Description

GE 369B1859G0022 is a high-performance steam turbine control module. It is an important component of GE’s advanced steam turbine control system. Functionally speaking, it serves as the interface hub between on-site sensors and actuators and advanced monitoring and control systems. It aims to manage and control the complex control loop of steam turbine operation.

369B1859G0022

In the architecture of the turbine control system, GE 369B1859G0022 receives real-time data from various sensors, such as proximity probes (used to monitor the position of turbine components), temperature sensors (crucial for ensuring that the turbine does not overheat), and pressure sensors (used to control fluid pressure in the system). Then, it processes these raw data and generates accurate control signals, which are sent to actuators such as valves and drivers. These signals precisely adjust the operation of the turbine, such as opening or closing valves to regulate the flow of steam or fuel.

369B1859G0022

Main features and advantages:

In terms of functional performance, it adopts highly advanced PID (proportional integral derivative) control and adaptive tuning algorithm. These algorithms enable them to maintain the turbine speed within an extremely precise range of ± 0.1% of the set value when the turbine load changes rapidly. This precision is crucial as it reduces mechanical stress on turbine components, thereby extending their service life. It also optimizes energy efficiency, which is an important cost saving factor for energy intensive industries.

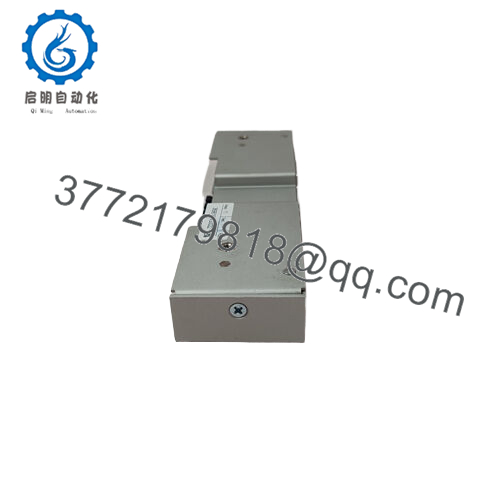

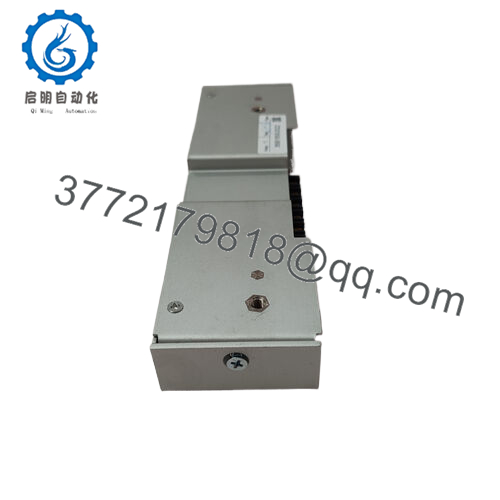

The hardware design of GE 369B1859G0022 is extremely robust. It adopts a reinforced metal shell that can withstand the harsh conditions commonly found in industrial environments. In addition, it also has a moisture-proof coating, and its components can withstand impact and vibration, complying with standards such as IEC 60068-2-6. This makes it suitable for offshore platforms, refineries, and other environments with extreme operational requirements. The module is compact in size, measuring 300 millimeters (height) x 200 millimeters (width) x 100 millimeters (depth), and weighs 3.5 kilograms, making it easy to install in various control cabinets. It adopts a standard 19 inch rack mounting system, simplifying the integration process.

Compatibility is another strength of GE 369B1859G0022 . It supports multiple communication interfaces, including Ethernet, RS-485, and PROFIBUS DP. This enables seamless integration with GE’s own Proficy software suite, enabling remote configuration, diagnostics, and firmware updates. In addition, its open communication protocols such as Modbus and PROFIBUS also facilitate integration with third-party systems, providing users with the flexibility to build more customized control systems without overly relying on proprietary solutions.

In terms of long-term reliability, GE369B1859G0022 has a redundant architecture. It is equipped with a dual core processor and redundant power input. When a component fails, dual core processing ensures that the module can continue to operate, while redundant power supplies prevent interruptions caused by power issues. Its dual Ethernet ports support network failover, improving the reliability of the entire system in critical mission applications. This module also has real-time self diagnostic function, which can continuously monitor processor load, memory usage, and communication integrity. The fault code will be immediately transmitted to the DCS (Distributed Control System), and the LED indicator lights on the module provide visual status updates, which simplifies the troubleshooting process and shortens the Mean Time to Repair (MTTR).

369B1859G0022

Technical specifications:

Model 369B1859G0022

Brand GE

Type: Turbine Control Module

Input voltage 24 V DC ± 10%

Communication interface Ethernet RS – 485、PROFIBUS DP

Physical dimensions: 300mm (height) x 200mm (width) x 100mm (depth)

Weight 3.5 kilograms

Working temperature -25 ° C to+70 ° C

Installation method: Rack installation (19 inch standard)

Certification CE, UL, IEC 61131-2

Redundant support for dual core processors and redundant power input

Data storage: 512 MB flash memory, 256 MB RAM

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

369B1859G0022

Application areas:

In power plants, whether they are large thermal power plants or modern combined cycle power plants, they highly rely on steam turbines to convert energy into electricity. GE 369B1859G0022 plays a crucial role in it. In thermal power plants, steam turbines operate under extreme conditions of high temperature and pressure. The GE 369B1859G0022module can accurately regulate the steam flow entering the turbine blades, ensuring that the turbine rotates at a constant speed. This not only maximizes power output, but also helps maintain stability in connection with the grid. In gas-fired power plants, it controls the fuel air mixture supplied to the gas turbine, optimizes combustion efficiency, and reduces harmful emissions.

In the oil and gas industry, gas turbines are used for various purposes, such as powering compressors in pipelines. GE 369B1859G0022ensures the smooth operation of these turbines and prevents sudden changes in speed from causing pipeline pressure fluctuations or compressor failures. This is crucial for maintaining the continuous flow of oil and natural gas in long-distance pipelines.

369B1859G0022

Related products:

GE 369B1843G5003- Designed for applications with slightly different control requirements, it may be suitable for smaller turbine installations or scenarios with less complex control circuits.

GE Analog Input Module – can be paired with GE 369B1859G0022 to expand the system’s ability to receive and process analog signals from various sensors, enhancing overall data acquisition capabilities.

GE Relay Module – can be used to control high-power equipment in turbine control systems, complementing GE 369B1859G0022 which focuses on core control algorithms and data processing.

GE Digital Input/Output Module – Used to interface with digital devices in the system, enabling more precise control and monitoring of digital components in the turbine unit.

GE Communication Expansion Module – Modules with additional Ethernet ports or enhanced wireless communication capabilities can be used for expansion

The communication range of GE 369B1859G0022 is particularly suitable for large industrial factories that require long-distance data transmission.

Installation and maintenance:

Before installing GE 369B1859G0022 several factors need to be considered. The control cabinet for installing it should have appropriate dimensions to accommodate the module and ensure good ventilation. There should be sufficient space around the module for heat dissipation, as the module generates heat during operation. Grounding is crucial. Proper grounding connections help protect the module from surges and interference, ensuring its stable operation. The grounding resistance should be checked and ensured to be within the specified range.

In terms of maintenance, it is recommended to conduct regular visual inspections. Check the module at least once a month for any signs of physical damage, such as cracks in the casing or loose connections. Signal diagnosis should be conducted quarterly to ensure the accuracy of data received and transmitted by the module. This involves comparing the sensor data with the signals processed by the module. In addition, it is crucial to update the firmware of the module in a timely manner. GE will regularly release firmware updates, which may include bug fixes, performance enhancements, and new features. Updating firmware in a timely manner helps keep GE 369B1859G0022 in optimal operating condition.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626