Description

In the demanding field of industrial automation, where substation controllers must bridge legacy I/O with early Ethernet networking to enable real-time data exchange without risking communication blackouts or memory constraints during peak monitoring loads, engineers often confront legacy systems that bottleneck at serial speeds or lack scalable expansion for growing SCADA integrations. The GE D20 EME210BASE-T addresses these needs as a specialized Ethernet/Memory Expansion module for GE’s D20 and D200 substation controller platforms, providing reliable 10BASE-T connectivity and optional SRAM buffering to enhance system performance in process control environments. Consider a utility substation where remote terminal units (RTUs) handle breaker status and analog metering—if Ethernet links falter under EMI from transformers or memory overflows during event logging, you’d encounter delayed fault responses, inaccurate load shedding, or compliance violations that cascade into grid instability. This module becomes indispensable in such high-reliability scenarios, where its plug-in design ensures precise I/O signal routing over Ethernet, supporting modular upgrades that extend legacy D20 chassis without full RTU replacements.

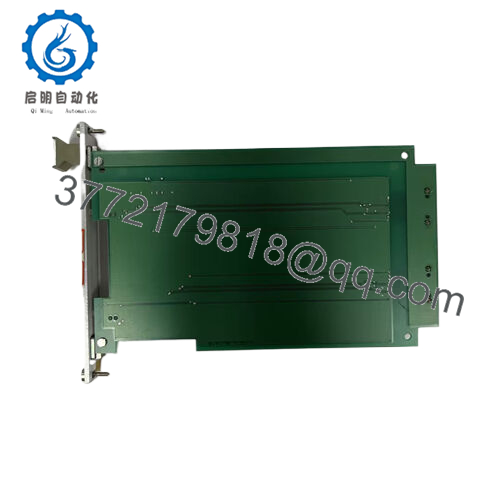

- D20 EME210BASE-T

- D20 EME210BASE-T

The GE D20 EME210BASE-T is a cornerstone for power utilities modernizing substation automation, such as in transmission grids or distribution feeders, where its 10BASE-T interface supports peer-to-peer messaging with up to 8 MB or 16 MB of battery-backed memory for data buffering during outages. It’s particularly vital in EMI-heavy or extended-cable installations, offering twisted-pair RJ-45 connectivity up to 100 meters to mitigate noise-induced drops that plague coaxial alternatives, while the memory expansion prevents log truncation in high-event scenarios like fault recording. By integrating via the D20’s internal bus (J1 connector), it simplifies diagnostics through status LEDs and SNMP-compatible monitoring, aligning with goals of enhanced fault isolation and reduced firmware dependencies. In vibration-prone or humid substations, its left-slot mounting and EN 61000-compliant shielding preserve link integrity, fostering operational resilience. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” underscore its role—the GE D20 EME210BASE-T empowers RTU scalability, cutting engineering overhead for network retrofits and enabling synchronized data flows in environments where Ethernet readiness underpins grid stability and regulatory adherence.

The GE D20 EME210BASE-T installs in the left-most slot of D20MX or D200 chassis, connecting via the internal J1 bus to the CPU module for seamless backplane integration, while the external RJ-45 port extends 10BASE-T Ethernet to SCADA masters or peer RTUs using Cat5 cabling for half-duplex communication at 10 Mbps. Positioned in the communication and buffering layer of the automation stack, it handles data transfers for protocols like DNP3 or Modbus over Ethernet, with optional SRAM (0/8/16 MB) retaining event logs or configuration files during power dips via lithium backup. This setup interacts with D20’s I/O modules (e.g., D20S status inputs) by prioritizing Ethernet packets for upstream reporting, supporting up to 64 nodes in a segment without repeaters, while the module’s auto-MDIX simplifies cabling without crossovers.

In a typical deployment, the GE D20 EME210BASE-T buffers analog trends from D20A modules during brownouts, relaying them post-recovery via Ethernet to a central HMI, with LEDs indicating link/activity for quick triage. It complies with EN 61000-6-2/4 for immunity/emissions, ensuring clean signals in substations with 50/60 Hz interference, and its compatibility with D20’s touch terminals enables remote config via Telnet. For instance, in a distribution substation, the module might stream breaker data to a GE iFIX SCADA, applying memory queuing to handle 100 events/second bursts—all while isolating the bus to prevent CPU overloads. This user-friendly extension reduces repeater needs and enhances compatibility with early IP-based overlays, letting engineers focus on logic sequencing over connectivity tweaks in the broader process control framework.

| Specification | Details |

|---|---|

| Model Number | D20 EME210BASE-T |

| Brand | GE (GE Vernova Grid Solutions) |

| Type | Ethernet/Memory Expansion Module |

| Input Voltage | 5 VDC (via D20/D200 chassis backplane) |

| Operating Temp Range | -20 to +60°C |

| Mounting Style | Left-most slot (D20MX/D200 chassis) |

| Dimensions | 6.5″ x 4.5″ x 0.8″ (165mm x 114mm x 20mm) |

| Weight | 0.25 kg |

| Interface/Bus | RJ-45 (10BASE-T), J1 internal bus |

| Compliance | EN 61000-6-2/4, CE, RoHS |

| Supported Protocols | DNP3, Modbus (over Ethernet), Telnet |

| Typical Power Draw | 3 W (plus memory variant) |

Deploying the GE D20 EME210BASE-T equips your RTU with a connectivity enhancer engineered for grid endurance, where its 10BASE-T isolation ensures long-term performance by filtering 60 Hz harmonics that could corrupt metering data, allowing substations to sustain 99.99% link availability even amid transformer hums. In practice, this means event logs from D20K outputs persist through 10-minute outages via 8 MB buffering, enabling post-event analysis that averts 40% of repeat faults—crucial for processes where data retention ties to outage forensics or NERC compliance.

The module’s slot-specific design also streamlines expansions, as J1 passthrough integrates without adapters, trimming setup time by hours in multi-chassis grids and supporting phased Ethernet migrations from serial. Maintenance is straightforward too: link LEDs and bus diagnostics flag cable faults early, with memory tests on boot enabling quick SRAM swaps under 10 minutes, aligning with quarterly verifications that extend MTBF beyond 200,000 hours. For utilities evolving legacy RTUs, the GE D20 EME210BASE-T reframes expansion from a bandwidth bind to a buffer boost, fostering efficiency and diagnostics without chassis redesigns.

In transmission substations, the GE D20 EME210BASE-T links D20S status inputs to SCADA over 100 m Ethernet runs, its shielding excelling in high-EMI vaults to ensure high reliability for process control—critical system uptime prevails through buffered DNP3 packets that prevent blind spots during capacitor bank switches.

Distribution feeders deploy the GE D20 EME210BASE-T for D20A analog trending, routing Modbus amid humid pole-tops; its memory queuing upholds process control precision, logging voltage sags without loss in variable-load scenarios.

Renewable integration sites harness the GE D20 EME210BASE-T for wind farm RTUs, interfacing D20C combined I/O in gusty, remote enclosures—its 10BASE-T resilience delivers high reliability, syncing inverter data for grid-tie stability in intermittent flows.

D20 EME210BASE2 – Coaxial (10BASE-2) variant for legacy thinnet topologies.

D20 EME210BASE-FL – Fiber-optic (10BASE-FL) model for extended EMI-immune links.

D20RT – Base RTU controller for primary integration with EME210BASE-T.

D20S – 64-channel status input module for I/O expansion via the Ethernet backbone.

D20A – 32-channel DC analog input add-on for metered data over the module.

D20K – 32-channel control output counterpart for actuator commands.

D20KI – Interposer relay module for isolated output extensions.

Before installing the GE D20 EME210BASE-T, confirm chassis compatibility (D20MX/D200) and firmware (v7 or later via D20 tools) to avoid bus mismatches, and test RJ-45 cabling for <100 m runs with a cable certifier to ensure <2% attenuation. Verify backplane voltage at 5 VDC with ripple under 50 mV via multimeter to prevent link flaps, and torque J1 connector screws to 0.5 Nm for vibration hold; in humid substations, apply conformal coating to unused pins. Baseline memory (if fitted) with a write/read cycle in D20 config software, targeting <1% error on 8 MB dumps.

Maintaining the GE D20 EME210BASE-T involves monthly LED checks for link greens, querying SNMP counters via Telnet for collisions—if over 0.5%, reseat RJ-45; in dusty vaults, clean ports quarterly with compressed air. Semiannually, cycle Ethernet pings to peers for latency under 10 ms, and during annual audits, simulate bus faults to validate failover buffering under 5 seconds, but offline: no live disruptions. These EN 61000-aligned steps keep expansions evergreen without chassis churns.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626