Description

FOXBORO FBM232 P0926GW is a high-performance Ethernet communication module designed specifically for the Foxboro I/A series and EcoStruxure ™ Foxboro ™ Designed as a component of the DCS system. It serves as an important link, providing a single port Ethernet interface between single port field I/O devices and the overall control environment.

FBM232 P0926GW

This module is designed to support Ethernet communication speeds of 10 Mbps or 100 Mbps, ensuring fast data transmission. It can connect to a single copper Ethernet network (whether it’s a 10 Mbps or 100 Mbps network) to communicate with various devices. By acting as a bridge, it enables on-site equipment to communicate with the central control system and integrate its data into the Foxboro DCS control database.

For engineers and system integrators, FOXBORO FBM232 P0926GW is a valuable asset. It supports multiple communication protocols, such as Modbus TCP/IP and EtherNet/IP, and has high versatility. This means it can interface with devices from different manufacturers, promoting interoperability in multi vendor industrial environments. It simplifies the process of building and maintaining complex control systems by providing reliable and standardized communication methods. Whether upgrading existing industrial networks or building new control systems from scratch, FOXBORO FBM232 P0926GW has the ability to effectively meet communication needs.

FBM232 P0926GW

Main features and advantages:

From a functional perspective, FOXBOROFBM232 P0926GW stands out with its high-speed data transmission capability. It supports 10 Mbps or 100 Mbps Ethernet communication and can process large amounts of data in real-time. In busy industrial environments, multiple sensors and actuators continuously send and receive data, ensuring that there are no bottlenecks and enabling quick decision-making. For example, on high-speed production lines, it can quickly transmit data from sensors that monitor product quality, and if any problems are detected, it can immediately adjust the production process.

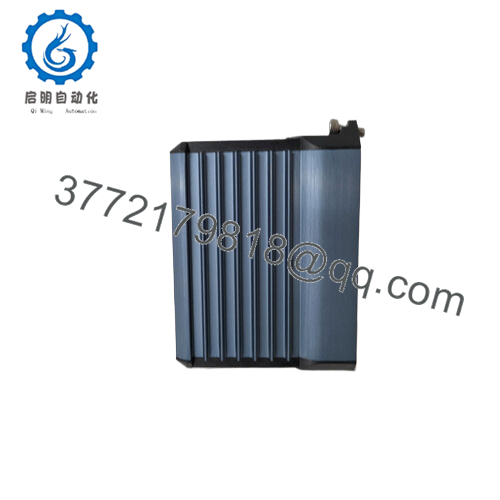

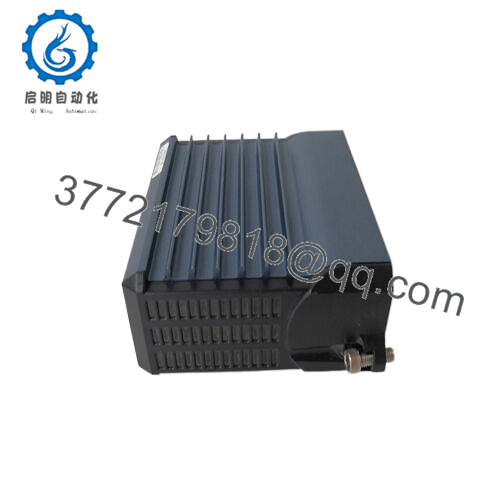

The hardware design of this module is sturdy and durable, capable of withstanding harsh industrial environments. It has a G3 level (harsh) environmental rating and can withstand dust, moisture, extreme temperatures, and vibrations. This makes it suitable for installation in factory workshops, outdoor processing plants, or areas near heavy machinery. Its compact size also facilitates integration into existing control cabinets, saving valuable space. The DIN rail installation design further simplifies the installation process, allowing for quick and safe installation onto standard industrial mounting rails.

Compatibility is one of the advantages of FOXBORO FFBM232 P0926GW. It supports a wide range of I/O protocols, which is a great boon for industrial applications. This means that it can communicate with various on-site devices, regardless of the protocol requirements used by these devices. Whether it is legacy devices using old protocols or advanced sensors using the latest communication standards, this module can establish connections. It can also connect up to 64 external devices, expand the coverage of the control system, and achieve comprehensive monitoring and control of multiple components in industrial installations.

The design of this module ensures long-term reliability. It has built-in functions to prevent electrical interference and ensure stable communication. For example, it may have isolation mechanisms to shield common electrical noise in industrial environments. With proper installation and maintenance, FOXBORO FFBM232 P0926GW can be used in industrial control systems for many years, providing a consistent and reliable communication solution. This reliability is crucial in industries where downtime may result in significant economic losses, such as continuous process manufacturing or power generation.

FBM232 P0926GW

Technical specifications:

Model FBM232 P0926GW.

Brand FOXBORO

Type Ethernet communication module

Power supply 24 VDC

Working temperature -40 ° C to+70 ° C (-40 ° F to+158 ° F)

Installation method: DIN rail

Dimensions 102 mm (4 inches) x 45 mm (1.75 inches) x 104 mm (4.11 inches)

Weight 284 g (10 ounces)

Interface RJ-45 Ethernet (10/100 Mbps), may have other auxiliary interfaces under specific configurations

Supports protocols Modbus TCP/IP, EtherNet/IP, and may also support other protocols depending on software configuration

Maximum number of connected devices 64

Maximum data transfer rate of 100 Mbps (also supports 10 Mbps)

Humidity 0% to 95% RH without condensation

contact us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

FBM232 P0926GW

Application areas:

Taking the oil and gas industry as an example. The vast pipeline network, refineries, and drilling platforms here require extremely precise monitoring and control. FOXBORO FBM232 P0926GW. can bridge the gap between various on-site equipment and central control systems. It connects sensors that detect pipeline pressure, temperature, and flow, and transmits these critical data in real-time to the control room. This enables operators to make informed decisions quickly, ensuring the safe and efficient operation of the entire infrastructure. For example, once a sudden drop in pipeline pressure is detected, measures can be taken quickly to prevent potential leaks and costly interruption accidents.

In power plants, whether it is coal-fired, gas-fired power plants, or renewable energy plants such as wind and solar power, FOXBOROFBM232 P0926GW. is equally indispensable. It can achieve communication between numerous components within the power plant, such as turbines, generators, and transformers. By transmitting data related to power generation, equipment performance, and grid stability, it helps optimize energy production. For example, in a wind farm, this module can communicate with various wind turbines to collect data on their speed, blade angle, and power generation. Then use this data to remotely adjust the settings of the turbine, maximizing energy capture and grid integration efficiency.

The water treatment and sewage treatment industries are also highly dependent on FOXBORO FBM232 P0926GW.. In sewage treatment plants, numerous pumps, valves, and sensors are working. This module connects these devices to achieve seamless transmission of data related to water quality, flow rate, and chemical dosage. This ensures that the treatment process is carried out efficiently, and the discharged water meets safety standards and regulatory requirements. If the pH value of the treated water begins to deviate from the optimal range, the sensor connected through FOXBORO FBM232 P0926GW. can quickly send this information to the control system, triggering corrective measures such as adjusting the chemical dosing pump.

FBM232 P0926GW

Related products:

FOXBORO FBM230 P0926GU – This is also a communication module from FOXBORO. Although FBM232 P0926GW. focuses on Ethernet communication, FBM230 P0926GU provides serial communication capability. Both can be combined in control systems to support devices with serial and Ethernet connections, expanding the system’s connectivity options.

FOXBORO FBM207B – This is a discrete input module that can work in conjunction with FOXBORO FBM232 P0926GW. FBM232 can transmit input data from FBM207B (with sixteen discrete inputs) to other parts of the control network. This integration enables seamless transmission of discrete input data, such as the status of switches or sensors, to the central control system.

FOXBORO FBM217- Another discrete input module with thirty-two discrete inputs. FOXBORO FBM232 P0926GW can be configured to transmit data from FBM217, ensuring effective management of all discrete input data sources in the control system. The combination of these modules helps to build a comprehensive input monitoring solution.

FOXBORO FBM241C – a discrete input module with eight discrete inputs. FOXBORO FBM232 P0926GW can be used to transmit data from this module, adding more input sources to the data acquisition system in industrial control settings. It enables the inclusion of more input sources in the overall control process.

FBM232 P0926GW

Installation and maintenance:

It is crucial to carefully plan the layout of the control cabinet before installing FOXBORO FBM232 P0926GW. Ensure there is sufficient space around the module for proper ventilation. Due to the potential generation of heat during module operation, good air circulation helps maintain optimal operating temperature, preventing overheating and potential performance degradation. When installing the module onto the DIN rail, please ensure that the rail is securely installed and can withstand the weight of the module and any additional connecting components.

Pay close attention to the wiring connections. Ethernet cables should be routed correctly to avoid interference with other electrical cables in the control cabinet. Use high-quality Ethernet cables that are suitable for industrial environments and meet the required specifications. The correct grounding module is crucial. Follow the provided guidelines and local electrical regulations, and use appropriate grounding conductors. This can protect the module from electrical surges and ensure reliable communication.

For maintenance, it is recommended to conduct regular visual inspections. Check for any signs of physical damage, such as cracked casing or loose connections. Check for signs of corrosion or dirt on the RJ-45 port, as these can affect the quality of Ethernet connections. Signal diagnosis should be conducted regularly. This may involve using specialized software or testing equipment to check the integrity of data transmitted through Ethernet ports. Ensure that the communication performance of the module meets the requirements, without packet loss or delay.

Firmware updates are an important component of maintaining module performance. Stay up-to-date with the latest firmware releases from FOXBORO and update according to recommendations. These updates typically include error fixes, performance enhancements, and compatibility improvements. Before updating the application, be sure to back up any important configuration data. Carefully follow the update procedure to avoid any issues that may affect the operation of the control system.

FOXBORO Other product models:

Foxboro 127S-2EA5

Foxboro FBM232-P0926GW

Foxboro FBM232

Foxboro IGP10-A22D1F-M2

Foxboro E69F-T12-RS

Foxboro RH924YA

Foxboro FCP280

Foxboro P0926GX

Foxboro FCP280

Foxboro FDC280

Foxboro P0926GX

FOXBORO H92 P0928DU

FOXBORO IMT33A-HA54300110002

FOXBORO H90 H90C9AA0117S

Foxboro IDP10-AF1C01F

Foxboro P0912XX

FOXBORO P0912XX

FOXBORO IDP10-AF1C01F

Foxboro E69F-T-I2-J-R-S

Foxboro IDP10-AF1C01F

Foxboro FBM232 P0926GW

Foxboro FCP270 P0917YZ

Foxboro H90JE9A001J0

Foxboro H90JE9A001J0

Foxboro E69F-B12-MRS

FOXBORO E69F-TI2-JRS

FOXBORO FBM217

FOXBORO FBM218/237 P0916QD RH101AY

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626