Description

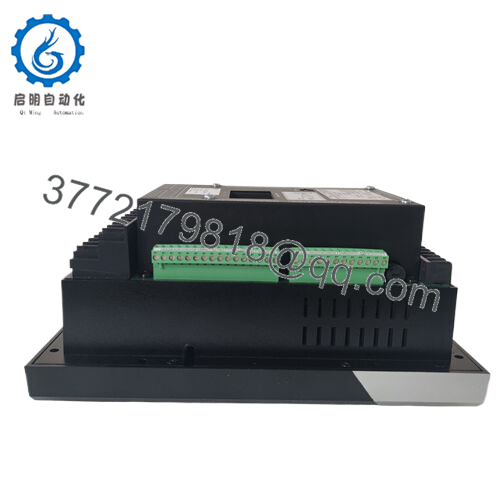

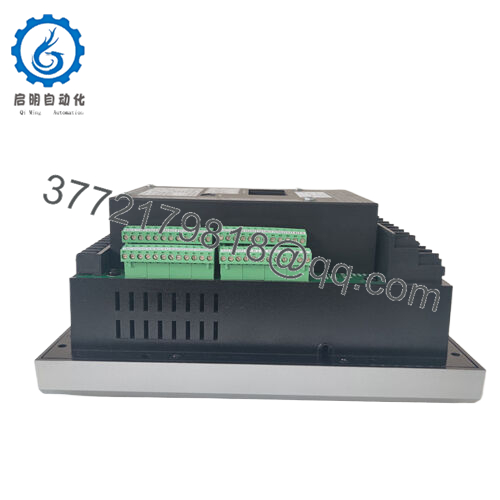

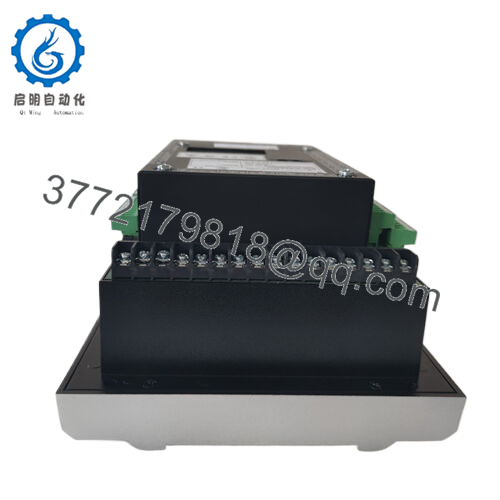

The GE 369-HI-R-M-0-0-0-E is a digital motor protection relay designed to deliver advanced protection and control for medium-sized AC motors and their mechanical systems. Used extensively in industrial automation across sectors like power generation, manufacturing, mining, and water treatment, this relay addresses critical challenges in motor management, including fault detection, overload protection, and operational analytics. The GE 369-HI-R-M-0-0-0-E is especially prized for its adaptive protection capabilities that learn and optimize settings based on motor characteristics such as inrush current and cooling rates. This makes it invaluable in environments where protecting expensive motor assets from thermal, electrical, and mechanical faults is essential to minimize downtime and enhance operational efficiency.

At its core, the GE 369-HI-R-M-0-0-0-E acts as an intelligent motor management system within distributed control and protection architectures. It integrates a wide range of protection features such as phase reversal detection, stall/jam protection, undervoltage and overvoltage monitoring, thermal overload, and current unbalance detection. Incorporated metering functions deliver real-time data on voltage, current, power, energy, frequency, and temperature through optional RTDs (Resistance Temperature Detectors). The relay interfaces via multiple communication ports, including RS232, multiple RS485 ports, and Ethernet, allowing seamless integration with supervisory control and data acquisition (SCADA) systems and automation networks via protocols like Modbus RTU and TCP/IP. Engineers benefit from its user-friendly 40-character LCD display and keypad for programming and diagnostics, along with EnerVista 369 software support for enhanced visualization and configuration.

From a technical standpoint, the GE 369-HI-R-M-0-0-0-E supports a wide control power voltage range of 50–300 VDC or 60–265 VAC, making it compatible with diverse industrial power supplies. It includes optional 12 RTD inputs to monitor motor temperatures, allowing early detection of overheating issues. The relay is equipped with four output relays and several digital inputs for alarm, trip, and control signaling. Designed for harsh industrial environments, it offers a rugged case and robust communication flexibility with optional interfaces including Profibus DP, DeviceNet, and Fiber Optic ports. Its internal memory stores event records, oscillography, and motor starting data logger information for comprehensive fault analysis.

- 369-HI-R-M-0-0-0-E

- 369-HI-R-M-0-0-0-E

| Parameter | Value |

|---|---|

| Model | GE 369-HI-R-M-0-0-0-E |

| Manufacturer | General Electric (GE) |

| Product Type | Digital Motor Protection Relay |

| Control Power Voltage | 50–300 VDC / 60–265 VAC |

| Operating Temperature | Industrial range (specific range varies) |

| Dimensions | Approximate size: 10 x 15 inches (front panel) |

| Weight | Not explicitly specified |

| Communication Ports | 1 x RS232 front, 3 x RS485 rear, Ethernet optional |

| Protocols Supported | Modbus RTU, Modbus TCP/IP, Profibus DP optional |

| Inputs | 3-phase CT inputs, 12 RTD temperature inputs (optional) |

| Outputs | 4 programmable relay outputs |

| Display | 40-character alphanumeric LCD with keypad |

| Certifications | Industry standard certifications (CE, UL) |

Related GE modules that complement the 369-HI-R-M-0-0-0-E include:

GE 369-HI-R-M-0-P-0-E – Offers Profibus-DP communication support along with optional metering upgrades.

GE 369-HI-R-M-0-E-0-E – Enhanced model with expanded communication interfaces and metering features.

GE 369 Motor Management Base Unit – Base relay without optional RTD inputs for simpler applications.

GE Multilin 650 Motor Protection Relay – Higher-end relay with advanced motor diagnostics and protection.

GE Multilin 750 Motor Control Relay – Designed for larger motor and generator control applications integrating with the 369 series.

Installation of the GE 369-HI-R-M-0-0-0-E requires ensuring the relay is mounted securely on a panel or DIN rail within a controlled environment to safeguard against dust, moisture, and excessive vibration. Proper wiring of CT inputs, RTD sensors, and communication cables must adhere to GE’s guidelines to maintain signal integrity and safety. Pre-installation checks include verifying compatible control power supply and confirming network architecture for communication compatibility.

Maintenance practices include regular functional verification via diagnostics and software tools like EnerVista 369 to monitor relay health and motor performance. Firmware updates and calibration checks ensure the relay remains accurate and responsive. Periodic inspection of connector integrity and environmental conditions around the relay prolongs its operative lifespan, reducing unexpected downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626