Description

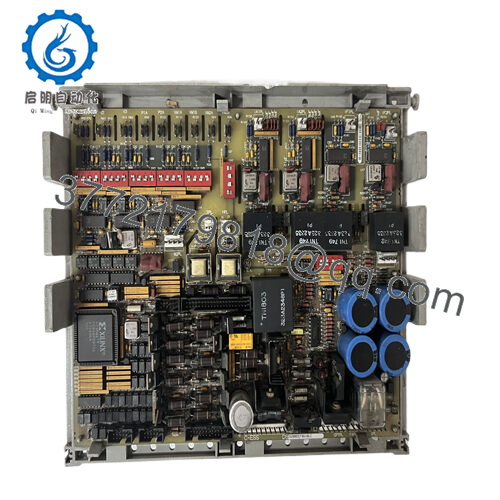

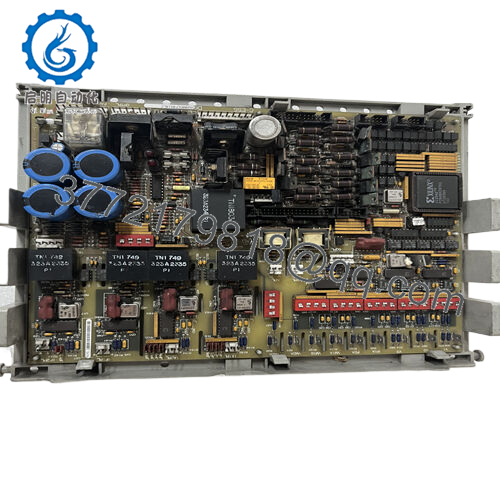

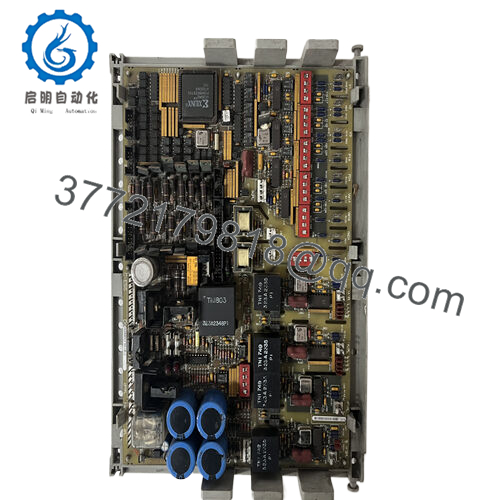

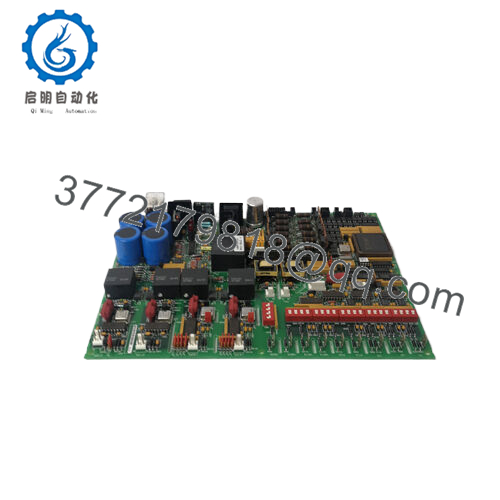

The GE DS200DCFBG1LC is a DC power supply feedback board designed for use in GE’s automation and drive systems, including the EX2000, DC2000, CB2000, FC2000, GF2000, ME2000, and AC2000 series. This board plays a crucial role in power supply monitoring and control by converting input AC and DC power signals into precise feedback signals required for the drive’s operation and the enclosure’s cooling fans. It is specifically engineered to handle the monitoring of AC line and DC motor signals, ensuring the drive system receives stable and controlled power. This makes the DS200DCFBG1LC indispensable in industrial automation environments where power quality and system feedback are critical for maintaining drive efficiency and preventing system faults.

The DS200DCFBG1LC functions as an essential interface board within the power supply architecture of GE’s drive systems. It converts input voltages through voltage-controlled oscillator (VCO) circuits into frequency signals, which are then provided as feedback to other control modules such as the SDCC/LDCC board for operational monitoring and adjustments. This operational feedback ensures accurate control of power delivery to motor drives and cooling fans, making it central to the reliable and safe operation of variable frequency drives (VFDs) and other DC drive applications. Its compatibility with multiple GE drive platforms adds to its versatility, allowing engineers to use this board across a broad range of industrial applications, from manufacturing to process control.

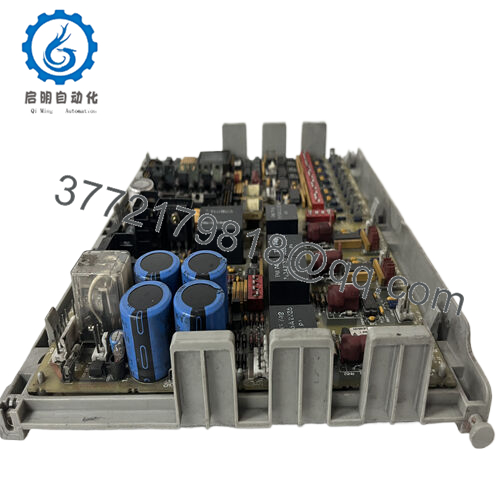

Technically, the DS200DCFBG1LC offers durable construction and precise feedback circuit design ideal for industrial settings. The VCO circuits output frequency ranges from 0 to 500 kHz depending on input voltage, facilitating high-resolution feedback signals for monitoring voltage levels. The board supports multiple feedback channels, providing comprehensive data for system diagnostics and control. DIP switches allow the scaling of voltage inputs, offering flexibility in tuning the feedback for different drive and power supply configurations. Its robust design tolerates industrial environmental conditions, ensuring consistent performance. Measuring approximately 170 mm by 105 mm by 32 mm and weighing about 1 kg, the board is compact enough for standard drive enclosures and control panels.

| Parameter | Value |

|---|---|

| Model | DS200DCFBG1LC |

| Manufacturer | General Electric (GE) |

| Product Type | DC Power Supply Feedback Board |

| Compatible Series | EX2000, DC2000, CB2000, FC2000, GF2000, ME2000, AC2000 |

| Function | Converts AC/DC input voltage to frequency feedback |

| Feedback Frequency Range | 0 to 500 kHz (nominal 250 kHz) |

| Dimensions | 170 mm x 105 mm x 32 mm |

| Weight | Approximately 1 kg |

| Mounting | Enclosure panel or drive housing |

| Voltage Input | 38 VAC, 115 VAC, and 24 VDC (control power transformer) |

| Diagnostic Test Points | Provided for oscilloscope frequency-to-voltage testing |

| Scaling Adjustment | DIP switches for voltage input scaling |

- DS200DCFBG1BLC

The DS200DCFBG1LC integrates closely with other drive system boards, such as the SDCC/LDCC feedback and control communication boards, enhancing coordinated operation of GE drive installations. This interplay between modules ensures precise power control and stable motor performance.

Installation requires secure mounting inside the drive enclosure with proper electrical connections to the control power transformer and relevant signal wiring. The environmental conditions within the enclosure should be free from excessive dust and moisture. Regular inspections should include checking feedback signal integrity via diagnostic test points and ensuring DIP switch settings correspond to system configuration. Routine monitoring helps maintain optimal drive performance and identifies potential issues before failures occur.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626