Description

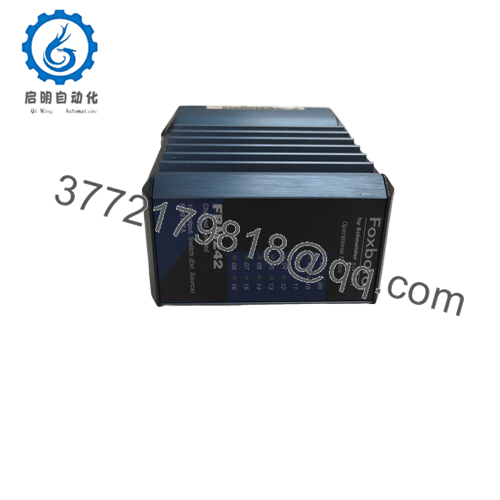

The Foxboro FBM242 RH916TA is a fieldbus interface module and a key component of the Foxboro I/A series distributed control system (DCS). Its main function is to act as a bridge between on-site devices (such as sensors and actuators) and the central processing unit of the control system.

FBM242 RH916TA

In the architecture of the control system, it collects raw data from field instruments, conditions signals, and then transmits them to DCS for further analysis and control operations. FBM242 RH916TA is highly valuable for engineers and integrators due to its versatility and compatibility. It supports multiple input types, including analog and digital signals, and is suitable for various industrial applications. Whether it is a small process control project or a large and complex industrial facility, this module can be easily configured to meet specific requirements, simplify automation processes, and improve overall system performance.

FBM242 RH916TA

Main features and advantages:

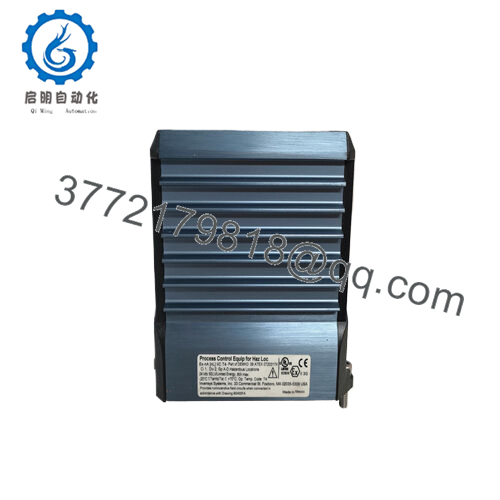

In terms of functional performance, it has high-speed data acquisition capability and can quickly capture and process signals from multiple field devices. This ensures minimal delay in the control loop and enables rapid response to changes in process conditions. Its built-in error checking mechanism ensures data integrity and reduces the risk of erroneous control operations caused by signal failures. The hardware design of FBM242 RH916TA is sturdy and durable, capable of withstanding harsh industrial environments. Its sturdy casing is dustproof, moisture-proof, and vibration resistant, ensuring reliable operation even in challenging environments. The compact size makes it easy to install in the control cabinet, saving valuable space. In terms of compatibility, it follows industry standard communication protocols and can seamlessly integrate with various field devices and other components of control systems. This promotes interoperability and simplifies system expansion. In terms of long-term reliability, this module adopts advanced thermal management technology to prevent overheating and extend its service life. Long term operation in industrial environments will not easily reduce its performance and can provide long-term stable and reliable operation.

FBM242 RH916TA

Technical specifications:

Model FBM242 RH916TA

Brand FOXBORO

Type fieldbus interface module

Power supply 24 VDC

Working temperature -40 ° C to 70 ° C

Installation method: Rack installation

Interface H1 fieldbus RS-485

Certification CE, ATEX (applicable to hazardous areas)

Heat dissipation method: conduction heat dissipation

Protection level IP65

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

FBM242 RH916TA

Application areas:

In power plants, maintaining grid stability relies on precise monitoring of voltage, current, and frequency. The Foxboro FBM242 RH916TA module steps forward to collect and process these critical electrical signals with extremely high precision, ensuring the efficient and safe operation of the power distribution system.

On the other hand, chemical plants face the challenge of handling large quantities of hazardous chemicals. Here, the FBM242 RH916TA module plays a critical role in monitoring the temperature, pressure, and flow of chemical processes, preventing potential safety hazards, and ensuring compliance with regulatory requirements.

In the oil and gas industry, which has a wide range of operations and is often located in remote areas, this module can achieve real-time monitoring of pipeline conditions, wellhead pressure, and tank levels. It can interface with various sensors and transmitters, becoming an indispensable asset in these industries, helping to seamlessly integrate into existing control systems and enabling operators to make informed decisions quickly.

FBM242 RH916TA

Related products:

Foxboro FBM201- It is an early module in the same series, suitable for simple control applications that only require basic input-output functions.

Foxboro FBM247- This module complements FBM242 RH916TA by providing additional analog output functionality, achieving more comprehensive process control.

Foxboro FBM231- This module is designed specifically for digital input-output operations and can work in conjunction with FBM242 RH916TA to manage discrete signals in industrial processes.

Foxboro FBM217- This module is suitable for temperature measurement applications and can be integrated with FBM242 RH916TA to accurately monitor and control temperature in various industrial environments.

Foxboro FBM223- This module provides high-density analog input channels and can expand data acquisition capabilities when used in conjunction with FBM242 RH916TA.

FBM242 RH916TA

Installation and maintenance:

Before installing the Foxboro FBM242 RH916TA, careful planning of the rack layout is necessary. Ensure there is sufficient space around the module for proper air circulation to prevent overheating. Carefully check the grounding of the control rack, as good grounding is crucial for protecting the module from surge effects and ensuring the accuracy of signal processing. When connecting on-site devices to modules, please carefully check the wiring diagram to ensure correct polarity and connection type. During installation, be careful when handling modules to avoid electrostatic discharge, as it may damage their sensitive electronic components.

In terms of maintenance, regular visual inspections should be arranged to check for any physical damage, loose connections, or abnormal indicator lights. Regularly conduct diagnostic tests to check the communication and data acquisition functions of the module. Keeping module firmware updated is also important, as new versions typically include performance improvements, security patches, and enhanced compatibility with other system components.

FOXBORO Other product models:

Foxboro 127S-2EA5

Foxboro FBM232-P0926GW

Foxboro FBM232

Foxboro IGP10-A22D1F-M2

Foxboro E69F-T12-RS

Foxboro RH924YA

Foxboro FCP280

Foxboro P0926GX

Foxboro FCP280

Foxboro FDC280

Foxboro P0926GX

FOXBORO H92 P0928DU

FOXBORO IMT33A-HA54300110002

FOXBORO H90 H90C9AA0117S

Foxboro IDP10-AF1C01F

Foxboro P0912XX

FOXBORO P0912XX

FOXBORO IDP10-AF1C01F

Foxboro E69F-T-I2-J-R-S

Foxboro IDP10-AF1C01F

Foxboro FBM232 P0926GW

Foxboro FCP270 P0917YZ

Foxboro H90JE9A001J0

Foxboro H90JE9A001J0

Foxboro E69F-B12-MRS

FOXBORO E69F-TI2-JRS

FOXBORO FBM217

FOXBORO FBM218/237 P0916QD RH101AY

Foxboro 127S-2EA5

Foxboro FBM232-P0926GW

Foxboro FBM232

Foxboro IGP10-A22D1F-M2

Foxboro E69F-T12-RS

Foxboro RH924YA

Foxboro FCP280

Foxboro P0926GX

Foxboro FCP280

Foxboro FDC280

Foxboro P0926GX

FOXBORO H92 P0928DU

FOXBORO IMT33A-HA54300110002

FOXBORO H90 H90C9AA0117S

Foxboro IDP10-AF1C01F

Foxboro P0912XX

FOXBORO P0912XX

FOXBORO IDP10-AF1C01F

Foxboro E69F-T-I2-J-R-S

Foxboro IDP10-AF1C01F

Foxboro FBM232 P0926GW

Foxboro FCP270 P0917YZ

Foxboro H90JE9A001J0

Foxboro H90JE9A001J0

Foxboro E69F-B12-MRS

FOXBORO E69F-TI2-JRS

FOXBORO FBM217

FOXBORO FBM218/237 P0916QD RH101AY

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626