Description

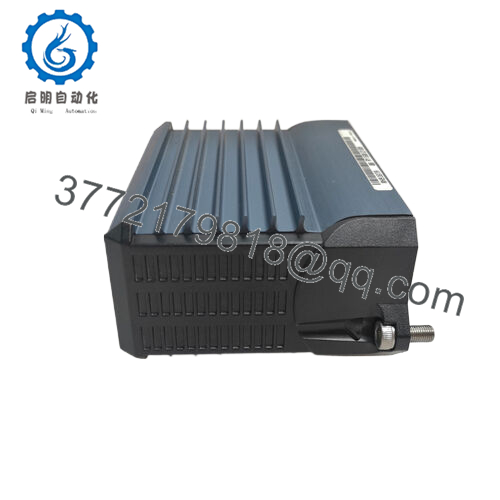

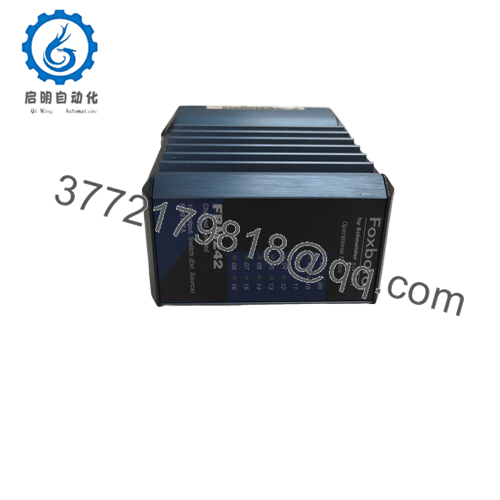

In industrial automation, where discrete actuators like solenoids and relays demand unwavering command execution to prevent erratic machine behavior or safety interlocks from failing, engineers routinely confront the pitfalls of non-isolated outputs that invite noise coupling, ground faults, or overloads in expansive control networks, eroding process control precision and inviting unplanned halts. The FOXBORO FBM242 RH916TA confronts these issues as a sixteen-channel discrete output interface module, supplying galvanically isolated switching for externally sourced loads that upholds signal reliability without propagating faults across shared circuits. This module emerges as a cornerstone in deployments such as modernizing conveyor sequencing in mining operations or fortifying alarm panels in wastewater facilities, where coordinating dozens of on/off devices under variable electrical stresses requires fault-tolerant I/O to dodge production snags. Envision a steel rolling mill with synchronized valve banks exposed to inductive kicks and harmonic distortion—the FOXBORO FBM242 RH916TA channels precise DC or AC pulses to effectors, quelling transients that could otherwise spark spurious trips and cascade into mill downtime. Centering on imperatives like modular scalability and diagnostic transparency, it equips teams to erect resilient automation frameworks that evolve with throughput demands, curtailing the rework of daisy-chained wiring prone to voltage sags. For veterans in industrial automation and process control, the FOXBORO FBM242 RH916TA is pivotal amid shifts to high-density I/O racks, where its channel isolation thwarts common-mode interference, preserving high-reliability outputs in EMI-saturated zones. It dovetails with aims of streamlined loop management, offering per-channel status feedback that pinpoints actuator stalls before they compound, all while embracing external excitation for flexible voltage matching. Fundamentally, this module recasts output orchestration from a fragility to a fortress, granting you the latitude to hone sequential logics over fretting about electrical echoes in rigorous process realms.

- FBM242 RH916TA

- FBM242 RH916TA

The FOXBORO FBM242 RH916TA delivers sixteen discrete output channels configured for external sourcing, where field power from user-supplied supplies drives loads through the module’s optically isolated switches, preventing backfeed into the I/A Series backplane and safeguarding the controller from surge reflections. Anchored in the peripheral I/O tier of the automation stack, it latches onto a baseplate carrier linked to the fieldbus backbone, conversing with processors like the FCP280 via HDLC protocol to receive setpoint commands and relay feedback on channel states, enabling closed-loop verification for sequences like pump startups. Each output—rated for dry contacts or wet switching—operates independently, with built-in fuses and surge suppressors that handle inductive turn-offs up to 60 VDC or 240 VAC, while group isolation applies across all channels when leveraging a common external bus. In a standard layout, it complements input siblings like the FBM207 for bidirectional control, supporting redundancy through dual-carrier mirroring where a failover unit assumes duties sans perceptible lag, and diagnostics stream via the DCS engineering station to log overcurrent events or open-wire faults. HART isn’t native here, but Modbus TCP extensions allow overlay for remote polling if needed, keeping the focus on raw switching vigor. Picture it orchestrating a batch filler: the FOXBORO FBM242 RH916TA energizes fill valves on demand from the controller, monitors coil integrity through sense lines, and flags diagnostics to the network—all while its rugged shell shrugs off enclosure vibrations. This baseplate-bound stance in I/O hierarchies optimizes cable economy by localizing outputs near effectors, easing expansion without backbone strain, and empowering you to layer in safety-rated logics atop basic on/off duties in versatile industrial setups.

| Specification | Details |

|---|---|

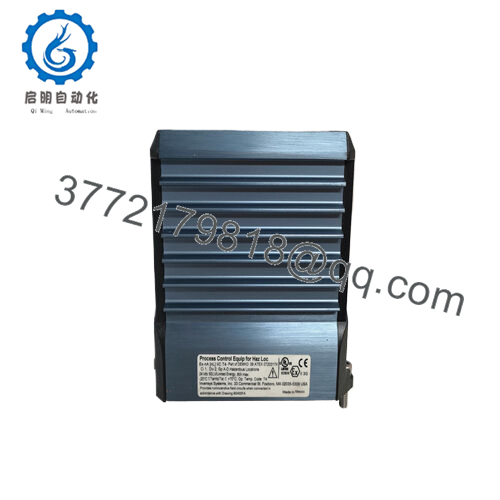

| Model Number | FBM242 RH916TA |

| Brand | FOXBORO (Schneider Electric) |

| Type | 16-Channel Discrete Output Module (Externally Sourced) |

| Input Voltage | 24 V DC (Module Power) |

| Operating Temp Range | 0°C to +60°C |

| Mounting Style | Baseplate Snap-in |

| Dimensions | 147 mm x 51.5 mm x 114 mm |

| Weight | 0.6 kg |

| Interface/Bus | I/A Series Fieldbus |

| Compliance | CE, RoHS, ISA S71.04 (G3 Harsh) |

| Supported Protocols | Modbus TCP (Optional) |

| Typical Power Draw | 8.5 W |

Incorporating the FOXBORO FBM242 RH916TA fortifies output dependability that underpins seamless discrete control, as its per-channel galvanic barriers quarantine faults to individual effectors, averting ripple effects that could destabilize adjacent loops and curbing nuisance alarms in synchronized sequences. Tailored for the grind of frontline automation, it sustains output fidelity through electrical flux and mechanical jostles, which prolongs relay life and obviates the need for auxiliary snubbers, handing maintenance schedules back to condition-based rhythms over calendar-driven overhauls.

Isolation’s ripple extends to integration fluidity, where the module’s external source compatibility spans legacy DC banks to modern AC grids without adapter sprawl, lightening design loads during panel refreshes and accelerating commissioning in phased rollouts. Diagnostics embedded in each channel—via LED arrays and bus telemetry—expedite root-cause hunts, like isolating a stuck solenoid amid a bank of 16, which trims resolution windows from hours to minutes and amplifies uptime in throughput-critical flows.

The payoff crystallizes in a more cohesive control narrative: the FOXBORO FBM242 RH916TA not only executes commands with poise but elevates them, channeling reliable switching that accrues into amplified efficiency and tempered risks for forward-leaning engineers.

In automotive assembly halls, the FOXBORO FBM242 RH916TA governs robotic grippers and conveyor diverters in I/A Series outstations, delivering isolated pulses for precise part placement under arc-welding EMI, bolstering critical system uptime in high-speed, 24/7 takt-time process control environments.

Pharmaceutical tablet presses embed it for punch sequencing and reject arm actuation, where the module’s harsh-rated shell endures cleanroom vibrations while ensuring fault-free outputs compliant with GMP traceability, ideal for batch-to-batch transitions demanding rapid, reliable discrete commands.

Mining ore crushers integrate the FOXBORO FBM242 RH916TA into breaker controls, switching high-inrush motors via external DC feeds amid dusty, shock-laden shafts, supporting modular I/O expansions that maintain fast-cycle interlocks for overload protection in continuous extraction ops.

FBM241 RH916NG – Eight-channel sinking output variant for lower-density, space-constrained actuator groups.

FBM243 RH917XA – Sixteen-channel relay output model for dry-contact isolation in signal relay applications.

FBM207 P0916JS – Complementary sixteen discrete input for balanced bidirectional monitoring in sequence controls.

FBM230 P0926GU – Fieldbus manager add-on for HART-enhanced discrete networks in smart effector setups.

FBM242 P0916TA – Base configuration without RH revision for standard voltage ranges in legacy upgrades.

FBM219 P0917LE – Twenty-four input/eight output hybrid for alarm-heavy panels with mixed needs.

P0926GH – Terminal assembly companion for secure external source wiring in high-vibration zones.

FBM201 P0916AA – Eight analog input expander for correlating discrete states with process variables.

Before slotting in the FOXBORO FBM242 RH916TA, map your external source voltage to the channel ratings—15-60 VDC or up to 240 VAC—to preclude overstress, and tally total load current against the 2 A per channel cap to dodge thermal trips. Align the baseplate with your carrier’s slot config, ensuring fieldbus addressing doesn’t clash with upstream FBMs, and probe the 24 VDC rail for <5% ripple to sustain clean switching. Torque terminal screws to spec (0.5 Nm) post-wiring, and simulate a few cycles dry to vet sense feedback before live tie-in.

Upkeep revolves around tri-monthly LED sweeps for stuck states, zeroing in on outputs driving inductive loads where arcing might carbonize contacts—a quick resistance check across fuses flags preemptively. Biannually, amid light loads, cycle all channels via DCS scripts to benchmark response times, and swab terminals with ESD-safe cleaners if dust accumulates in open enclosures. For the FOXBORO FBM242 RH916TA, harvest fault logs quarterly to trend failure modes, like voltage sags on shared buses, informing fuse upsizes or source tweaks. This pragmatic cadence, armed with a loop tester and no frills, keeps outputs crisp without commandeering outage slots.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626