Description

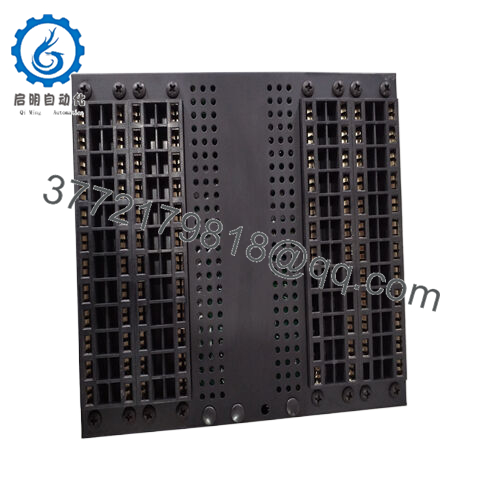

The GE 760-P5-G5-S5-HI-A20-R is a high-end feeder management relay from the GE Multilin 750/760 series, designed to deliver comprehensive protection, control, and monitoring for industrial and utility power distribution feeders. It is widely used in utility substations, industrial plants, and commercial facilities where reliable feeder protection and advanced monitoring capabilities are critical for operational safety and efficiency.

This relay features five 5A phase current inputs and five 5A zero-sequence current inputs, providing precise fault detection and protection for power feeders. It also includes a 5A sensitive ground current input, enhancing earth fault detection accuracy. The GE 760-P5-G5-S5-HI-A20-R supports a wide control power supply range from 88 to 300 V DC or 70 to 265 V AC, offering flexibility in various power system configurations. Its eight 4-20 mA analog outputs allow for extensive monitoring and control interface options, while the large 40-character alphanumeric LCD provides user-friendly real-time status and fault visualization.

The relay integrates advanced features such as oscillography, waveform capture, event and fault logging, and actual value metering for parameters like voltage, current, power, and frequency. Enhanced communications are supported, including Ethernet 10BaseT for remote access and control, with optional features such as breaker closed red LED indicators to simplify system status checks. The robust and intuitive interface facilitates easier programming and diagnostics, reducing setup time and maintenance effort.

- 760-P5-G5-S5-HI-A20-R

- 760-P5-G5-S5-HI-A20-R

| Parameter | Value |

|---|---|

| Model | GE 760-P5-G5-S5-HI-A20-R |

| Manufacturer | General Electric (GE Multilin) |

| Product Type | Feeder Management Relay |

| Phase Current Inputs | Five 5A inputs |

| Zero-Sequence Current Inputs | Five 5A inputs |

| Sensitive Ground Current Input | 5A input |

| Control Power Supply | 88–300 V DC / 70–265 V AC |

| Analog Outputs | Eight 4-20 mA outputs |

| Display | 40-character alphanumeric LCD |

| Communication | Ethernet 10BaseT, optional other protocols |

| Weight | Approximately 8 lbs |

| Operating Temperature | –40°C to +80°C |

| Features | Oscillography, waveform capture, event logging, advanced protection algorithms |

| Breaker Status Indicator | Red LED breaker closed indicator |

Related GE modules and systems often paired with the 760-P5-G5-S5-HI-A20-R include:

GE 750-P5-G5-S5-HI-A20-R-E – Enhanced version of the 750 feeder relay with advanced display features.

GE 760-P5-G5-S5-HI-A20-R-T – Variant with Ethernet and enhanced communication options.

GE Multilin 850 – Substation automation relay integrating multiple feeder protection and control functions.

GE 369 Motor Protection Relay – Motor management solution often used alongside feeder relays for comprehensive plant protection.

GE Multilin Controllers and SCADA Interfaces – Systems compatible with 750/760 relays for integrated power management.

Installation of the GE 760-P5-G5-S5-HI-A20-R requires secure mounting typically in standardized 19-inch relay racks or cubicles, with attention to environmental protection and wiring organization. The relay must be connected to power transformers, current transformers, and the control power supply within strict voltage and wiring standards to ensure correct and safe operation. Grounding and EMI shielding practices are critical due to the relay’s sensitivity to accurate current measurement and protection operation.

Maintenance best practices include regular firmware updates using GE’s EnerVista software suite, monitoring event and fault logs for early detection of issues, and scheduled physical inspections of connections and environmental conditions within relay panels. The large LCD interface eases diagnostics during routine checks, and alarms can be configured for critical parameter warnings.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626