Description

The GE 201CI-1 is a specialized industrial controller used primarily for continuous dissolved gas analysis (DGA) in oil-filled electrical equipment such as transformers. I will now prepare a detailed SEO-optimized product page based on the model GE 201CI-1.

Real-World Use & Application Scenarios

In power generation, electrical utilities, and heavy industry facilities, early detection of equipment faults is critical to preventing costly downtime and catastrophic failures. The GE 201CI-1 is specifically engineered for advanced dissolved gas analysis (DGA) in transformers and other oil-filled electrical assets. By continuously monitoring the concentration of gases dissolved in transformer oil, this controller helps detect insulation degradation, overheating, and potential faults before they escalate.

- 201CI-1

- 201CI-1

Widely used in substations, power plants, and industrial complexes, the GE 201CI-1 plays a vital role in condition monitoring and preventive maintenance programs. It integrates seamlessly into supervisory control and data acquisition (SCADA) systems and distributed control systems (DCS), providing real-time gas level data and comprehensive alarms. Industrial automation engineers rely on this controller to enhance asset reliability, improve operational safety, and streamline fault diagnosis processes. Its ability to monitor and communicate gas concentration accurately makes it indispensable for power system operators aiming to extend transformer life and mitigate unexpected outages.

Product Introduction & Positioning

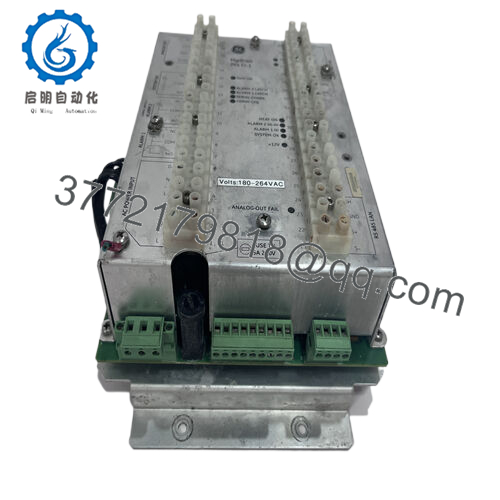

The GE 201CI-1 is a high-precision single-channel remote electronic controller designed to operate with the HYDRAN® 201Ti intelligent transmitter. It serves as an interface and control point, providing gas concentration readings, alarm contacts, and analog outputs in a robust industrial enclosure suitable for outdoor installation.

Functioning as part of the HYDRAN® system, the GE 201CI-1 acts as both a dedicated local display and communication gateway. It connects the 201Ti transmitter to larger monitoring networks, supporting RS-485 and RS-232 communication ports for flexible network integration. This controller is positioned as an access point to a local network of up to 128 transmitters, ensuring centralized data acquisition and alarms handling. Its compatibility with standard industrial power supplies and harsh environments makes it a dependable solution for engineers tasked with continuous asset monitoring and automated fault alert systems.

Key Technical Features & Functional Benefits

The GE 201CI-1 features a digital LED display with a range of 0 to 1999 ppm, providing clear, real-time visualization of gas concentration levels. Its analog output is jumper-configurable to support several industrial standard signals (0-1 mA, 4-20 mA, 0-1 V, 0-10 V) over a 0-2000 ppm measurement scale, enabling seamless integration with control system inputs and SCADA analog channels.

This controller is housed in a NEMA 4X (IP66) steel enclosure designed to withstand outdoor installation in harsh environmental conditions. It supports operating temperatures ranging from -50°C to +55°C and includes an internal heater to maintain operational stability in cold climates—a crucial feature for reliable field deployment.

Communication flexibility is a major advantage, featuring an isolated RS-485 port that supports daisy-chaining of up to 32 controllers and a standard RS-232 port for local computer interfacing. Alarm handling includes gas level and system fault contacts (SPDT relays), which provide both visual indicators and relay outputs for automated response systems.

Reliability and precision are prioritized through extensive diagnostics, fault detection, and rugged industrial design. The GE 201CI-1 reduces manual monitoring needs and enhances proactive maintenance by delivering timely, accurate gas data and alarms.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 201CI-1 |

| Brand | General Electric (GE) |

| Product Type | Single-Channel Remote Electronic Controller |

| Application | Dissolved Gas Analysis (DGA) in transformers |

| Display Type | Digital LED, 0 to 1999 ppm |

| Analog Output | Jumper-configurable: 0-1 mA, 4-20 mA, 0-1 V, 0-10 V |

| Alarm Contacts | SPDT (Form C), 125 VA @ 250 Vac, 60 W @ 220 Vdc |

| Enclosure | NEMA 4X (IP66) steel, baked enamel finish |

| Dimensions | Approx. 250 x 350 x 200 mm |

| Weight | 10 kg (installed) |

| Operating Temperature | -50°C to +55°C (with internal heater) |

| Power Requirements | 100/115/200/230 Vac ±10%, 50/60 Hz, <120 VA |

| Communication Ports | Isolated RS-485, RS-232 |

| Diagnostics | Fault alarms for power, communication, sensors |

| Networking | Supports daisy-chain up to 32 units |

Related Modules or Compatible Units

HYDRAN 201Ti Intelligent Transmitter – Transmitter device that pairs with 201CI-1 for dissolved gas analysis.

GE 201Ci-4 – Four-channel controller for monitoring multiple HYDRAN transmitters.

GE 201Ci-C – Communications controller for managing data flow of several single or multi-channel controllers.

Multilin D20ME – Processor module for larger control systems integration.

GE WESDAC D20ME – High-performance processor module compatible for expanded substation automation.

Installation Notes & Maintenance Best Practices

Installation of the GE 201CI-1 requires a location with protection from extreme mechanical impact, yet allowing access for cabling and ventilation. The NEMA 4X enclosure permits outdoor mounting, but installation should avoid direct exposure to excessive moisture or chemical environments. Use metal conduit for cabling and ensure proper grounding to minimize electrical noise, protecting communication lines and sensor signals. Verify power supply compatibility (100-230 Vac) and provide stable connections following best industrial wiring practices.

Maintenance focuses on periodic visual checks of enclosure integrity, verifying LED display clarity and alarm functions. Communication lines and power inputs should be inspected regularly for wear or damage. Performing software diagnostics via RS-232 or RS-485 interfaces enables early detection of sensor faults or communication errors. Firmware updates and calibration checks are recommended following manufacturer schedules to sustain measurement accuracy and system reliability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626