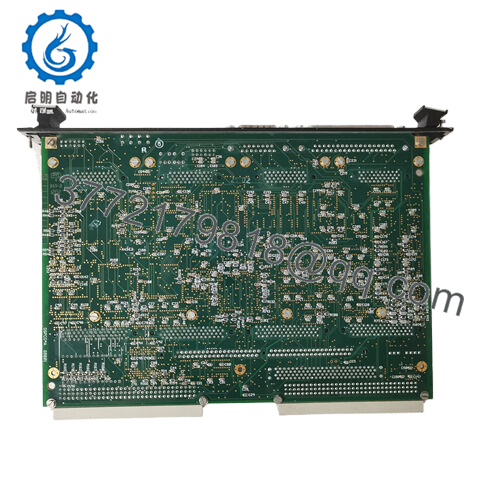

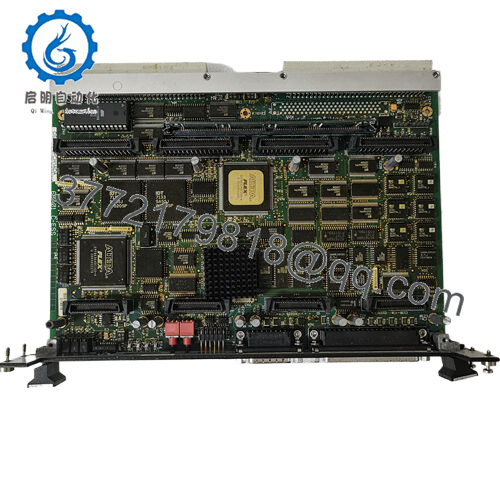

The GE DS200DSPCH1ADA is an advanced digital signal processing and control module that serves as the central nervous system in industrial automation systems. It interfaces with various field devices, including sensors that collect process data and actuators that execute control commands, as well as advanced control platforms such as programmable logic controllers (PLCs) and distributed control systems (DCS).

DS200DSPCH1ADA

This module is designed to receive raw data from various sensors, execute complex digital signal processing algorithms to filter, analyze, and interpret the data, and then generate appropriate control signals for the actuator. It can process multiple data streams simultaneously, ensuring that all relevant information can be processed in real-time. The GE DS200DSPCH1ADAcommunicates seamlessly and exchanges data with other components in the system through industry standard interfaces and protocols such as Ethernet, Modbus, and Profibus.

DS200DSPCH1ADA

Technical specifications:

Model DS200DSPCH1ADA

Brand GE

Type: Digital Signal Processing and Control Module

Input voltage 24 VDC

Working temperature range -40 ° C -70 ° C

Installation method: DIN rail

Dimensions 120mm × 70mm × 50mm

Weight 0.45 kg

Interface/Bus Ethernet RS – 485、RS – 232

Compliance with CE and RoHS

Supported protocols include Modbus TCP, Modbus RTU, Profibus DP, Ethernet/IP

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

DS200DSPCH1ADA

Main features and advantages:

This module is designed for high performance and reliability, capable of withstanding the rigorous tests of continuous industrial operation, reducing the frequency of failures, and minimizing unplanned downtime. This directly translates into increased productivity and reduced long-term maintenance costs.

The advanced data processing capability of this module enables faster and more accurate decision-making. By quickly analyzing sensor data and generating appropriate control signals, it can optimize production processes, improve product quality, and reduce waste. Its seamless integration with existing automation systems simplifies overall setup, reduces engineering costs, and reduces the time required for system debugging. The built-in diagnostic function improves maintenance efficiency, enabling engineers to proactively detect and resolve potential issues, prevent upgrades, and further improve system uptime and reliability. The GE DS200DSPCH1ADA is capable of handling multiple control tasks simultaneously and supports more complex automation scenarios, enhancing the flexibility and adaptability of industrial processes.

DS200DSPCH1ADA

Application areas:

In the automotive manufacturing industry, it is used to control and optimize the operation of robot assembly lines. This module processes data from sensors that monitor the position, velocity, and force of robot arms, enabling precise control of tasks such as welding, painting, and component installation. This helps to improve production speed and quality while reducing errors.

In the chemical processing industry, precise control of chemical reactions is crucial for safety and product quality, and GE DS200DSPCH1ADA plays a key role. It continuously monitors process variables such as temperature, pressure, and flow from sensors, and adjusts control valves and other actuators in real-time to maintain optimal reaction conditions. In addition, in the field of renewable energy, this module can be used to manage the operation of wind turbines or solar power plants. It processes data from sensors measuring wind speed, solar irradiance, and power output, and adjusts the operation of turbines or panels to maximize energy generation while ensuring safe and reliable operation.

DS200DSPCH1ADA

Related products:

GE DS200DSPCH2ADA: Upgraded version with stronger processing capabilities and more control outputs, suitable for more complex and data intensive automation applications.

GE DS180DSPCH1ADA: An affordable alternative product with basic data processing and control functions, suitable for smaller or less demanding industrial settings.

GE DS200DSPCH1BDA: Designed for applications that require fast data exchange between components, it features improved communication interfaces and higher data transfer speeds.

GE DS200DSPCH1ARA: A variant with additional built-in safety features such as redundant control paths and emergency stop function, suitable for safety critical applications.

GE DS200DSPCH1ACA: Designed specifically for high-precision control applications, providing higher precision in control signal generation and data processing, suitable for tasks that require minor adjustments.

GE DS200DSPCH1ABA: Equipped with integrated cloud connectivity, it can achieve remote monitoring, control, and data analysis, supporting more intelligent automation management.

DS200DSPCH1ADA

Installation and maintenance:

Before installing GE DS200DSPCH1ADA, it is necessary to carefully evaluate the data processing and control requirements of the automation system. Ensure that the input voltage supplied to the module is within the specified range to prevent damage. Check the compatibility of communication interfaces and protocols with existing field devices and control platforms. Ensure there is sufficient space for proper installation, as the size and heat dissipation requirements of the module should be met. When configuring the module, set data processing parameters such as sampling rate, filtering algorithm, and control loop settings according to specific application requirements. Meanwhile, allocate unique addresses for seamless communication within the network.

For continuous maintenance, the diagnostic indicator lights and performance indicators of the module should be monitored regularly. These pieces of information can provide valuable insights into the operational status of the module, including data processing efficiency, communication integrity, and control signal accuracy. Regularly check the connections between GE DS200DSPCH1ADA and other devices such as sensors and actuators to ensure they are secure and undamaged. Conduct regular performance testing to verify whether the module accurately processes data and generates appropriate control signals. If any problems arise, please refer to the detailed troubleshooting guide provided by GE to promptly identify and resolve the issue.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626