Description

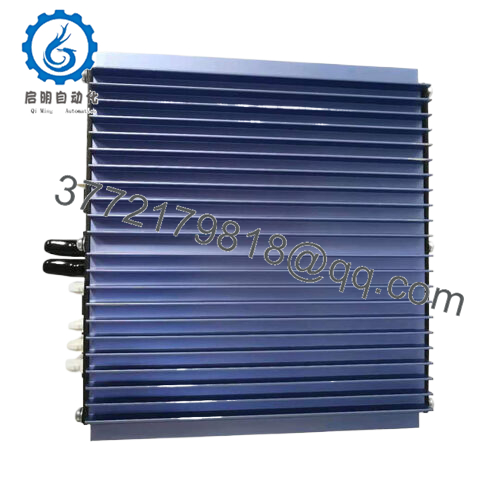

The Foxboro P0922YU FPS400-24 is a high-efficiency 400-watt power supply module, designed specifically for the Foxboro I/A Series 200 Subsystem. It provides 24 V DC output power to the DIN Rail Mounted Subsystem baseplates essential for powering Fieldbus Modules (FBMs), Field Control Processors (FCPs), and other control components in process automation systems. This power supply is especially suited for use in hazardous environments classified as Division 2 and Zone 2, making it ideal for industries like chemical processing, oil and gas, water treatment, and power generation where robust, reliable power is critical for continuous operation.

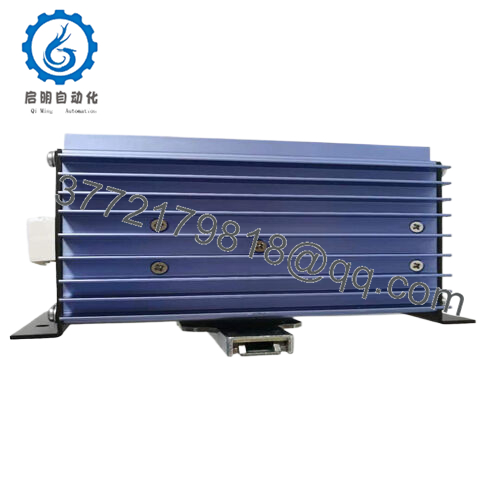

The unit supports a wide input voltage range, accepting 85 to 265 V AC at 47-63 Hz and 108 to 145 V DC, allowing use worldwide across varying power standards. It features an advanced power factor correction circuit that ensures near unity power factor and minimizes electrical losses. Built for harsh industrial environments, the FPS400-24 is housed in a gasketed and sealed extruded aluminum enclosure that provides protection classified as ISA Class G3. The module offers convection cooling without fans, boosting reliability by eliminating moving parts. Installation flexibility is enhanced by its ability to mount horizontally or vertically on a DIN rail or via brackets on a panel or wall.

Major safety features include dual-stage current limiting that protects the power supply from overload conditions and an automatic overvoltage shutdown that prevents damage from voltage spikes. A relay alarm output provides status feedback to the control system, alerting operators to power supply faults. The power supply maintains a stable 24.0 V DC output with tight voltage regulation under varying load and line conditions. Overall electrical efficiency is high, surpassing 90% typical at 230 V AC input.

- P0922YU FPS400-24

| Parameter | Value |

|---|---|

| Model | Foxboro P0922YU FPS400-24 |

| Brand | Foxboro |

| Product Type | 400 W 24 V DC Power Supply |

| Input Voltage Range | 85 to 265 V AC, 108 to 145 V DC |

| Input Frequency Range | 47 to 63 Hz |

| Output Voltage | 24.0 V DC ±0.2 V Nominal |

| Output Power | 400 W |

| Output Current | Up to 16.7 A |

| Efficiency | Up to 92% at 230 V AC input |

| Cooling | Convection cooled (fanless) |

| Environmental Rating | ISA Class G3 (harsh industrial) |

| Certifications | UL, UL-C, CENELEC |

| Mounting | Horizontal or vertical DIN rail, bracket, wall |

| Protection Features | Overcurrent, overvoltage shutdown, power factor correction |

| Alarm Output | Relay (form C) status alarm |

| Dimensions (approx.) | 130 mm H x 55 mm W x 250 mm D |

| Weight | Approx. 2.67 kg |

Related Modules or Compatible Units

Foxboro FPS240-24 – Lower power 240-watt supply for smaller Foxboro 200 Series systems.

Foxboro FPS120-24 – Compact 120-watt power supply option.

Foxboro FBM series modules – Powered fieldbus input/output modules that use FPS400-24 power.

Foxboro FCP series – Field Control Processors requiring reliable 24 V DC power.

Foxboro FEM100 – Fieldbus expansion module compatible with power from FPS400-24.

Foxboro FCM series – Communication modules that operate within the same power system.

Installation Notes & Maintenance Best Practices

Install the Foxboro P0922YU FPS400-24 in well-ventilated industrial control cabinets with proper DIN rail or bracket mounting per layout requirements. Ensure power input connections meet specified voltage and current ratings and confirm grounding and EMS protection to prevent interference. Avoid obstructing airflow around the module to maintain effective convection cooling without fans, supporting temperature stability and extended service life.

Routine maintenance involves periodic monitoring of LED status indicators for output and alarm signals. Inspect electrical connections for tightness and signs of corrosion or damage. Verify the relay alarm functionality for early warning of faults. Regular firmware updates for connected control systems are recommended to optimize power supply integration and fault response. Keeping a spare power supply unit on hand helps reduce downtime during replacement or repair.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626