Description

In the expansive landscapes of utility networks and remote operations, where scattered assets demand vigilant oversight amid unpredictable conditions like remote pipelines or offshore platforms, engineers wrestle with the fragility of data links that can falter under distance, interference, or isolation. The GE DL-1200 rises as a steadfast remote terminal unit (RTU), engineered to bridge those gaps in industrial automation by delivering unwavering data aggregation and control from the fringes of your system. Picture a vast water distribution grid: sensors scattered across kilometers report flow anomalies, but without a dependable relay, those insights dissolve into latency or loss, sparking inefficiencies or breaches in compliance. This RTU counters that by harvesting analog and digital I/O signals in real time, processing them locally for edge decisions, and streaming polished telemetry back to central SCADA hubs—securing process control without the drag of constant polling. It’s a linchpin in high reliability scenarios, such as oil and gas fields where harsh weather erodes cabling, or power substations chasing grid stability amid renewables’ flux. By centering on the practitioner’s drive for modular integration, the GE DL-1200 demystifies remote deployments, letting teams extend coverage without bespoke gateways or endless troubleshooting. In wastewater treatment spreads, it shines during storm surges, fusing sensor feeds to preempt overflows while enduring submersion risks. Far from a mere data hopper, it’s a resilience builder, trimming the downtime from signal dropouts that plague legacy setups. For evaluators charting paths in distributed architectures, the GE DL-1200 clicks because it fuses scalability with protocol fluency, paving a straightforward upgrade to fortified process control that honors standards like IEC 61850 sans ecosystem upheavals. Whether extending a municipal telemetry net or hardening a mining conveyor chain, it arms operations with the continuity to turn dispersed challenges into unified command.

- DL-1200 RTU

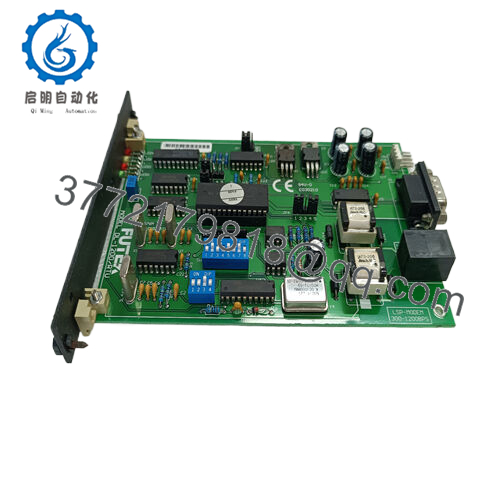

The GE DL-1200 anchors as a field-hardened RTU in GE’s grid and industrial control suites, pulling in raw field intelligence and meting it out to supervisory layers with minimal distortion. Rack it into a 19-inch enclosure, and it awakens: terminal blocks ingest up to dozens of DI/DO/AI/AO points from transducers and switches, then leverage embedded logic to timestamp, filter, and batch the haul before pushing via serial or Ethernet ports to master stations. Perched at the automation stack’s outpost—flanking sensors yet feeding the DCS core—it quells propagation risks like voltage sags or EMI bursts, ensuring payloads arrive intact for orchestration. In redundant meshes, it echoes states to mates over DNP3 links, enabling hot-standby swaps that mask faults in under a cycle, ideal for apps where a blip cascades to blackouts. Diagnostics weave in subtly, with onboard logs that snapshot events and relay them through SNMP traps or HMI queries, granting foresight into drifts without cabling crawls. Mesh it with I/O expanders or gateway modules in the bay, and it populates the central historian with vetted streams, fluent in Modbus RTU/TCP to IEC 60870 for effortless ties to multivendor overlays. Its appeal stems from tactical simplicity; configuration via GE’s WorkStation software plots I/O maps and event triggers sans steep curves, condensing rollout from months to milestones. For sprawling installs mingling fiber and radio, the unit’s adaptive baud rates and encryption wrappers preserve chain integrity, nixing the havoc of unsecured hops. Broadly, it cements stratified flows—perimeter for capture, RTU for triage, apex for analytics—nurturing extensible fabrics that flex from lone outposts to constellation arrays. This synergy not only hastens anomaly pinning but also primes for over-the-air patches, syncing with tightening cyber postures.

| Specification | Details |

|---|---|

| Model Number | DL-1200 |

| Brand | GE (General Electric) |

| Type | Remote Terminal Unit (RTU) |

| Input Voltage | 24 V DC or 110/220 V AC |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | 19-inch rack-mountable |

| Dimensions | 400 mm × 250 mm × 150 mm |

| Weight | 5-10 kg |

| Interface/Bus | RS-232, RS-485, Ethernet |

| Compliance | CE, RoHS; IEC 61850 compatible |

| Supported Protocols | Modbus, DNP3, IEC 60870-5-101/104 |

| Typical Power Draw | 15-25 W |

Embracing the GE DL-1200 ushers in layers of fieldwork fortitude, as its rugged casing and wide thermal span shrug off the brunt of desert heats or arctic snaps—envision a pipeline stretch where frost heaves don’t fuzz pressure reads, sustaining leak hunts that avert spills and salvage schedules by days. This steadfastness feeds into foresight gains; by buffering events locally, it enriches SCADA views with context-rich logs, empowering shifts to anticipate valve hangs or meter fouls ahead of escalations, often stretching service intervals by halves. Deployment drudgery ebbs as well, with its rack-standard form slipping into legacy bays sans chassis swaps, weaving fresh nodes into proven webs via a config refresh over USB.

Uptime’s cadence holds firm, courtesy of dual-path comms that reroute around link hiccups, locking in polling cadences below 500 ms even as terrains vary—key for utilities threading renewables where flux demands unyielding sync. Upkeep evolves to vigilance lite; self-audits pulse health metrics to dashboards, spotlighting a loose contact in a glance over grid sweeps, which can halve response crews in far-flung grids. Built for the long haul with flash-backed storage and conformal guards, it vows fade-resistant duty that outpaces fragile peers, cementing capex in volatile frontiers. For visionaries plotting expansions, its protocol stack eases federation with edge AI, shielding from edicts like bolstered data sovereignty without asset stranding. In sum, the GE DL-1200 recasts remote nodes from liabilities to lifelines, dispensing the vigilance and versatility that elevate dispersed automation from survivable to superior.

The GE DL-1200 fortifies outposts in electric utility substations, where it tallies breaker statuses and voltmeter pulses to underpin load shedding, shoring up critical system uptime through thunderous storms and cyber probes that test grid nerves. In these process control environments, its protocol prowess juggles DNP3 bursts for swift relays, dodging desyncs that might unbalance a region. Swing to oil and gas pipelines snaking continental divides, and it corrals flow and pressure telemetry, dictating valve tweaks amid seismic tremors and methane mists where continuous uptime fuels quarterly quotas. The unit’s edge processing thwarts noise from stray welds, upholding I/O signal high reliability for breach-free patrols. Water utilities cap the triad, with the GE DL-1200 in pump houses tallying levels and chlorinators against flood pulses and algal blooms, enabling dial-back commands that curb waste in drought-prone basins. Traversing these used in power plants and process control environments, it conquers harsh conditions, magnifying high reliability for sectors honing resilience amid regulatory tides.

DL-1000 – Compact predecessor for lighter I/O loads in small-scale remote monitoring.

DL-1500 – Expanded variant with extra analog channels for dense sensor arrays.

D20 RTU – Entry-level GE RTU for basic telemetry in legacy utility ties.

iRTU – Modern iteration with integrated cybersecurity for high-threat grids.

MACS RTU – Modular add-on for I/O scaling in existing DL-series racks.

T40 RTU – Ruggedized cousin optimized for seismic zones in mining ops.

VMU-1200 – Voltage monitoring unit that complements DL-1200 for power apps.

SCU-100 – Serial communication extender for long-haul links with DL units.

Prior to bolting down the GE DL-1200, audit your comms backbone—RS-485 stubs need termination resistors matched to stub lengths over 100 m to curb reflections that garble DNP3 frames at baud peaks. Survey rack airflow too; slots under 10 cm clearance invite hotspots in dusty vaults, so fan trays or louvers pay dividends in sustained scans. Firmware currency counts—pull the baseline from GE’s portal and flash via Ethernet to align with your SCADA’s dialect, staving off parse errors that idle the stack. On the care circuit, trimestral port sweeps with a loopback plug verify handshake vigor, especially in conductive airs; resistance spikes past 200 Ω signal corrosion calling for dielectric grease. Semiannual logic runs, scripting mock alarms from a bench rig, probe event fidelity sans field pulls—chart latencies over 100 ms to sniff processor lag. In surge-prone pockets, inspect ground bonds yearly; potentials north of 1 V phase-to-earth invite transients that skew analogs. These aren’t rituals—they’re the calibrated checks that anchor the RTU’s output, unburdening your watch to strategy over salvage.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626