Description

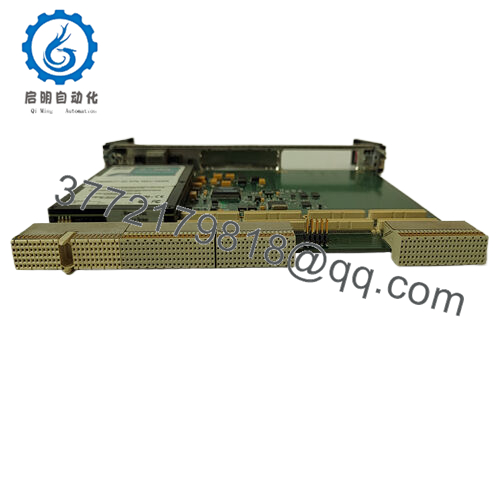

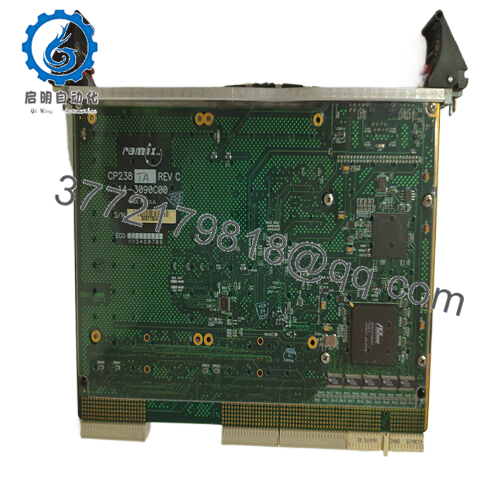

Product Model: GE CP238TA

Product Brand: GE (General Electric)

Product Series: GE Fanuc Series 90-30 PLC

Product Features:

- 8-channel analog output module for Series 90-30 controllers

- High-resolution current and voltage outputs

- Designed for precision process control and automation systems

- Reliable operation in industrial and utility environments

- CP238TA

Applications & Industry Context

Industrial processes depend on accurate analog output signals to control valves, drives, actuators, and instrumentation. The GE CP238TA was designed exactly for that purpose—delivering stable and precise analog signals from the Series 90-30 PLC to the field.

In sectors like chemical manufacturing, water treatment, oil and gas, and discrete manufacturing, engineers rely on modules like the GE CP238TA to translate digital control logic into continuous analog outputs that keep processes balanced and efficient. From controlling steam valves in a turbine system to modulating speed on a variable-frequency drive, this module helps maintain the link between digital intelligence and real-world behavior.

The GE CP238TA supports multiple output ranges, making it versatile across a variety of applications. Whether adjusting flow control valves or providing reference voltages to instrumentation amplifiers, its performance is consistent and repeatable.

In water and wastewater plants, for instance, operators use the module to maintain tank levels or chlorine dosing rates with smooth, analog accuracy. In packaging lines, it helps regulate motor torque and conveyor speed, ensuring that production stays synchronized.

Reliability in these applications isn’t optional—it’s essential. That’s why engineers value the GE CP238TA for its rugged construction, noise immunity, and predictable behavior under challenging plant conditions.

Product Role & System Fit

Within a GE Fanuc Series 90-30 PLC system, the GE CP238TA serves as the bridge between the controller’s CPU and field devices that need analog control signals. It converts the digital control commands generated by the PLC logic into current or voltage outputs suitable for actuators and process devices.

The Series 90-30 architecture allows flexible expansion: digital I/O, analog I/O, communications, and specialty modules share the same backplane. The GE CP238TA fits right into this modular environment. Once installed in an available slot, it communicates through the PLC’s backplane bus, receiving data words from the CPU and outputting the corresponding analog signals in real time.

Its configuration is managed via the same programming tools used for the entire Series 90-30 line—typically Proficy Machine Edition or older Logicmaster 90 software. Parameters like output range selection, scaling, and update rate can be tailored to the specific application, ensuring compatibility with almost any type of transducer or actuator.

For integrators, the module’s compact form factor and consistent wiring layout reduce panel space requirements and simplify system design. The GE CP238TA’s design philosophy is classic GE Fanuc—modular, dependable, and built for longevity.

Technical Features & Benefits

The GE CP238TA offers precise analog performance with industrial-grade reliability. Each channel can output either voltage or current, selectable to meet system requirements. This makes it highly adaptable for mixed-signal control tasks.

Key highlights include:

- High Resolution: Typical 12-bit or better digital-to-analog conversion ensures fine signal granularity and smooth control transitions.

- Multiple Output Ranges: Selectable ranges such as 0–10 V, ±10 V, 4–20 mA provide flexibility for different field instruments.

- Channel Isolation: Designed to minimize cross-talk and protect the PLC from field disturbances.

- Field-Proven Durability: Components are rated for extended temperature ranges, ensuring consistent operation even in unconditioned enclosures.

- Easy Diagnostics: LED indicators show module and channel status at a glance, reducing troubleshooting time.

- Hot Swappability: Within properly configured racks, modules can often be replaced without powering down the entire system—minimizing downtime.

In process control, precision often defines product quality. The GE CP238TA supports that need with stable outputs that resist drift, temperature influence, and electrical noise. Over time, this stability translates directly into reduced maintenance costs and tighter process control loops.

Technical Specifications

| Specification | Description |

|---|---|

| Model | GE CP238TA |

| Series | GE Fanuc Series 90-30 PLC |

| Function | Analog Output Module |

| Channels | 8 analog output channels |

| Output Ranges | 0–10 V, ±10 V, 0–20 mA, 4–20 mA (selectable) |

| Resolution | 12 bits (typical) |

| Output Accuracy | ±0.1 % of full scale |

| Update Rate | ≤ 5 ms per channel |

| Isolation | Channel-to-PLC isolation > 1500 VDC |

| Power Consumption | ~250 mA @ 5 V DC |

| Operating Temperature | 0 °C to +60 °C |

| Mounting | Series 90-30 rack mount (backplane) |

| Dimensions | Approx. 130 mm × 35 mm × 120 mm |

| Weight | Around 0.4 kg |

Installation & Maintenance Insights

Installing the GE CP238TA follows the standard Series 90-30 procedure: ensure the rack is de-energized, align the module’s backplane connector, and secure it with the retaining clips. Correct orientation is vital—forcing the module can damage the pins.

Each channel’s terminal block should be wired using shielded, twisted-pair cables to minimize noise pickup. When wiring current loops, a dedicated power supply and proper grounding practices ensure accurate readings and prevent ground loops.

After installation, system software is used to configure channel ranges and scaling factors. Output verification can be done with a multimeter or process calibrator before commissioning.

Maintenance requirements are low. Visual inspection of terminal connections during scheduled shutdowns and periodic output verification against calibration standards will keep the GE CP238TA performing accurately for years. Its robust design means that drift and failure are rare, even in high-vibration or temperature-fluctuating environments.

Should replacement ever be necessary, the module’s modular backplane design allows fast swap-outs—simply remove the faulty unit and insert a new one, retaining all configuration data within the PLC CPU.

Related Models

- GE IC693ALG223 – 4-channel analog output module for Series 90-30

- GE IC693ALG221 – 2-channel voltage output version

- GE IC693ALG390 – High-resolution analog input module

- GE IC693MDL240 – Discrete output module for relay control

- GE IC693PCM301 – Communications coprocessor module

- GE IC693ALG392 – 16-channel analog input module

- GE IC693MDL940 – High-density 24 V DC output card

- GE IC693ALG324 – Mixed input/output analog module

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626