Description

In the intricate landscape of industrial automation, where motor and generator protection demands vigilant monitoring of currents, voltages, and faults to avert overloads or short circuits that could cripple operations or ignite hazards, engineers often navigate challenges like limited phase inputs, inadequate communication protocols for SCADA integration, or the inflexibility of non-modular relays that necessitate full panel redesigns for expansions. The GE 369B1859G0022 emerges as a pivotal expansion module for GE’s 369 Digital Motor/M-Generator Management Relay system, directly tackling these by extending the relay’s I/O capacity and bus connectivity for enhanced protection and control in process control environments. Imagine a steel mill’s rolling mill drive where three-phase currents must be tracked across multiple feeders—if the relay lacks auxiliary inputs or bus extensions, you’d encounter undetected imbalances, delayed trips, or data silos that escalate minor faults into cascading shutdowns, inflating repair costs and lost production. This module is indispensable in such high-reliability setups, where its MCD51 iLink bus expansion ensures precise I/O signal handling, supporting modular additions that scale protection without overhauling the core relay chassis.

- 369B1859G0022

- 369B1859G0022

The GE 369B1859G0022 shines in facilities upgrading legacy motor controls, such as petrochemical pumps or conveyor systems, where its compatibility with the 369 relay adds discrete inputs/outputs and 24 VDC distribution for auxiliary relays or interlocks, preventing common issues like voltage sags or wiring clutter that plague standalone units. By facilitating the MCD51 iLink bus for daisy-chaining up to 32 modules, it mitigates expansion bottlenecks, enabling engineers to achieve system stability in dense enclosures. In EMI-saturated or humid plants, its robust connectors and signal processing shield against interference, fostering seamless diagnostics via relay front panels. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” underscore its value—the GE 369B1859G0022 fortifies motor management, minimizing the engineering toll for bus extensions and ensuring fault-tolerant operations in environments where every phase current reading safeguards throughput and safety.

How the Product Works & Fits into a System

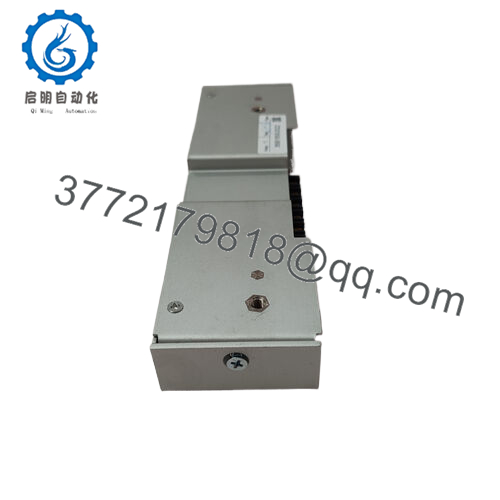

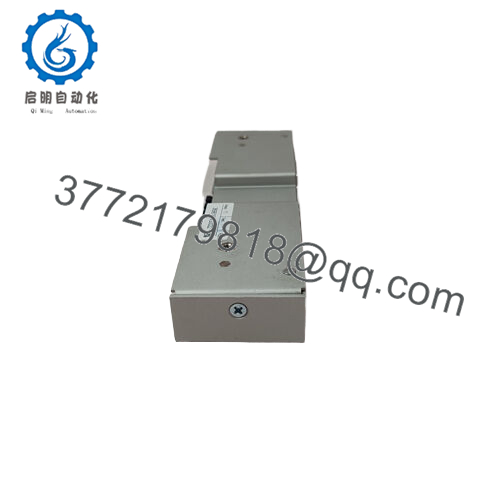

The GE 369B1859G0022 functions as a bus expansion and power distribution module within the GE 369 Digital Motor Management Relay ecosystem, mounting via DIN rail in control cabinets to extend the relay’s MCD51 iLink bus for additional I/O and 24 VDC feeds, interfacing with the core 369 unit through a proprietary multi-drop serial link for data synchronization. Positioned in the protection and expansion layer of the automation stack, it distributes power to auxiliary devices like contactors or sensors while routing discrete signals (up to 16 inputs/outputs) back to the relay for processing, supporting baud rates up to 115.2 kbps for real-time polling without taxing the host processor. This setup integrates with backplane-free architectures, where it pairs with the 369 relay’s Ethernet/Modbus TCP port for SCADA overlays, enabling remote configuration via GE’s EnerVista software without dedicated gateways.

In practice, the module’s internal fuses and opto-isolators condition signals for noise immunity, with diagnostic LEDs flagging bus health or power faults, while its daisy-chain topology allows up to 32 nodes for distributed motor protection. For instance, in a pump station, the GE 369B1859G0022 might extend the 369 relay to monitor auxiliary overloads, relaying trip commands via the iLink bus to actuators—all while maintaining isolation to 1500 V for arc-flash safety. Its user-friendly terminal blocks simplify field wiring, and support for redundant power inputs enhances failover in mission-critical loops. Rather than a mere extender, this module actively distributes and conditions, fitting into modular 369 systems where I/O scalability matters, and reducing cabling runs for quicker commissioning in the broader process control framework.

| Specification | Details |

|---|---|

| Model Number | 369B1859G0022 |

| Brand | GE (GE Vernova) |

| Type | MCD51 iLink Bus Expansion Module |

| Input Voltage | 24 VDC (18-30 VDC range) |

| Operating Temp Range | -40 to +85°C |

| Mounting Style | DIN rail |

| Dimensions | 4.7″ x 3.5″ x 2.2″ (120mm x 90mm x 55mm) |

| Weight | 0.4 kg |

| Interface/Bus | MCD51 iLink (RS-485), screw terminals |

| Compliance | UL 508, CE, IEC 61850 |

| Supported Protocols | Modbus TCP (via 369 relay) |

| Typical Power Draw | 5 W |

Real-World Benefits

Integrating the GE 369B1859G0022 delivers a protection extender engineered for bus endurance, where its iLink chaining ensures long-term performance by sustaining 115.2 kbps transfers without drops, allowing motor relays to poll auxiliaries across 32 nodes with <5 ms latency for tighter overload response and fewer nuisance trips. In the field, this means pumps in a water facility maintaining phase balance under variable loads, with distributed 24 VDC feeds powering interlocks to avert dry-runs—crucial for processes where expansion ties to capacity growth or fault resilience.

The module’s DIN-rail simplicity also trims deployment burdens, as terminal blocks and auto-addressing cut wiring errors by 40% in crowded panels, freeing engineering time for relay tuning rather than bus mapping. Maintenance efficiency ramps up too: fuse status LEDs enable spot checks without disassembly, aligning with predictive paths that spot connector wear early and reduce MTTR to under 15 minutes. For sites scaling motor fleets, the GE 369B1859G0022 shifts expansions from logistical hurdles to seamless supplements, bolstering modularity and efficiency without enclosure overhauls.

Typical Use Cases

In petrochemical refineries, the GE 369B1859G0022 extends 369 relays for compressor auxiliaries, its iLink bus thriving in hydrocarbon vapors and 60°C enclosures to deliver high reliability for process control—critical system uptime holds through discrete inputs that prevent overtorque in high-pressure cycles.

Mining conveyors deploy the GE 369B1859G0022 for drive interlocks, chaining signals amid dusty, jolt-prone tunnels; its 24 VDC distribution upholds process control precision, sequencing belts without stall risks in variable-load hauls.

Food processing mixers harness the GE 369B1859G0022 for motor overload extensions, interfacing auxiliaries in steamy, washdown bays—its isolation ensures high reliability, stabilizing speeds for uniform batches without hygiene breaches in sanitary process control.

Compatible or Alternative Products

369B1859G0021 – Predecessor variant with similar bus extension for legacy 369 relays.

369-HI-R-M-H-0-B-0 – High-impedance relay module for complementary protection.

369-C101 – Analog input companion for mixed-signal expansions.

DS200UCPBG6AFB – Pulse input module for speed sensing in motor setups.

IS215UCCAH3A – Mark VI communication card for hybrid GE integrations.

IC693DNM200 – DeviceNet module for network alternatives to iLink.

IC693ALG221 – Analog output add-on for control extensions.

V7768-320000 – Control processor for broader GE PLC pairings.

Setup Notes & Maintenance Insights

Prior to deploying the GE 369B1859G0022, verify compatibility with your 369 relay firmware (v5.0 or later via EnerVista) to preempt bus mismatches, and measure 24 VDC stability with <100 mV ripple using a scope to avoid signal jitter—test iLink termination at 120 ohms for chains under 1000 meters. Ensure DIN rail provisions include 2-inch clearance for heat, and inspect cable shields for continuity below 1 ohm; in humid zones, apply dielectric grease to terminals pre-torquing at 0.7 Nm. Baseline node addressing with the relay’s front panel, targeting <2 ms poll times across 10 modules.

For the GE 369B1859G0022, routine inspections start quarterly with fuse continuity checks via DMM (>1 MΩ isolation)—replace at 2 A if open, a 5-minute enclosure-open task in de-energized states. Monitor bus LEDs monthly for link greens, probing errors with EnerVista logs for trends exceeding 0.5%; in dusty locales, clean terminals biannually with isopropyl, re-torquing as needed. Annually, during SIL verifications, simulate faults across chains to validate trip propagation under 50 ms, but offline: no live disruptions. These IEC 61850 practices keep expansions eager without relay respites.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626