Description

The General Electric DL-1200 is a highly versatile and durable device that serves as a critical link between remote field devices and central control systems. It is designed to interface with various sensors, actuators, and other field devices, collect data, and transmit it to monitoring and data acquisition (SCADA) systems or programmable logic controllers (PLC) through various communication networks.

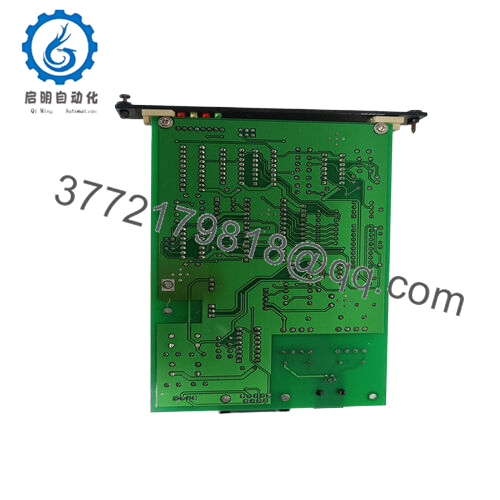

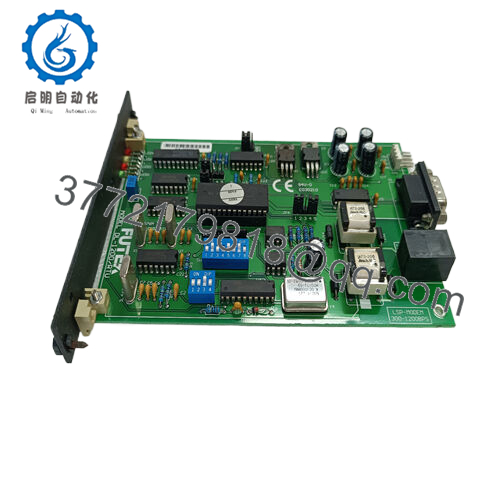

DL-1200 RTU

This RTU is equipped with multiple communication interfaces, including serial ports, Ethernet, and wireless options such as cellular or RF, which can adapt to different network environments. It supports industry standard protocols such as Modbus, DNP3, and IEC 60870-5-101/104, ensuring compatibility with existing infrastructure. RTU processes incoming data from field devices, performs local control functions when needed, and then packages and sends the data to the central control system. It can also receive control commands from the central system and execute them on connected field devices, enabling remote operation and adjustment.

DL-1200 RTU

Technical specifications:

Model numberDL-1200

Brand General Electric (GE)

Type: Remote Terminal Unit (RTU)

Input voltage 10-30 VDC

Working temperature range -40 ° C -70 ° C

Installation method: DIN rail or panel installation

Size 150mm x 100mm x 60mm

Weight 0.7 kg

Interface/Bus Serial Port (RS-232/RS-485), Ethernet, Wireless (Cellular, RF)

Compliance with CE, RoHS, UL

Supports protocols Modbus, DNP3, IEC 60870-5-101/104

I/O channels [specified quantity, e.g. up to 32 digital inputs, 16 digital outputs, 8 analog inputs]

Data storage capacity [provides capacity, such as up to 1 GB

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

DL-1200 RTU

Main features and advantages:

This device is designed to withstand extreme environmental conditions, ensuring reliable operation in harsh climates, dusty environments, and high electrical interference areas. This durability reduces the frequency of equipment failures, lowers unexpected downtime, and improves overall production efficiency.

The ability of RTU to support multiple communication protocols and interfaces simplifies system integration, making it easy to integrate into existing automation settings. Its data recording and processing capabilities reduce the burden on the central control system by preprocessing and storing data locally, achieving more efficient data management. The real-time data transmission and remote control functions provided by the General Electric DL-1200 enable operators to quickly respond to changes in conditions in remote areas, improve operational efficiency, and reduce the risk of expensive accidents. The built-in diagnostic function improves maintenance efficiency, actively identifies and solves potential problems, further extends the service life of the equipment, and reduces long-term maintenance costs.

DL-1200 RTU

Application areas:

In the power grid industry, it is used to monitor and control remote substations, transformers, and distribution equipment. RTU collects data on electrical parameters such as voltage, current, and power factor, and transmits it to the central control room. It also enables remote switching of circuit breakers and reclosers, ensuring stable and efficient operation of the power grid.

In the mining industry, as operations are typically carried out in remote and rugged terrain, the General ElectricDL-1200is deployed to monitor and control equipment such as conveyor belts, crushers, and ventilation systems. It allows real-time monitoring of device performance, detection of faults, and remote adjustment of operating parameters, improving safety and production efficiency. In addition, in environmental monitoring applications, RTUs can be connected to sensors that measure air quality, water quality, and weather conditions in remote areas, collecting and transmitting data for analysis and environmental management.

DL-1200 RTU

Related products:

General Electric DL-1500 RTU: Upgraded version with stronger processing capabilities and more I/O channels, suitable for larger and more complex remote monitoring and control applications.

General Electric DL-1000 RTU: An economical alternative product with basic RTU functionality, suitable for smaller scale or lower requirement remote operations.

General Electric DL-1200-H RTU: Designed for continuous high load operation in high-temperature environments with enhanced heat dissipation capabilities.

General Electric DL-1200-R RTU: Redundant model with dual channel operation, providing higher reliability and ensuring uninterrupted operation in case of component failure.

General Electric DL-1200-S RTU: Designed specifically for high-speed data transmission applications, providing faster communication rates and real-time data processing for applications that require immediate response.

General Electric DL-1200-C RTU: Built in security features such as data encryption and access control to meet the strict security requirements of critical infrastructure applications.

Installation and maintenance:

It is crucial to carefully plan and deploy according to the specific requirements of remote monitoring and control applications before installing the General Electric DL-1200 RTU. Verify whether the input voltage provided to the RTU is within the specified range to avoid damage. Assess communication requirements and select appropriate interfaces and protocols based on existing network infrastructure and connected on-site devices. Ensure that the installation location provides sufficient protection against environmental factors such as moisture, dust, and extreme temperatures.

During the configuration process, accurately set communication parameters, including IP address, baud rate, and protocol settings. Configure I/O channels based on the connected sensors and actuators, and define data recording and transmission plans according to application requirements. Equally important is to use appropriate passwords and access controls to protect the RTU from unauthorized access.

For continuous maintenance, regularly monitor the diagnostic information of RTUs, which can be remotely accessed through communication interfaces. These pieces of information can provide early warning of potential issues, such as communication failures, power problems, or equipment malfunctions. Regularly check physical connections, including cables and connectors, to ensure they are secure and undamaged. Perform routine data integrity checks to verify the accuracy of the collected and transmitted data. If any problems arise, please refer to the detailed troubleshooting guide provided by General Electric to promptly identify and resolve the issue.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626